How to make a drill for a well at home

In order to equip an autonomous water supply system in a garden plot, it is not at all necessary to construct an expensive artesian well, the price of which may be incompatible with the needs of water supply. It would be more reasonable to make a shallow well on the sand, the resources of which are quite enough to supply water to any seasonal dacha.

Provided that the groundwater is located at a shallow depth, and the composition of the soil at the site does not contain rocks and consists mainly of sandy and clay layers of soil, such a well can be made independently using simple drilling devices.

Manual drilling

This article will discuss how to make a drill for drilling wells up to 20 meters deep without using special heavy equipment.

The reader will be offered instructions for the manufacture of three types of self-made devices for manual drilling of wells, which are most common among owners of garden plots.

In addition to the description, this article contains drill drawings for a well with their own hands, according to which, if you have experience in metal work, you can make an uncomplicated drilling tool on your own.

Cable drilling

This type of drilling is convenient because it does not require the manufacture of any special devices, and the drilling rig can be assembled from scrap materials. In addition, it allows you to perform all the work yourself without help.

The essence of this type of drilling is as follows:

- A heavy pipe with a pointed end is dropped into a well from a great height.

- Under the action of its weight, when the pipe wall falls to the bottom of the well, the wall of the pipe cuts into the body of the face, and some of the soil enters the pipe.

- After that, the pipe is again raised to a certain height and abruptly dropped down.

- Gradually, the well deepens, and the bottom of the face accumulates in the shock tube.

- After several blows, the pipe is removed to the surface with a manual or electric winch to clean it.

- After lifting the impacting head, it is retracted to the side and cleaned of the drilling rock with several blows of a heavy hammer, and then the whole process begins anew.

Impact drill

Thus, drilling continues until the required well depth is reached.

Next, it will be described how to make a drill for drilling wells using a percussion cable method, as well as how to make the simplest drilling rig:

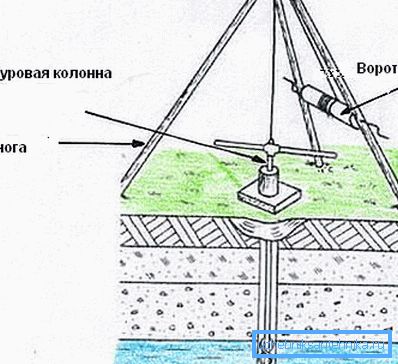

- Install a tripod with a height of 2–3 m above the prospective drilling site.

- At its top, you need to fix the unit for the rope, and attach a manual or electric winch to one or two supports.

- Impact drill is a thick-walled pipe, which with its diameter must match the diameter of the future well bore.

- To the upper end of the pipe perpendicular to its longitudinal axis, it is necessary to weld a strip of thick metal with a hole, the diameter of which should correspond to the thickness of the hoisting rope. The hole should be placed along the center line of the pipe.

- At the lower end of the pipe must perform an annular or gear sharpening. If possible, after sharpening it is desirable to temper the end in a muffle furnace.

- To facilitate cleaning of the soil in the upper part of the pipe, you can make a slot or drill a few radial holes.

Tip! If the power of the winch permits to speed up the work, you can increase the weight of the impact drill by installing additional removable metal weights in its upper part.

Rotary drilling

This type of work is characterized in that the working tool cuts into the ground and removes the residual rock under the action of rotational forces. To do this work, as a rule, two people are involved who are located on both sides of the drill rod and rotate it with the help of a long scrap or steel pipe.

Thus, a shallow water well on the sand can be made in a short time without using any additional equipment. All that is needed for this is a hand-held drill of the required diameter, a rod for building up the length of the working tool, two pipes for turning a sufficient length and several days of free time.

Spiral drill

For manual drilling of wells in light, non-stony soils, one of two types of working tools is most often used: spiral and spoon drill.

Spiral (it is also called auger) auger in the working position is a vertical rod of a thick-walled tube, at the bottom of which a carbide cutting tool is installed. Spiral strips of hardened steel welded along the bar up from the cutting edge.

During rotation, the cutting edge cuts the ground, and the spiral strips push it upward, thereby creating an additional stop in the direction of drilling. In the process, residual soil from the well accumulates between the turns of the screw, so it must be periodically pulled to the surface for cleaning.

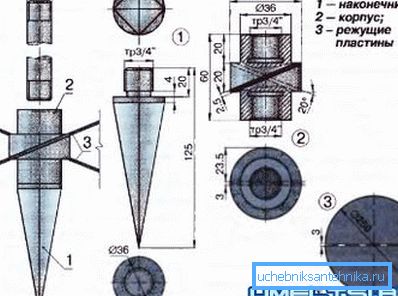

Before you make a drill for a well, you need to prepare a thick-walled pipe of the required length and a metal disk made of steel 4-6 mm thick, with an outer diameter equal to the diameter of the well.

- The lower end of the pipe must be sharpened or welded into it sharpened tip of hardened steel.

- Cut a metal disk in half and on the cutting edge of each half perform a smooth or gear grinding.

- Weld the halves of the steel disk to a vertical rod at a distance of 125 mm from the pointed end on opposite sides at an angle of 70 ° to its longitudinal axis. Thus, the angle between them should be 40 °.

- At the top of the bar install a threaded coupling to build it along the length.

Tip! As parts for the auger, you can use a saw blade cut in half from a circular saw of the appropriate diameter.

Spoon bur

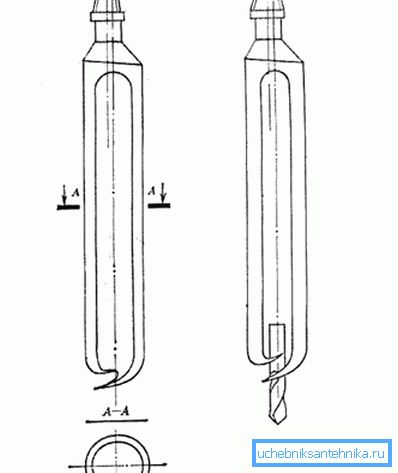

For work in soft, resistant to the fall of clay or sandy soils, you can use a spoon. It is convenient in that the opening of the soil is carried out not only the lower but also the side cutting edge, collecting the selected rock inside the cylinder. Cleaning it also requires periodic removal of the working tool from the well to the surface.

To make such a device, you need a thick-walled pipe of suitable diameter, a welding machine and a standard set of plumbing tools.

- In the pipe section it is necessary to make a longitudinal slot in accordance with the drawing.

- Use a heavy hammer and flat-tipped scrap to give the pipe the required cross-section.

- Sharpen the lower and side cutting edges.

- At the bottom of the pipe along its longitudinal axis, weld a thick drill with a diameter of 18-36 mm.

- Weld a vertical bar to the top of the pipe. The longitudinal axis of the rod should be shifted in the direction relative to the longitudinal axis of the working tool by 10-15 mm.

If possible, it is recommended to perform hardening of the cutting edges of any drilling tool.

Tip! The width of the slit in the pipe depends on the composition of the soil and is chosen empirically. The drier and loose soil is on the site, the smaller the width of the slot should be

Conclusion

After reading this article, you can come to the conclusion that under favorable geological conditions, it is possible to make a shallow well on your own garden plot using one-two people using self-made equipment.

Additional information on this issue can be obtained by watching the video in this article or by reading similar materials on our site.