Inspection well - principles of arrangement

In any modern home sewer system is one of the main components of comfort. Fortunately, setting up a standard system with your own hands is a very real task. Apart from the pipeline, the main element of the system is a sewer manhole.

In this article we will talk about the types, purpose and principles of installation of such structures.

Types of designs

The overall system can be either narrowly targeted, designed to remove household sewage from a house, or it can be a comprehensive system that combines a sewer system with a system designed for the drainage of a plot..

They work according to a similar scheme, so in the future we will talk about the general principles of installation of structures for removing effluent.

- Nodal or connecting well - this design serves to combine several pipeline branches into a single common drain. Sewer manholes according to SNIP can unite in themselves no more than 3 sewage branches, and there should be only one outlet branch. The configuration of the tray to merge the branches should have smooth curves, made in the form of pipes.

- There are also linear wells, they are used on straight sections of the highway for inspection and maintenance of the branch. For domestic, private systems, they are rarely used, since it is not often personal possessions have such distances. The distance between objects depends on the diameter of the pipe.

| Pipe diameter limits | Distance between linear wells |

| Up to 150 mm | Within 35 m |

| 200 mm - 450 mm | Within 50 m |

| 500 mm - 600 mm | Within 75 m |

| 700 mm - 900 mm | Within 100 m |

| 1000 mm - 1400 mm | Within 150 m |

| 1500 mm - 2000 mm | Within 200 m |

| From 2000 mm and more | Within 300 m |

- Swivel structures are used to access the bend point of the pipeline. The angle of rotation may be different. The design is installed to provide free access to the inlet and outlet pipes, as the risk of congestion is quite large when cornering.

Important: when arranging the rotary structures, it is not necessary to install them at every turn. Depending on the angle of rotation, you can mount through one, but not less.

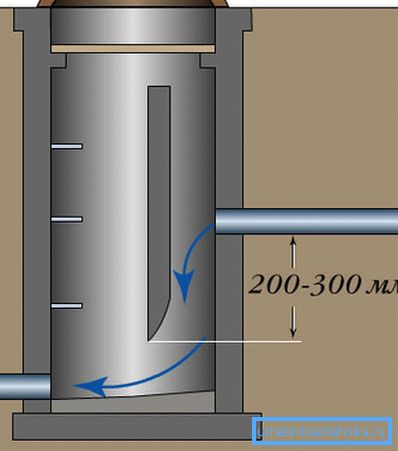

- The next type of viewing structures are the drop. They are distinguished from linear ones by the fact that their inlet and outlet openings are located at different levels. They are intended to increase or decrease the speed of movement of runoff in the system and are used to adapt to the terrain. These constructions are mounted.

- If you need to reduce the level of the incoming pipe.

- With unstable, with sudden changes, the speed of a moving stream.

- When the tubes cross the underground structures, for example, water pipes.

- If a submerged discharge into a water body is foreseen, such a structure is the last frontier of the transition.

- With a large differential, up to 3 m, between the entrance and the exit.

Important: the differential design is established only if the difference between the pipes exceeds 500 mm, and the diameter of the pipes must be more than 600 mm.

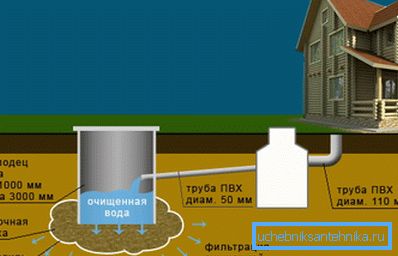

- Well for filtering or septic tank, is installed in the area standing on sandy soil or on sandy loams. For private houses, as a rule, it is equipped with a natural, multi-layer filter, but its use is limited.

- Groundwater in this area should be no closer than 1 m from the base of the structure.

- Does he have a filtration limit of 0.5 m? per day.

- On sandy soil the minimum area of contact of the base is 1 m ?, on the sandy loams 1.5 m ?.

- Storage tank - mounted in the absence of the possibility of discharge of wastewater. In fact, it is a modern, improved form of a cesspool. Drainage design option can serve as a backup tank for collecting water intended for technical needs, such as irrigation.

Subtleties of installation

The materials from which such structures are made are not very diverse, or rather the main ones are only 3.

- The first 2 have been used for a long time, they are reinforced concrete rings and bricks.

- The third type appeared relatively recently and is the brainchild of technological progress, these are various types of plastic or fiberglass. (See also the article Features plastic manhole for the well.)

Installation of reinforced concrete structures

- Before you make any kind of well, carefully and taking into account the terrain, a place is chosen for the installation of the structure. The area must be cleared of vegetation and leveled.

- Further the excavation is dug out. The dimensions of the pit should exceed the dimensions of the structure by at least 30-40 cm. For reinforced concrete and brick wells, the external clearance can reach 60 cm. Plus, you should consider the option of approaching the place of installation of special equipment.

- At the bottom of the pit, a cushion of 150-200 mm from rubble is poured and carefully tamped. In the presence of groundwater settles down the bottom waterproofing. For this, bitumen or roofing material with bitumen is used.

- Sewer manholes according to SNiP, should be installed on a monolithic concrete base. In industrial construction, a concrete slab is used, but in private construction, you can save the formwork, reinforce the foundation and pour concrete with it.

- Concrete rings are installed on the prepared concrete base. All joints, interface structures are sealed with cement-sand mortar and bitumen. Pipes mates are also coated with bitumen or bitumen mastic.

- On the outer side of the ring are waterproofed with bitumen. After installation of the top cover of the tank from the inside, the container is re-insulated. (See also the article Luke of the manhole, how to choose.)

- Ideally, a clay lock made of greasy clay, about 30 cm thick, is made along the perimeter of the entire well. But if this is not possible, then the clay lock is settled only at the joints of pipes, also 30 cm thick, and 60 cm from the top of the pipe joining point. The rest of the space is filled with soil and compacted.

- Around the neck is reinforced concrete pavement with a diameter of 1.5 m. According to the rules, the tank must undergo a leakproofness test within 24 hours. To do this, the pipelines are plugged and the system is filled with water.

Brick buildings

- The laying of a manhole from a brick is not much different from the arrangement of reinforced concrete structures. Instructions for arranging the base are almost the same, but preference is given here more to the bulk foundation, although the use of a monolithic slab will also not be a mistake.

Important: if you lay out a brick septic tank, then laying is carried out on a strip foundation. A half-meter multi-layer filter consisting of a different fraction of sand, gravel and rubble will be poured inside the structure. For better filtering, you can add a layer of shungite.

- The walls of the brick reservoir are made with a minimum thickness of 250 mm, it is 1 brick. If you make a septic tank with a transverse membrane partition, then it is laid together with the walls. Masonry is performed by alternating butched and spoon rows.

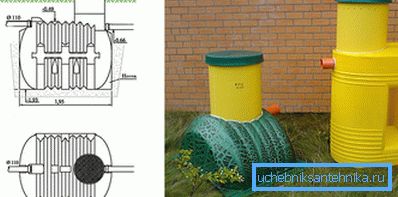

Plastic constructions

- Currently, plastic manholes are experiencing a boom in popularity. They have a sufficiently long service life - up to 50 years. Plastic is a completely environmentally friendly material. And the most important thing is that the products themselves are light. For their installation does not require special equipment. If you wish, everything can be done alone.

- The only disadvantage is the price. Although in our opinion, with a reasonable approach, this disadvantage can be minimized. So if you buy all the components of the system separately, the cost is significantly reduced. Plus, if we take into account the cost of rental of special equipment and labor, the costs are almost equal.

- If we talk about the rules of installation, plastic manholes only require the arrangement of reinforced concrete base and reinforced concrete tray. The instruction is the same as for the previous options. Plastic products do not require waterproofing or insulation, which also indicates savings. Joints are sealed with rubber gaskets.

The video in this article shows the principle of mounting plastic products.

Conclusion

Analyzing all the above, it should be noted that if you are engaged in the arrangement of the bulk system, plus do it in parallel with the construction of the house, it will be more profitable to build from concrete or brick. But on small volumes it is cheaper, faster and more reliable to use a plastic manhole.