How to make water from a well for year-round use

Many developers who built a well in a country plot, sooner or later think about conducting a water supply system directly to the main building some time after its construction. To this end, it is recommended to use the winter version, which involves laying pipelines at a certain depth. That is, the elements must be in the non-freezing layer.

Advantages of this method

The well is a hydraulic structure that allows the extraction of groundwater. During erection, a vertical recess is made in the ground, the walls of which are reinforced with various materials.

This option has many positive aspects.

- The possibility of building with your own hands allows you to do without the involvement of specialists from the outside, which means that there is a significant savings.

- The price of the materials used is not very high, making it possible to obtain inexpensive, but quite efficient hydraulic structures.

- The independence of the system from external factors provides an opportunity to carry out maintenance and repair work at a convenient time.

- After installation, there is no need to pay for the used volume of water, although there will still be some expenses during operation.

Note! Unlike an artesian well, the costs of constructing a hydraulic structure of this type are much lower. For extraction of water, it is enough to install a low-capacity deep-well pump.

Base events

After getting acquainted with the advantages of this option, it is necessary to elaborate in more detail on how to conduct water supply from the well to the house independently. Each stage must be considered separately in order to better understand the process. Initially it is assumed that the hydraulic structure already exists on the land plot.

System design

When building a network to provide the structure with water, proper project drafting is an important point. Each object has its own characteristics, therefore, in case of failure to comply with certain rules, all sorts of difficulties appear.

The following are the main steps.

- First, certain requirements for communication systems are identified, as well as their operational parameters.. The technical assessment carried out at the design stage allows to improve the quality characteristics of the network, thereby reducing the cost of future repairs.

- Next, the total water consumption and quantity is calculated by individual nodes.. Correct calculations will improve the efficiency of the system. In addition, a detailed study will provide an opportunity to provide items with increased load to carry out the distribution.

- After that, a diagram of the entire network is drawn up, where the main elements and nodes will be reflected, and an estimate with approximate cost calculations. At this stage, you need to decide on the materials and equipment used.

Attention! Before laying the water supply system from the well to the house, it is necessary to familiarize yourself with the points of SNiP 2.04.02-84, where the main information about the external networks is indicated.

Pipeline Laying

Delivery of the working environment is carried out using conductive elements in the form of pipes made of metal or polymeric material. Metal-plastic products are most often installed, as they are resistant to chemical and mechanical influences.

First, a trench is being dug, the depth of which will exceed the level of soil freezing. Otherwise, in the winter time, water may freeze inside the pipelines. However, when using a special cable, this distance is quite realistic to shorten, especially when it comes to regions with a cold climate.

In case of need, observation wells are arranged. They are usually located in places where the branch turns, diverges or deepens. With their help, you can reach difficult places.

Below is considered how to lay a well under the water supply for maintenance and inspection of important components.

- The first step is to prepare a pit 11 m. Its depth should be 30-40 cm more than the level of soil freezing in a particular region. At the bottom is required to pour a layer of sand 10-15 cm.

- At the second stage, the foundation of concrete is laid, which will be able to withstand the brickwork. The foundation can be made in the form of a tape or a solid platform.

- Next, walls are built with a thickness of one brick, that is, 250 mm. Elements are laid by alternating spoons and butt rows until the structure reaches the top.

- At the last stage, the floor slab is laid with the hatch directly on the side planes of the structure.

Note! Before numbering wells in the water supply network, it is necessary to calculate their total number and purpose. Pipelines can branch not only horizontally, but also vertically on the site.

After the erection of the viewing structures, they are transferred to the immediate pipe-laying in the prepared trench. Inside the wells, elements are connected by means of adjustable or docking fittings, depending on the situation. The most commonly used parts are compression type.

For water intake from the well a hole is made corresponding to the diameter of the water pipe.

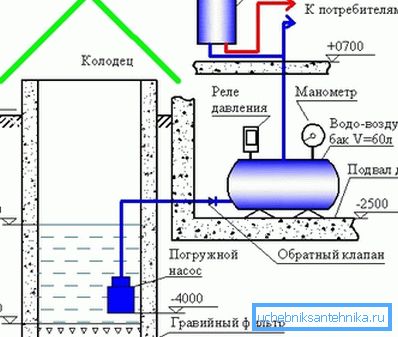

Submersible Pump Installation

The hydraulic device for pumping fluid is suspended using a special cable. For the retaining element, the frame is usually made of steel corners and placed on concrete rings. Fixation is carried out using anchors.

The pump is placed at the end of the pipe fragment with which it will be joined to the corner. After that the cable for connection to the electrical network is unwound. A check valve is installed at the outlet, protecting the system from the opposite flow of water.

A brass or plastic coupling is attached to the non-return valve, to which the pipe itself is fixed. Electrical cable is attached to it by means of insulating tape. The assembled structure is lowered into the well. The edge of the tether joins the metal frame.

After that, the horizontal section of the pipeline must be docked with the horizontal part using an angle element. As for the electrical cable, it can be directly brought out through the top or entered into a prepared trench. (See also the article Water supply for irrigation in the country: features.)

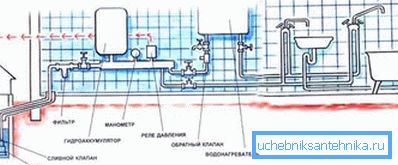

Equipment installation process

Pump automation should be as comfortable as possible; therefore, a hydroaccumulator is installed, which is a special container partially filled with water. A certain volume is air. When water becomes less, the pressure decreases, and when the level rises, vice versa.

Such a device is a transfer point between the consumer and the source. The greater the membrane tank, the less will be the inclusion of an electric pump, and therefore, the probability of its failure significantly decreases. Tank capacity typically ranges from 50 to 200 liters.

The installation of the device is carried out indoors, as it is necessary to prevent the likelihood of a liquid freezing. The device allows you to stock up on a certain amount of water in the event of a power outage, while the pump will not function.

The control element is a pressure switch, which allows you to turn on the hydraulic device when the amount of liquid decreases and turn it off when filling the tank. Electromagnetic product is installed on top of the pump in a horizontal position.

System testing

After connecting the equipment, it is necessary to verify the operability of the water supply network. If all elements are functioning properly, and the pipelines do not leak, then you can carry out the final work.

Conductive elements are wrapped with geotextile and covered with a layer of sand. The resulting mound is covered directly with the soil that was removed before. Manholes are installed on the manholes, if any, in the plumbing system.

Final part

Many developers are thinking about how to make a summer water supply system from a well in order to irrigate a vegetable garden and supply household buildings with liquid only in the warm season.

In this case, it is possible to refuse the deepening of pipelines and the installation of additional equipment. However, the principle of installation remains the same, which reflects this instruction. You can read the details on the video in this article.