Lid on the well: the right choice

The well for drinking water is a place where it is necessary to follow certain environmental safety rules so that the source of the liquid does not become a zone of infection and disease. That is why quite often such constructions are enclosed by protective systems and installed at a considerable distance from cesspools and waste dumps.

Special attention is given to the cover on the well, because they are the very first and main obstacle between the environment and the internal volume of the structure.

General concepts

First we need to say that there are a huge number of different types of wells that perform their own functions that are not similar to each other. At the same time, well covers also have their specific purpose and additional structural solutions inherent in a particular model.

Purpose

- Some suggest that the only purpose of such products is to protect against accidental access to the inside of the structure. At the same time, the density of the hatch connection must be such as to ensure the greatest possible tightness.

- Such a statement can be considered true only when it refers to the lid on the sewer. This is due to the fact that it is necessary not only to organize controlled access, but also to create an obstacle to the exit of odors to the outside.

- Some water wells need to be ventilated, which means it’s worth creating a special ventilation hole in their lid..

- Special attention should be paid to specialized systems, which can be additionally equipped with inlet and exhaust valves, special shut-off systems or other devices.

- It is worth mentioning that most of these products must have a certain strength. Generic safety instructions advise that an installed cover on the floor can withstand the weight of a passenger car when hit. If the installation is made on a special design, located on an elevation, it is sufficient to reduce the load to 150-200 kg over the entire area of the product.

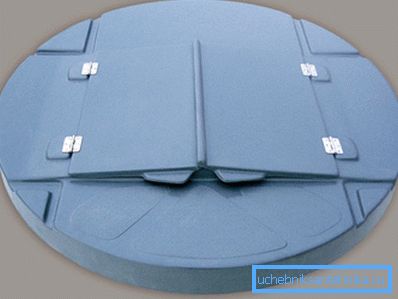

- When an independent installation of such systems is made, it is immediately necessary to clarify the method of attaching the hatch to the main structure. The fact is that each individual model has its own unique design and is fixed in its own way, depending on the type of material from which the well itself is created. This is especially important when installing plastic parts that imply an individual installation method.

Tip! Professional masters recommend not to spend a lot of money on additional options or properties, but to select the device in accordance with the technical conditions of the site.

Manufacturing material

- The simplest covers for these designs were made of wood. They can easily be created with your own hands, saving a lot of money. However, such parts are strongly affected by dampness.

- As a result, wooden covers often cause mold or mildew. In this case, this problem can be eliminated by treating the surface with an appropriate protective composition.

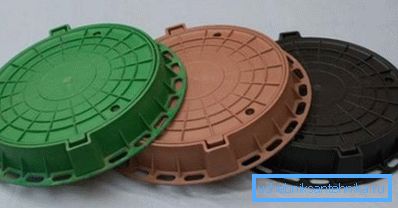

- Separate attention deserve the system of polymeric materials. They perfectly cope with any tasks and have a good appearance. Also, such products have a wide variety of models and shapes, which allows you to choose the best option for a particular well.

- When it comes to talking about covers made of cast iron, the first thing that comes to mind is quite a high price. This is due to the large weight and expensive cost of the material itself. However, most of these hatches are often left unattended, which leads to their plunder.

- It should be noted that such elements of the well can be called the most durable, since they can withstand heavy loads. At the same time, cast iron has excellent performance in a wet environment and practically does not corrode.

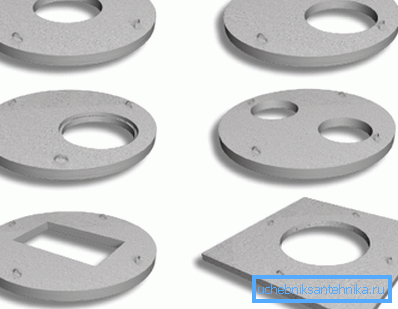

- Recently began to make and reinforced concrete covers for wells. However, they are not very practical and have too much weight. These products should not be confused with the floor slabs in which holes are made to install the hatches. They have a completely different purpose and are used to create the well itself, or rather its upper part.

Tip! Professional masters recommend to stop the choice on polymeric products. Especially if one of them created the whole system of the well. This combination will allow to achieve maximum results and quality at relatively low costs.

Conclusion

After viewing the video in this article, you can get more detailed information about what kind of covers for wells, and learn about their various configurations and models. Also on the basis of the text that is presented above, it can be concluded that in each particular case it is worthwhile to apply a certain type of this device (also learn how to draw water from the well into the house).