Installing the pump in the well itself

The well on the plot is an uninterrupted water source. But for its normal operation, it is necessary to install a pump in order for the water supply system to work at full capacity. Before buying such a unit, it is important to choose the right diameter. The device should pass freely through the pipes without touching the edges. The very installation of the pump in the well with their own hands is made without any difficulties, this will be discussed in the article.

Preparatory stage

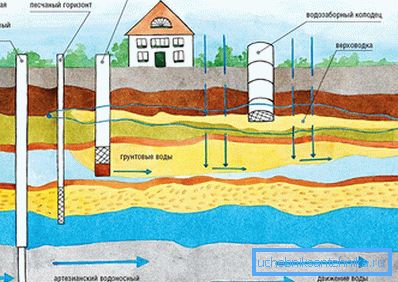

Before you start installing the pump it is worth doing some preparatory work. First determined with the parameters of the well itself. You need to know the following information:

- depth;

- diameter of the pipe used;

- water level (static and dynamic).

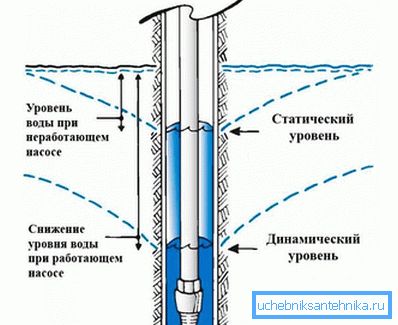

The first two parameters are understandable to all, and about the water levels should be explained. The static level indicates the pressure of the water bed itself. It can be determined after idle wells. The reservoir pressure will squeeze out water to a certain level, which is considered static.

The dynamic is the water level in the well when the pump is running. It is he who is responsible for the flow rate. When installing the equipment, it is necessary to place the pump so that it is below the dynamic level.

If you have decided on the depth of installation of the submersible pump in the well, then the next step will be the preparation of the necessary equipment and accessories. For work you will need:

- cable;

- tip;

- clips (it is better that they were made of stainless steel);

- nipple, PND-pipe, fittings;

- ball valves.

Conducting self-connection of the submersible pump, special attention should be paid to the electricity supply system. The cable that comes with the unit may not be enough for the entire depth of the well. In this case, you will need to build. This should be done carefully, just connecting the wires in color. After lengthening the cable, it is necessary to waterproof it.

Pumps for wells are very sensitive to voltage drops. The cable must be run directly from the shield, with a connection to a separate machine. It is better to additionally install a voltage regulator. In addition, you cannot turn on the pump if there is no water in the well. In this case, the unit will quickly fail.

Pump installation

Before starting the installation of the pump into the well, the evenness of the casing is checked. Any significant distortion may affect the lowering of the unit. It is also necessary to check the discrepancy between the diameter of the pipe and the pump. The instructions for each specific unit indicate the maximum values of such a discrepancy. If they are not followed, this will lead to problems when lowering the pump.

Before lowering the unit into the well, it is necessary to clean it from contamination. In addition, a partial pumping of water. It is pumped out until the moment when the water goes without impurities.

Further, the work is carried out in the following sequence:

- The pump is laid on a flat surface, and the nipple and PND of the coupling are connected to it. It is necessary to rewind the thread using flax or other suitable material.

- We unwind the HDPE pipe and connect it to the coupling. To facilitate the entry of the pump into the well, the pipe is straightened directly in front of the unit for a length of 2–3 meters. Also along the pipe unfolds electrical cable.

- Further along the pipe and the power cable the cable is unwound, which is passed through special devices at the pump. Two or three loops are made, and the end is drawn out to a distance of half a meter from the unit. Then, the elongated end is fastened to the main cable with metal clamps.

- All components of the route (cable, pipe and cable) are fastened together with plastic clamps or electrical tape. At the same time, it is not necessary to force them together strongly; there should be a small gap between the components of the “route”. Fastenings are made with a gap of 70-130 centimeters.

- Next on the casing we put on the lower part (flange) of the tip and sealing rubber ring (to facilitate the work, the flange is lubricated with silicone or other lubricant).

- Now you can lower the pump into the well. If there are difficulties (the unit rested), then it is necessary to rotate the pump smoothly with a simultaneous increase in pressure on the unit.

After the pump has reached the planned depth (it is worth remembering that the unit should be half a meter below the water level, but not reach the bottom one meter), the upper end of the cable is mounted on the crossbar. Then, the upper part of the top is put on, and it is bonded to the lower component. Now you can install additional equipment (check valve, voltage regulator, etc.) and you can use the autonomous water supply system.

Video

See how the selection, piping and installation of the pump in the well: