How to make your own forms for well rings

An autonomous source of drinking water at a country site is a good alternative to central water supply. Very often, a well or a well is the only way to get water not only for human consumption, but also for watering the garden. Despite the fact that the wells are gaining more and more popularity, traditional wells still should not be discounted.

The simplest version of such a source is from concrete rings. Forms for the production of well rings can be purchased ready-made or do it yourself. The article will explain in detail how to do it yourself.

General information

The classic shape for well rings resembles a cylinder, but there are also rectangular options. It should be noted that they can also be with and without a lock.

In traditional products, the end face is flat. If a lock is provided, then they are endowed with docking ends. According to experts, in this case, the rings appear better tightness, and reliability of the whole system.

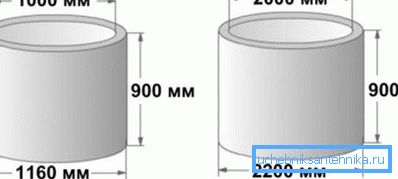

Standard sizes of base rings are divided into groups:

- great - weight 1.5 t, internal diameter 2 m;

- average - weight is 1 t, height - 900 mm, internal diameter - 1.5 m;

- small - weight 600 kg, height 900 mm, wall thickness - 160 mm, internal diameter - 1 m.

In addition to the standard well rings, the production of wall pillars, which differ in height and are used to create a well sector, protruding above the surface of the site, is adjusted. They have a lower height than the standard ones. An important element of the construction of the well - the bottom and well cover, included in the kit and having a certain diameter.

Annually, the production of reinforced concrete rings becomes better due to the constant introduction of new developments. For example, when laying metal fittings, laser cutting is now used. Innovations contribute to the manufacture of high-quality and reliable products. Due to simplified production, the final cost of reinforced concrete rings is steadily declining.

We make rings for a well from can / w

In this case, you need to purchase or manufacture, and maybe rent a special form of well rings. To create the outer and inner diameter using metal formwork.

In the free space between the sheets of formwork install wire or reinforcing mesh frame, and then the entire structure is poured concrete solution. It is best to compact the form with a vibrator, if it is not at home, then it is carefully made with a wooden bar.

You must remove air from the mixture so that the concrete is compacted as best as possible. If you do everything correctly, you will end up with a very durable product that can withstand heavy loads and perform its function quite effectively.

When self-manufacturing products, often establish special suspension brackets. At manufacturing enterprises special faltsevy locks are often put. This allows the design to have a tight and reliable fixation of the trunk, which eliminates the displacement of its elements.

Technology

Tip: do not rush, the main thing is to carefully observe all stages, then you will get the expected result.

Below is a step-by-step instruction.

At first glance, it is difficult, but in the manufacturing process you will realize that everything is easier than it seems.

- To create the shape of a concrete ring for a well, pick up 2 metal barrels that will fit it, usually their throwing price. The fact that they will have a technological stamping will not affect the manufacturing process. If you do not find a barrel, you can take the air ducts or pipes of the desired diameter. Collect the formwork cylinders and by joining together the individual sheets. A good result is observed in formwork created from plastic cylinders.

- Make on the outside of the outer barrel of the future form two longitudinal markings that will divide it vertically into two equal halves.

- Take a pair of door sheds and install them on the markings so that their curves are on top and along the markings, and the shutters are located at the edges from the line. Attach the canopies by welding or rivets.

- Copy the markup on the inner ring of the formwork. In the place of installation of awnings from only one side, cut the lower caps of the bend on each side.

Tip: during work, be careful not to damage the outer ring.

- Remove the cut spindles and unfold the resulting shape. Fix the closure of the valves will be cut off spindles or others, but suitable in diameter.

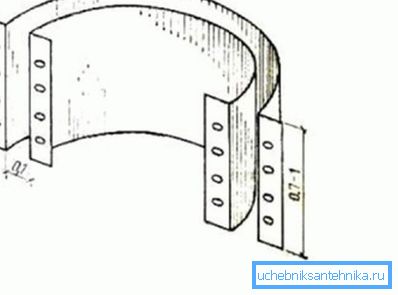

- Prepare the inside. Use a prepared mold or a metal barrel for this. Draw inside two marking lines, which are spaced from each other on a segment of 1/3 of the circumference. Make sure that the cylinder does not split vertically into equal parts, the difference between the width of one part and the other should be almost 2 times larger. Install awnings on the inner formwork as well as outside.

- Copy the markup from the inside to the outside. Then cut the cylinder carefully along the lines so as not to disturb the internal canopies. Cut off the spindles, pull them out and develop the resulting shape. Match the comparability of the parties. Ensure that the assembled inner formwork is 50-100 mm higher than the outer one. The outer part of the structure should be easy to open, close and lock. Internal - easy to open inside.

After releasing the ring, first remove the inner shape. Then free the canopies from the spindles, collect the smaller part of the form inwards and pull them out of the fresh product, remove the outer part by opening it outside. This form for the production of well rings can be used repeatedly.

Conclusion

Making a form for a well concrete ring is easy. To do this, you need to choose the appropriate metal sheets and assemble them in a certain order. In the presented video in this article you will find additional information on this topic.