How to get a pump out of the well: professional advice

Let's now try to figure out together how to get the pump out of the well and whether it needs to be done at all in cases when it has ceased to function. Perhaps the reason for stopping the water supply is not at all in it, but in the electric cable or process automation system.

In order to understand this, you need to clearly understand the source device and the wiring diagram, which will be discussed now and, moreover, you can watch the thematic video in this article as additional material for clarification.

Arrangement and repair of the water supply system

Some possible reasons for stopping

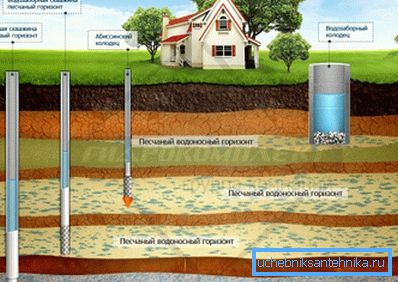

Note. The borehole is primarily different from the water well with a small diameter and, in almost all cases, a greater depth. Drilling can be carried out on the sand, or to the artesian aquifer, which is much deeper.

- If your pump does not pump water from the well, then this does not mean that it has failed and needs to be changed, so let's take one step at a time. First of all, you should take into account the factor that you have a well - on the sand or artesian, since in the first case the silting of the filtration layer is possible and the pump can not cope with the thick liquid.

- Another possible reason that the pump does not work in the well may be a malfunction in the terminal box on the top of the well if the cable was connected through it (there could be a splice using a heat shrinkable coupling, and there are practically no problems). In any case, the electric cable will be short and it will have to be increased and the instruction assumes to do this through such terminals, although this is not the best option.

- Before pulling the pump out of the well, you should also pay attention to the pressure switch, as the unit may not start due to the fact that there is no minimum starting limit. There can be several reasons for this: failure of settings, oxidation of contacts, and complete sensor failure. In addition, you need to determine whether the voltage is applied to the electrical cable at all (this can be done with an ammeter-voltmeter (tester)).

- Only after checking all these nodes and factors can the unit be pulled out of the well. Please note that this will have to be done together with the trunk pipe, so for this kind of work you need at least two people.

We get the pump from the well

The question of how to suspend a pump in a well is identical to the question of how to remove it, since the assembly and disassembly are carried out in the same way. The main retainer for the unit is a steel cable, one end of which is attached to the eyelet on the body, as shown in the photo above, and the other to the wellhead.

In the diagram, you see the structural components of the wellhead and, although its lid may not have a round, but an elongated shape (cable gland may extend to the side), everything else remains the same. So, the steel cable is attached to the eyebolt and, just like on the pump casing, is clamped with special clips (the clip for the cable is made according to its diameter).

Note. In most cases, an electrical cable is fastened to the steel cable using clamps with either ordinary copper or aluminum wire, so you will pull them together.

We figured out the cable and now we need to figure out how water is taken - through the caisson (pit) or adapter, as this will fundamentally change the way the unit is removed from the well.

If the line is discharged through the caisson, then in 99% of cases it is a 32 mm diameter polyethylene pipe. And the first thing you need to do is to cut this hose in the pit, stepping back from the 15-20 cm casing.

After that, you need to fill the sticking pipe into the service pipe and only then lift the pump itself with a cable, pulling it up.

To do this, unscrew the cover, but do not remove the cable from the eyebolt - if it slides out when you lift it up with your own hands, it will still linger on this mount, so you will not have force majeure.

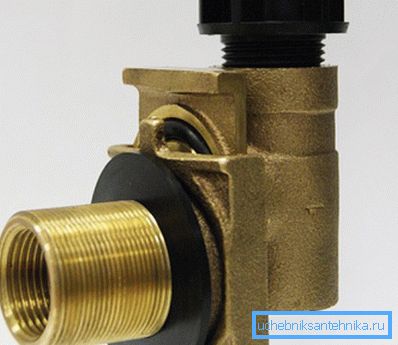

But if the main pipe for water intake is connected via an adapter, then here you cannot do without a rod with an external thread on one end. The fact is that the adapter consists of two parts, where one is firmly attached to the production pipe, and the other to the nozzle that connects it to the submersible pump.

Between themselves, these two elements are connected with a sled joint - the clutch is quite tight, especially since there is necessarily a special waterproof lubricant.

On the upper part of the adapter, which is attached to the nozzle, there is a special hole with internal thread for fixing the rod. Therefore, you will have to find the right rod (a metal pipe, and you can cut the necessary thread yourself) and, lowering it into the well, fasten it to this hole.

After you hit the thread and screw the rod, try to pull it all up, just do not swing it, so as not to damage the thread or the adapter itself.

Most likely, the adapter will not be disconnected from the first time, since it is rather difficult to remove the pump from the well - the salts contained in the water slag the connection, and it must be moved.

Therefore, you will have to make a few strong movements upward to disengage the adapter, and perhaps even use some homemade winch or jack for this.

Recommendation. If you cannot disconnect the adapter, use two ordinary jacks for assistance. To do this, you will need a crossbar with a collar that will grab the bar and two T-braces under it. Place jacks under these props or in their place and gradually raise them to avoid a strong bias - the adapter will necessarily disengage.

Most likely, those who were involved in the installation knew which pump to put on the well and its diameter is several centimeters smaller than the pipe section. Therefore, the rise should occur without complications, except in the first case, the pipe will rub against the production pipe.

Conclusion

In conclusion, I would like to remind once again that you are not in a hurry to get the submersible pump when it stops, but first make sure that the other nodes are working. Still, the price of such a unit is not a cheap one, and the labor costs associated with its dismantling are also considerable. Successes!