How to make a caisson for a well - tips and a practical

After developing a water source, it should be properly equipped. The main task for regions with a continental climate is to protect the well from winter frosts and spring floods, so we decided to tell you how to make a caisson for the well, since it solves this problem perfectly.

Caisson

Purpose

The first and most important purpose of the caisson is to protect the internal space from groundwater and flood waters, as well as from precipitation. The second purpose is to protect the tip against freezing in winter..

We all know from the physics course that water freezes at zero degrees Celsius, and after freezing it cannot flow through pipes. Moreover, during crystallization, the water expands and breaks any container in which it is located, so an unheated well can be destroyed by frost.

To protect the structure and equipment from the effects of low temperatures, it is necessary to warm that part of it that is above the level of soil freezing. This role is perfectly handled by a small room, equipped around the wellhead and insulated with good thermal insulation material.

In addition to frost, there is another danger: the penetration of sedimentary, flood or groundwater into the aquifer. Most often this occurs due to loose plugging of the annular space of the well, or lack thereof, because water easily penetrates into the gap between the casing and the wall of the shaft. It then flows down the outer side of the casing, infecting the aquifer with riding mud.

Here again, the construction of the premises around and above the wellhead can help, which will be able to hold back the pressure of the flood and rains, as well as prevent flooding of the mouth of the object.

Note! It is quite possible to make a caisson structure with your own hands, because it does not require too much responsibility and accuracy, and also does not have a complex structure, therefore, in the case of mistakes made, nothing terrible will happen.

Construction and variations

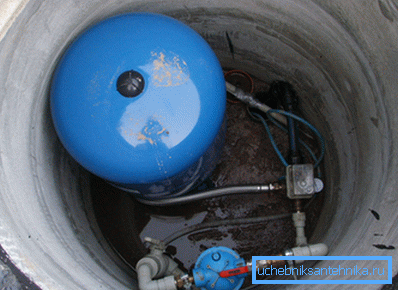

The design of the caisson structure is not regulated and can have almost any shape. The dimensions of the room are chosen such that the caisson equipment for the well fits into it, and at least one person can fit in for repair and maintenance of the object.

At high groundwater levels, the walls of the caisson structure should be additionally waterproofed to protect against pressure water, and all joints should be carefully sealed and sealed. If the water level in the soil is not high, it is enough to protect the structure from capillary moisture and make a dense roof with an airtight hatch.

Note! As a rule, the structure is lowered below the level of soil freezing by 50 to 200 cm in order to provide a reserve in case of emergency low frost. Also, water pipes will be located just below the height of frost penetration, and it is easier to connect them at a certain height above the floor.

There are no additional requirements for the design of the caisson, so it can be made from a variety of materials using various construction technologies.

There are such main varieties:

- Caisson for metal wells. Metal caissons for wells are performed by electric arc welding of a cylindrical or rectangular space around the top of the casing. Cylindrical structures made of large-diameter steel pipes and steel sheets for the formation of the bottom and roof are most applicable: they are durable, strong, reliable, but are afraid of corrosion and retain heat poorly;

- Brick room. An excellent, reliable and warm option, however, the price of a brick and its laying makes this method not the most popular among well owners;

- Caisson for wells from concrete rings. One of the most reliable and durable structures, however, the presence of joints between the rings slightly reduces the tightness of the structure, and the weight of concrete rings requires lifting equipment and inflates the cost of loading and transporting concrete goods;

- Monolithic concrete structure. The most acceptable variant in terms of price / reliability, since it has no joints and is connected by a reinforcement cage, and manufacturing does not require the work of specialists or the purchase of finished products;

- Plastic container. The most suitable option for areas with high groundwater, as it is completely sealed and not subject to corrosion. The disadvantage is low strength and good thermal conductivity.

Production of monolithic caisson

If you are ready to work on your own, our concrete caisson assembly instruction will help you:

- First of all, we dig a hole according to the size of the future construction and fill it with construction polyethylene. If equipment is planned to be placed inside, then the minimum dimensions are 1.5x1.5x2.4 m. We do the depth taking into account the bedding of gravel 20 cm high, the floor level should be two meters below the freezing level;

- We compact the bedding and begin to build the reinforcement cage for the walls. We use rods with a diameter of 12 mm, the grid width is 30x30 cm, the distance to the walls of the pit is at least 70 mm. The rods are knitted with steel wire or welded;

- We build formwork 50 mm from the reinforcement cage of walls from old boards and sheets of plywood. The shields are covered with plastic wrap from the inside and knocked down in the form of a cube without a bottom and roof, in the places of the communications entrance we insert plastic or metal sleeves. It is better to make all the formwork at once, to fill the structure in one go;

- Fill concrete form M400 or higher into the formwork, it is better to add hydrophobic additives. We use vibrating tools for compaction; we align the upper edge of the walls by level (it is easier to do at the construction stage of the formwork);

- We are waiting for concrete hardening, then dismantle the formwork and proceed to the construction of the roof. To do this, at the level of the upper edge of the walls of our structure, we make the flooring of durable boards (thickness - 50 mm), which is supported on bars with a section of 150x150 mm or steel pipes. We cover the flooring with a double layer of polyethylene and leave it as an external formwork for the wall of the pit, in the center of the roof we insert a box for the hatch;

- We lay the reinforcement mesh, which we associate with the frame of the walls, and fill the slab. Insert the sleeve for the withdrawal of ventilation and watering tap. After the concrete has set, we dismantle the formwork, the box and the flooring from the boards, and lay a hole for the hatch with a brick to a height of 3 rows;

- The above-ground part of the building is carefully waterproofed with mastic or a penetrating compound, and around the concrete box we make a small insulated blind area. But we recommend to deepen the roof under the ground, and to insulate the walls and ceiling from the inside with a five-centimeter layer of expanded polystyrene. Next, install a sealed hatch and a pipe for ventilation, which we cover with a lid;

- The places of pipe entry are sealed with mortar and foam.

Note! At the end of construction, when the concrete is completely strong, the roof of the well construction should be covered with a good layer of bitumen and covered with polyethylene from the walls. Then you can caisson prikopat layer of clay.

Conclusion

If you want to build a reliable and durable water supply system in the Russian climate, you can not do without a caisson. Following our leadership, you can build one of its most reliable types - a monolithic caisson. For those who are interested in the details, the video in this article is attached.