Insert into the water supply system - the main features of

In order to establish uninterrupted water supply in a private house and in a suburban area, it is required to connect to water supply utilities. This type of work is quite complicated, as evidenced by the fact that inserting into the water supply system under pressure with your own hands is prohibited, this should be done by an organization that has the appropriate permission. But in order to save, you can spend all the preparatory work yourself, so we will consider the features of the connection in more detail.

Types of existing pipelines

The method of work depends on the material of the laid highway. Most often one of three options meets:

| Cast iron pipelines | This option is found in old communications. Working with him is quite difficult due to the large wall thickness in the structure and properties of the metal. Cast iron is quite fragile, so when digging a trench with your own hands you need to be done carefully so as not to damage the main |

| Steel systems | One of the most common options today, widely used in Soviet times. It has a very high strength, but in the process of use in the metal there are corrosion processes, because of which the quality of water deteriorates significantly |

| Plastic pipes | This option is used today most often, it is due to a number of advantages: low weight, ease of transport and installation, corrosion resistance and long service life. It is worth noting that the easiest way to crash into this type of communication is that the price of this type of work is much lower. |

Tip! To find out which pipe is laid close to your site, it is enough to apply to the water utility or simply look into the distribution well, carefully opening the lid.

How to make a tie-in

We note immediately that unauthorized accession to communications qualifies as an illegal activity. Responsibility for illegal tapping into the water supply system is a fine of 3 to 4 thousand rubles, sometimes the workers of the water utility when they find a violation expect much larger amounts to be paid, but this is illegal and the court should decide on the amount.

Regarding the specifics of the work, you must have all the necessary documents in your hands, from the project to the permission approved by the relevant organization. The works themselves differ depending on the material of the pipe.

Cast iron

As for this option, the tie-in in the cast-iron plumbing is in the following sequence:

- The branch point is cleaned of dirt, it is necessary to remove the protective coating and clean off rust.. This is very important, since corrosion after putting on the saddles can destroy the joint over time.

- Further, in the place where the hole will be made, it is recommended to remove the top hardened layer of material using an angle grinder.. This will speed up and simplify further drilling. Although some modern versions of drilling equipment are so durable that this type of work can not produce.

- The next stage is the installation of a special saddle, which is a clamping clamp for pipes. To prevent leakage, a special rubber seal is laid between the structure and the pipe; it is very important to arrange it correctly so that the holes in the collar and rubber gasket match.

- A locking valve is installed on the structure through which a special crown is inserted, with the help of which the drilling is performed. It is equipped with carbide tipped and specifically designed to work with cast iron.

- After completion of work, the valve is shut off and the device is removed from the system.. It is important to do everything as quickly and accurately as possible so that as little water as possible spills.

Tip! For drilling, you can use special high-strength devices that operate both from a mechanical drive and manually. Such compact options significantly increase the convenience of work, if drilling is carried out in the well.

Steel

Regarding this material, you can tell the following:

- Inserting water in the existing network is about the same as with cast iron pipes, but if it is possible to shut off the water supply for the duration of the work, then you can use another option, and that is what we will pay attention to.

- First of all, the surface is cleaned of dirt and treated with a grinder or a drill with a wire nozzle to remove corrosion. This is necessary in order to ensure maximum protection of the connection.

- Further, in the main highway is marked hole, which is cut as accurately as possible and accurately.

- After everything is prepared. a pipe is attached, which will serve as a tap, and is welded to the pipeline. After completion of the work, the seam is carefully inspected and, if necessary, is welded.

- Last of all, a stop valve is screwed or welded to the tap and the entire connection is treated with an anti-corrosion compound..

HDPE pipes

This option is different in that the tie-in to the existing water supply system is carried out without welding and other similar works.

Instructions for the work is as follows:

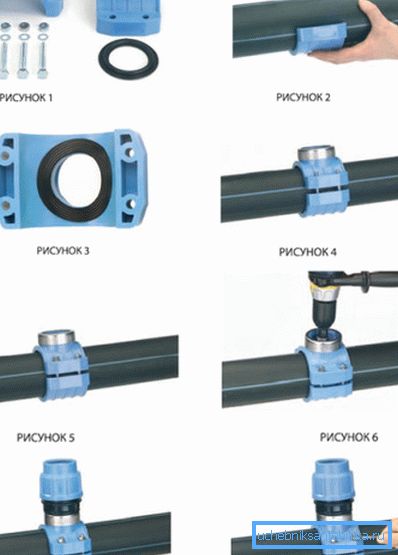

- The diameter of the water pipeline is specified and a special fitting is acquired - a clamping coupling, through which the connection will be made. In the diagram below you can see how this element is fixed, everything is done quite quickly and simply.

- After fixing the coupling, a special device for drilling holes is placed on it, which is tightly fixed on the valve. When drilling is completed, it is very important to remove the drilling unit as quickly as possible, at the same time shutting off the water so as not to flood all around.

We advise you to carefully approach the selection of the contractor and control the process, as you see, there is nothing difficult in the sidebar, and it is quite possible for any person to understand the topic.

Conclusion

Regardless of how much a tie-in to the water supply in your area costs, you will not be able to save money on this, since it is forbidden to do work on your own. But it is important to control how well the work is done, and the video in this article will tell some aspects of the right technology.