Inch crane: constructional and operational features

In this article we will discuss the main differences between the inch measurement system and the metric one. We will also consider the features of the choice of valves for the pipeline.

The topic of the article is of considerable interest, since a wide range of plumbing equipment is presented on the market, the dimensions of which are not determined in the usual millimeters. For example, you can find a half-inch crane for sale, and what do you think this size means?

The difference in measurement values

In order to immediately clarify the difference in measurement values, we note that the inch measurement system is traditionally used in the construction of pipelines and in the selection of stop valves.

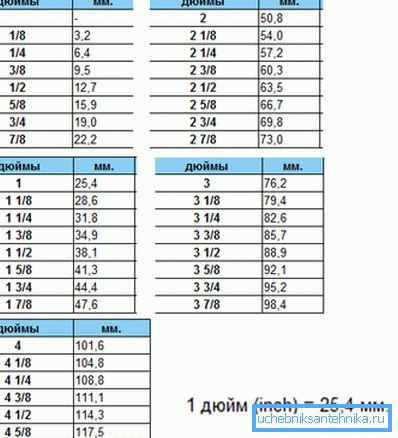

English inch (inch) is denoted by writing as equal to 25.4 mm in the metric measurement system. Thus, it is not difficult to convert the current values used in the selection of pipes and fittings into millimeters, it is enough to equip with a calculator.

For example, let's calculate what analogue metric measurement system corresponds to a 2 inch tap. To do this, 25.4 multiply by 2 and get 50.8 mm.

So, the calculation instructions are theoretically simple, and it is also easy to calculate the dimensions of an inch tap. It remains to consider how these quantities are combined with the size of the pipes.

Features of the diameter of the pipeline

As already mentioned, it is easy to calculate how much a tap is 1 2 inches in mm. But, what is necessary to know in order to pick up valves for the pipeline?

Currently, when building in-house water supply networks, the most popular solution is metal-plastic, polypropylene, less often all-metal steel or copper pipes.

It is no secret that all these pipes with a similar outer diameter will have a different internal diameter, since the steel pipe will be thinner than a similar product made of polymeric materials.

Therefore, when determining the dimensions of the pipeline and its compliance with the dimensions of valves, it is necessary to take into account the following values:

- wall thickness;

- inner diameter - conditional characteristics of pipeline elements, both pipes and fittings;

- nominal diameter (Dу) - the nominal value of the internal diameter, indicated in millimeters and rounded to the whole value;

- nominal diameter Dn;

- outside diameter.

From the above, it follows that if the valve is 1 8 inches (internal diameter) with internal thread is female, then the external diameter of the pipe with external thread should also be 1/8.

Accordingly, we look at the previously given table, how much will be 1/8 and see 3.2 mm. That is, we got the diameter of the inside of the faucet and the outside of the pipe in millimeters.

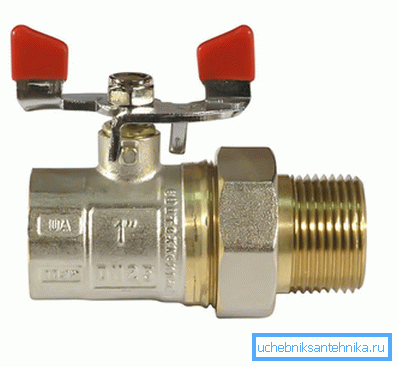

Device of the inch spherical crane

When we say a crane an inch and a quarter, we often mean the so-called half-turn locking devices with a ball-type shutter. Consider how this equipment is arranged, and what you need to keep in mind when choosing it.

The ball valve is a type of pipe stop valves, the locking element in the construction of which is made in the form of a sphere.

Today, half-turn valves with spherical valves are considered one of the most modern, progressive and at the same time simple to install and maintain types of valves. Such cranes are commonly used in the construction of pipelines transporting liquid and gaseous media.

The movable ball-shaped shutter has a through axial bore, which in a certain position coincides with a through bore in the body of the crane. When the holes coincide, the flow of water passes freely, while at the same time, if the holes in the housing and in the gate do not coincide, the flow is blocked. For example, the gate valve will be completely closed if the ball is rotated 90 degrees around its axis.

A full bore valve is equipped with a barrier sphere with a through hole diameter similar to the inner diameter of the nozzle, which is connected to the pipeline.

Due to the compliance of the parameters of the hole parameters of the pipeline minimizes the level of hydraulic losses, which distinguishes these devices from other types of valves. Therefore, the ball valve is currently used as the main type of locking device on the linear sections of gas pipelines.

An important element in the design of the ball valve are "saddles", made of fluoroplastic rings. The presence of "saddles" provides a full junction of the bolt and housing, tightness, smoothness and ease of rotation of the tube.

Important: The presence of PTFE seats limits the temperature of the transported medium to + 200 ° C.

Summing up the above, we note the advantages characteristic of ball valves of the ball type:

- simplicity of the device;

- tightness of the housing and the shutter;

- compact dimensions;

- the simplicity of the configuration of the flow part and the almost complete absence of stagnant zones;

- ease of management;

- limited time required to perform the turn of the shutter;

- possibility of operation during transportation of viscous media, sludge, suspensions, pulps, etc.

Important: Such devices are characterized by one major drawback - the presence of a "dead" zone when turning the bolt with a cantilever flywheel. This inconvenience is quite compensated by a crane equipped with a flywheel-lamb.

Device and operation of the valve crane

Along with valves, it is impossible not to note the presence of valve taps, which are commonly used in the construction of household and industrial pipelines.

Among the advantages of this type of valves are the following:

- high degree of maintainability in comparison with ball counterparts;

- affordable price;

- a wide range of offers due to the variety of modifications;

- ease of installation;

- possibility of use as a shut-off and control valves (for comparison, a ball valve is only shut-off valves).

Among the drawbacks, we note lower durability in comparison with ball counterparts. On the other hand, the device, if necessary, can be disassembled, find out the cause of the breakdown and repair it yourself.

A conventional single-valve valve consists of the following structural elements:

- housing made of copper, brass or stainless steel;

- spout (separate or inseparable from the body);

- flywheel attached to the rod;

- the locking mechanism is a crankshaft of a worm or ceramic type.

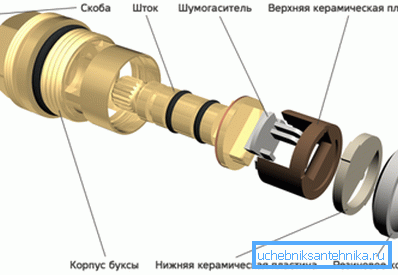

As already mentioned, in valve-type devices, two types of locking mechanisms are used. Consider the features of their application.

The worm-type locking mechanism is driven by several turns of the flywheel around its axis. The worm rod at the end opposite to the flywheel is equipped with a rubber or leather gasket.

The gasket is in the process of rotation adjacent to the "saddle" and thus closes the water supply. Conversely, if you rotate the flywheel in the opposite direction, the gasket moves away from the “saddle” and the water passes unhindered.

Important: The most common problem in such mechanisms is the thinning of the gasket and, as a consequence, the occurrence of leaks. The repair instructions are simple, it is enough to disassemble the valve, remove the old gasket and install a new gasket in its place.

The locking mechanism in the form of a ceramic crane box is a more progressive option in comparison with a worm-type device.

The shutter is a core with two combined ceramic plates, one of which is stationary, and the second rotates around its axis. In the process of turning the stem of the plate are combined or, conversely, between them there is a gap, through which water flows.

Among the advantages of this type of gate, the following should be noted:

- low torque, because the device is half-turn;

- durability of the shutter due to the fact that the ceramic parts are much stronger than the rubber gasket;

- ease of repair, as the shutter is not repaired, but changes entirely, despite the fact that its price is low.

Conclusion

So, now we have a general idea of what constitutes a crane 3 4 inches and similar products with other sizes. Again, we considered the features of the device locking devices adapted for installation on inch pipes.

Have any questions? You will find more comprehensive answers by watching the video in this article.