Installation of wells for the external part of the sewer

With the construction of the outer part of the sewer network it is impossible to do without wells. They have a different purpose, size and can be made of different building materials. Installation of sewage wells on the bottom № 2-04-03-85.

Types of buildings

The regulatory document is called "Sewerage - external structures and networks" and identifies the following categories of objects.

Purpose of wells

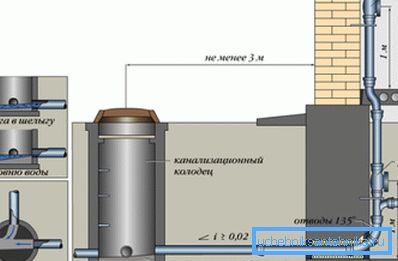

- Viewing or revision counterparts used to control the operation of the pipeline, as well as the removal of blockages. Arrangement of them is necessary if the network has a significant length. The first construction is placed at a distance of 3 m to 12 from the point where the sewer pipe leaves the building.

Note! SNiP requires you to install manholes with your own hands if the diameter of the pipes is up to 150 mm - every 35 meters, if their size is larger - after 50 meters. This is on the direct sites. In addition, such facilities are needed: at the bends of the network, when changing the cross section of pipes or slope, on the branches of the system.

- Pivoting devices mounted on the bends of the system, since they are potential areas of blockages. They can simultaneously play the role of viewing.

- Drop analogs are built when the site has a difficult terrain and the difference between the level of pipes is more than 50 m.

- Nodal wells the instruction requires to be placed at points where several branches of the network intersect.

- Accumulation and filtration devices - these are reception facilities in autonomous sewer systems. Cumulative counterparts are sealed and need periodic cleaning. Installation of a drainage well is necessary for filtering wastewater and atmospheric water into the soil.

Materials and sizes

- Stone objects for sewage are constructed of brick, monolithic or precast concrete. Filtering analogues can be built from the boot.

- Plastic analogues are made from polyvinyl chloride, polypropylene and polyethylene.

- In addition, it is possible to carry out installation of a sewer well from a combination of these materials.

According to the norms, the diameter of the facilities should be:

- if the pipeline has a cross section up to 150 mm - not less than 70 cm;

- 150/600 mm - 100 cm;

- 600/700 mm - 125 cm;

- 800/1000 mm - 150 cm;

- From 1200 mm and more - 200 cm.

Arrangement of objects

The construction of any type of sewer well should begin with preparation and excavation work - arrangement of the trench and the pit.

The order of the preparatory work

Preparatory activities include such phases.

- Site marking.

- Demolition of vegetation that interferes with work.

- Arrangement of a temporary exit or road to the site.

When arranging the pit, the procedure is as follows.

- Digging pits by hand or with the help of special equipment.

- Cleaning and tamping its bottom.

- Verification with the draft of the depth and diameter of the pit, as well as the angles of the slopes of its walls.

- If the well will be made of stone-like materials - bottom waterproofing using roofing material and bitumen mastic.

Wells from stone-like materials

If the installation of wells is carried out, then follow these steps.

- Arrangement of the base - laying the finished plate or pouring a screed, 10 cm thick, from a concrete solution of mark m-50.

- Installation of a metal-reinforced concrete tray m-100, the required form.

- Sealing with bitumen and mortar pipe ends.

- Waterproofing with bitumen mastic inside the concrete elements.

- Then you need to wait 3/4 days so that the tray is dry enough.

- Next is the installation of well rings and floor slabs, cement-sand mixture m-50.

- Then you need to rub the grout joints between the prefabricated elements of the structure.

- When it dries, the seams are insulated with bitumen.

- After this, the tray is plastered and ironed.

- Further, at the entry points of the pipes, a clay lock is made, 30 cm wide and 60 cm more high than the outer pipe diameter.

Note! Then you need to test the well. For this you need to fill it with water for 24 hours. Before that, temporary plugs are placed on the pipes. If no leakage is detected, the test is deemed to have passed.

- Then the gap between the walls of the well and the pit is filled with soil or gravel, which is then rammed.

- After that, around the perimeter of the structure neck, a pavement of concrete, 150 cm wide, is poured.

If the wells are storm, then it is equipped with a lattice hatch, additionally playing the role of catchment. When arranging the drainage system, the well can perform the function of drainage through special openings in its walls.

It should be borne in mind that there is a small difference in the design of finished concrete elements, based on their purpose.

Accepted markings of prefabricated products:

- KDK and KFK are intended for withdrawal of household sewage;

- KLK and KLV - for "stormwater";

- КДН and КДВ serve as an element of drainage systems. Installation of a fire hydrant in a well of concrete rings is possible if the building is pre-warmed.

Construction of elevation structures is more difficult than previous ones, since they have a more complex structure.

In them, besides the arrangement of the tray, it is often necessary to carry out:

- installation of the riser;

- the creation of watering;

- installation of the wall for water breaking;

- practical equipment;

- arrangement of the pit

Plastic analogues

A modern alternative to stone sewers - plastic counterparts.

- Their use greatly speeds up and simplifies construction, because no need for many stages of work.

- Their installation does not require the use of special equipment.

- They do not need waterproofing.

- The price of plastic tanks is relatively small.

Note! Some experts say about the insufficient strength of polymer wells for compressive loads. However, they do not give exact facts. Moreover, in autonomous networks there are no loads that can deform or tear plastic.

A weighty plus of such products is ease of installation, and the estimate for dismantling wells of this type is also smaller. For example, when using them, it is necessary to dig trenches that are much smaller.

Pipeline installation is also facilitated. Polymer wells are made with releases that exactly correspond to standard pipes made of asbestos cement, metal and plastic. Based on this, after their installation, the structure can be connected to the sewer system within a few minutes.

Conclusion

Before you build the external part of the sewer network, think carefully about all the points. Decide on the types of wells you need and select the material for them. Consider that the cost of installing a sewer well will be less than that of concrete (see also the article Repair of wells on your own).

When viewing the video in this article, you can get more information on the topic.