How to make a sidebar in the plumbing - features of work

As a rule, when installing a water supply system, a situation arises when you need to connect the system to the main line. Often, homeworkers this task baffles, but the professional plumbers in this case there are some tricks. Below we will share with you some of them.

General information

The need to connect a tap on a plot or inside a house may appear when connecting a tap to the water supply, additional plumbing equipment, household appliances, etc. On the plot, a tie-in may be required when connecting a new building, for example, a bath or summer kitchen.

If we are talking about connecting the system with the central highway, then before you start work, you need to get the appropriate permission. Sometimes people do not know how to legitimize the tie-in to the water supply system and do it without permission, which ultimately leads to fines. In reality, there is nothing difficult in this - it is only necessary to contact the local authorities and the organization of water supply.

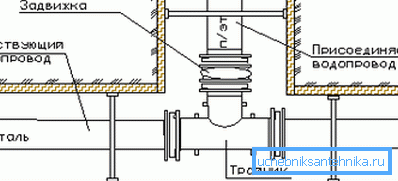

Insert into the central highway

The process of tie-in in the first place can be divided into two types:

| Without pressure | In this case, the flow in the central highway is blocked for the duration of the work. |

| Inset under pressure | It is performed in cases where there is no possibility to turn off the water. |

Below we take a look at both options for doing this work.

Without pressure

This process depends a lot on the material from which the pipes are made, however, the principle is always about the same. Therefore, as an example, consider a sidebar in the steel line.

So, the instruction looks like this:

- First of all, you need to expose the section of the highway on which the tie-in. For this you need to dig a pit with dimensions of about one and a half and a half meters. As a rule, at first the excavation is digged with the help of an excavator, but after reaching a special metal tape, workers take up shovels. After the tape usually remains to dig another 30-50 centimeters.

- Next, usually digs a trench to the object that will connect.

- Then turn off the water in the system.

- After all the excavation work has been completed, a hole is cut in the main pipe using autogen and a branch pipe with a cut pipe thread is welded to it.

- Then a valve is attached to the nozzle, which allows the flow to be shut off for further work.

- At the end of this operation, a well is installed over the tie-in site.

If the pipe is made of polyethylene or another type of plastic, then welding is not necessary. In this case, use special tools - nurses for tapping into the water supply. This fitting is a tee, the nozzles of which are disassembled into two halves.

Note! According to the existing construction standards, the diameter of the outlet must be less than the diameter of the highway.

After installing the seat, a hole is made in the plastic pipe. Further work looks like when working with a steel pipeline.

No overlap

The removal device under pressure is quite operational and productive method.

However, this work requires precise adherence to technology and all the nuances that are given below:

- First of all, at the site where the pipe will be drilled, it is necessary to remove the insulation and thoroughly clean the surface.

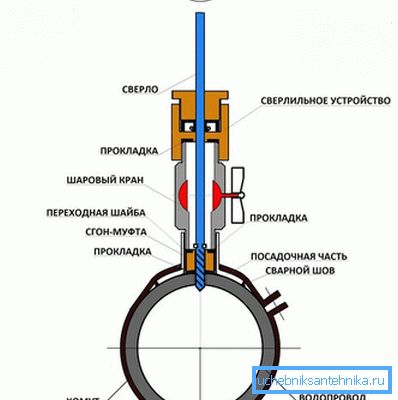

- Next to the trunk pipe is installed saddle for tapping into the water supply.

- The fittings and a special device for drilling are attached to the branch pipe of the outlet.

- Then through the open valve and the gland of the fixture the cutter of the required size is inserted.

- After drilling the hole, the cutter is pulled out and the valve is closed.

- At the end of the operation, the drilling device is removed.

If the pipe is steel, then it can be welded to it and continue to perform the same steps. As in the previous case, a well is necessarily installed at the site of the withdrawal.

Tip! The water supply well is easiest to make from concrete rings. At the same time in the lower ring it is necessary to make cuts for pipes.

Inset into the internal water supply

In some cases, it is necessary to branch off the internal pipeline.

This can be done in two ways:

- With the help of tie-in tee;

- By installing a curved fitting.

Below we consider both options.

Tie-in tee

The technology of this method is extremely simple - a section of the pipe is cut and a tee is installed in its place. The method of insertion depends on the material from which the pipe is made.

I must say that in practice the work is quite difficult. In particular, it is often complicated by the proximity of the system to the wall. Therefore, this method has recently been used quite rarely.

With a curved flange

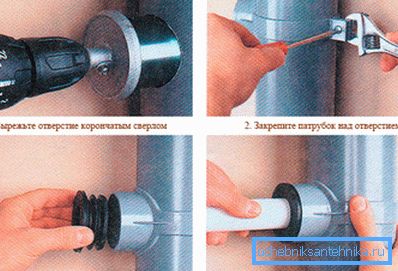

A simpler way to install a tap that does not require pipe cutting is to use a curved fitting with a hose clamp. Moreover, the price of this part is not more than the usual tee for pipes.

This process looks like this:

- The first step is to shut off the water in the pipeline.

- Then you need to drill a hole with your own hands.

- After this, the joint between the fitting and the pipe is lubricated with silicone sealant.

- Further the fitting is established and tightened by a collar.

Note! The semi-circular cut-out of the fitting should match the diameter of the pipe.

I must say that for the internal arrangement of the outlet, you can also use the saddle, as for the highway. Kits are available for sale, which in addition to the saddle contain a locking mechanism and a milling cutter. Thus, the device allows you to perform a tie-in, without blocking the water.

Here, perhaps, all the main points of connection outlet. Of course, you can entrust this work to specialists and especially not to bother with all these nuances. However, you should first know the cost of the tie-in to the water supply system, and it may still make sense to do it yourself.

Conclusion

Despite the apparent complexity, tapping branches into the plumbing is quite simple. Moreover, this process depends on the conditions in which the work is performed, as well as the material from which the main line is made.

You can read more information on this topic from the video in this article.