How to make a shower cabin with your hands at the cottage:

With the beginning of the summer season, many compatriots in the family circle make a decision - we make a shower in the country house with our own hands, so that the design is working, easy to use and inexpensive. Many manage to achieve the desired result, while other gardeners have to buy factory-made showers, the price of which is high.

In this article we will talk about what to make a shower in the country and what schemes to use during the installation work in order to guarantee an optimal result. The topic of the article is of considerable interest, as a self-made shower, provided it is properly assembled, is no worse than a factory counterpart.

Again, the price of the factory cabin is several times higher than the cost of materials that can be spent on the construction of a homemade shower.

Important: If you consider that living in a country house is temporary, the safety of a shower stall purchased in a specialty store will be a big question. In other words, the cabin installed on the site in your absence can simply be carried away, while hardly anyone will covet the improvised structure.

So, we decided to do a country shower with our own hands, as it is profitable and easy. It remains to determine the features of the construction work.

Choose a type of soul

Before making a shower in the country, we decide on the choice of a suitable modification.

In accordance with the design features, there are two main categories:

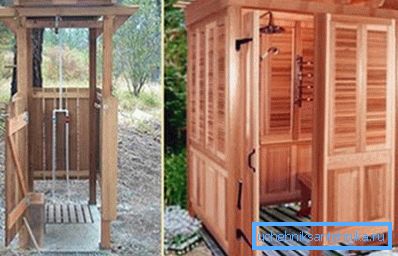

- Open shower - a simple construction that consists of a water supply and supply system, a panel or rack, a drain and a sewage drainage system.

In this case, the panel or stand is attached to the fence or to the wall of the country house. For ease of use around the improvised soul, you can equip a lightweight quick-release barrier. The advantage of this solution is the ability to dismantle the shower panel and turn off the water supply due to the end of the summer season.

- Closed wash cabin - This is a more capital structure, which is a frame from all sides sheathed by one or another material. Such a shower differs from the previous modification only by a fence on all four sides and, as a result, by the possibility of a separate (non-wall) location.

In accordance with the peculiarities of the implementation of water supply, shower facilities are divided into the following categories:

- Modifications with cold water supply from the central water supply and hot water from the flow or storage heater.

- Modifications with cold water supply from the central water supply system or from the well to the accumulation tank installed over the cabin.

In this case, the capacity allows not only to accumulate the required amount of water, but also to warm it by means of sunlight.

- A separate type of structures with a storage tank is a shower-toptun. In this case, the tank does not necessarily bring up the cabin, but can be placed directly on the ground. The mechanism is driven by the weight of the person and the water from the reservoir enters the watering can. A shower toptun is a good solution for wooden-framed cabs designed for substantial mechanical loads. Also such equipment can be used together with wall racks and panels.

So, we decided on the design features and equipment of shower facilities, it remains to determine the features of the assembly work.

Build an open wall shower

The assembly instruction for the wall construction is not particularly complex.

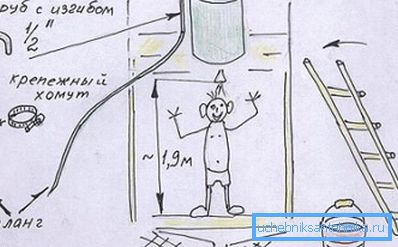

- At the initial stage it is necessary to arrange water supply.

- After the water supply is arranged and the pipes are brought to the level of the location of the connecting fittings on the panel, we proceed to waterproofing the surface on which the installation will be carried out.

Excessive humidity can cause premature damage to the wall or the fence which will be fixed plumbing.

Waterproofing shower finish in the country is made of bitumen mastic, followed by lining ceramic tiles (if the wall is stone or brick).

If the surface on which the installation is wooden, as a waterproofing for the shower, you can apply antiseptic and polymer penetration of deep penetration, which fill and strengthen the pores in the thickness of the wood.

- A panel or a rack is fastened on top of the prepared surface and the fittings are connected to pre-supplied pipes.

- A wooden ladder is assembled from the boards, between which and the ground there should be a gap of at least 5 cm.

- In the lower part of the open shower, a drainage drain filled with rubble is arranged, or a ditch is simply settled to drain water.

Build a closed cabin

After we have decided on the arrangement of an open shower, let us consider what the assembly instruction for a closed washing cabin is. Installation instructions depend largely on the type of cabin and the type of materials used.

A simple, closed washing booth can be assembled from steel, aluminum pipe and lumber. Each of these materials has its own obvious advantages and some disadvantages.

Based on the combination of price and quality, the best option is to build a simple, but stable construction from a steel corner with a shelf width of 5 cm. The use of aluminum pipe is a good solution, but the price of the finished solution will be high due to the considerable cost of colored metal. The use of sawn timber is little justified, since wood is quickly destroyed due to excessive moisture.

The installation instructions for the cabin from the steel angle are as follows:

- Prepare 4 pieces with a length of 2.25 meters.

- Prepare 8-12 lengths of 1.5 meters.

- From short segments we collect two squares, which will serve as the lower and upper trim.

- From the inside, at the corners of the finished straps, we weld long sections of the corner, which will serve as vertical posts. As a result, we should have a parallelepiped-shaped structure.

- Throughout the frame we drill through holes with a diameter of 1 mm.

- From polycarbonate we cut sheets of plating with dimensions of 2 * 1.5 meters.

- We attach the prepared sheets to the corner with pre-drilled holes and fasten to the screws, which should enter into the holes.

Important: The screws are twisted so that there is a small gap between the cap and the surface of the polycarbonate. This gap is necessary to compensate for thermal expansion. If the gap is not maintained, in the heat of the polycarbonate can be deformed and cracked.

- Instead of one of the walls we make a hinged door. However, you can do it easier and pull the clothesline, which will hold the curtain of plastic film.

- On the top trim we mount a storage tank with 3 inserts: an upper tie-in for water, an upper tie-in for air access and a lower tie-in for connecting the water intake fittings.

Conclusion

It is not difficult to make an open or closed shower cabin, and therefore it is possible to do without buying expensive ready-made structures. With a set of conventional tools that are in any household, you can assemble a cabin that will not yield to the factory analogues in anything.

There are questions that need clarification? More useful information can be found by watching the video in this article.