Log cabin for the well: options for arrangement

Since ancient times, the well has been considered one of the most reliable sources of water. The most common are mine type wells. The most important part of the arrangement of this type of structure is a well-frame house. Now we will try to figure out what it is and how difficult it is to make a blockhouse on the well with our own hands.

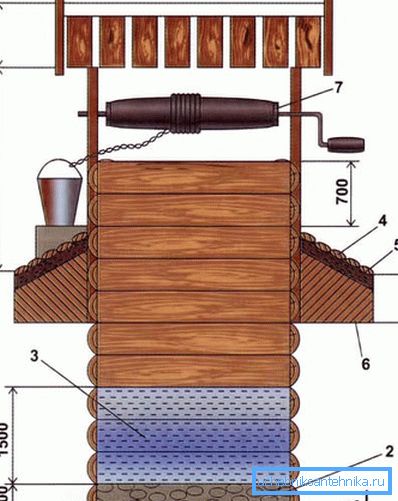

Many ordinary people mistakenly believe that the felling is the same house that covers the underground part of the trunk and with which you can raise a bucket of water to the surface. But this opinion is not entirely correct, the ground part is only a design head.

The concept of a well-built log house includes the entire trunk finish from the bottom to the ground part. Which protects the barrel from collapse and ingress of dirt from the groundwater into it.

Half a century ago, the fellings of wells, for the most part, were made of wood. Now available more affordable and durable concrete structures or stone.

Wooden houses

As mentioned earlier, in the relatively recent past this material was the most common. At present, there are gourmets who are ready to revive the technologies of the past in order to equip themselves with an environmentally friendly original log house on a well, stylized antique, although the price of such a design will be quite high.

Wood selection

- True royal wood here is oak. Oak well log buildings can last up to 50 years without repair. But there is a small nuance, freshly cut wood is not suitable for work. Oak should be bogged down, as there are a lot of tannins in it, and they will affect the taste and quality of water.

- Instructions for striking oak are extremely simple and accessible to everyone, but the process takes time, from 1 year to 3 years. Initially, even logs are taken without large knots and are cleared of bark. After that, experienced craftsmen prefer to cut the logs and collect the logging blanks from logs or timber.

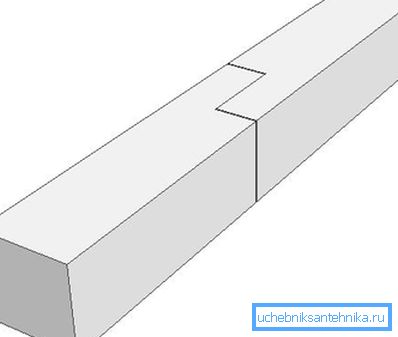

- It is considered the most accessible connection in the half-tree, but you can dock it “in the paw”. The trunk sections are 2 m in height, about 200 mm in cross section of logs. After that, the logs are numbered, the whole structure will be disassembled and immersed in water, preferably in flowing, for a period of 1 to 3 years. Further, the logs are formed under a canopy in a draft and dried during the summer.

- Beech, elm or ash are also used for construction. Unlike oak, they do not need to be starved, they do not change the taste of water. In the underwater part they can serve for a long time, but in the air these rocks are subject to rotting. Because of this feature, the wood of the trunk is combined. Beech elm or ash submerged in water, the rest of the trunk is collected from oak, larch or pine.

- Pine, larch or cedar are universal tree species for wells. They are suitable for both surface and underwater parts of the trunk. The only negative here is that the barrel will serve about 30 years,

- Willow, spruce or birch rarely go to the log houses of wells, since they are prone to rotting and such a trunk will stand about 5-7 years. The wood of these species may be suitable, perhaps, for the land part of the log house, the tip.

Principles of installation

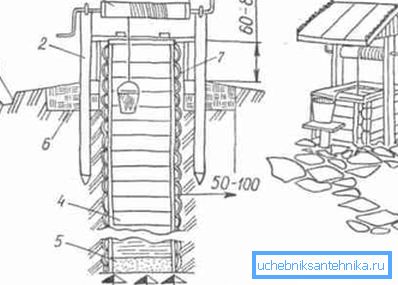

- This method is the simplest and most acceptable for the arrangement of their own hands. The first stage in the organization of the well, of course, is the digging of the trunk. If there is a soft ground in the area, then as it deepens, the walls of the mine should be strengthened with wooden formwork so as not to collapse. The size of the trunk should be 30-40 cm larger than the outer wall of the log house.

- After reaching the design depth, the accumulated water must be pumped out. As a rule, this is done in buckets, since the price of a special deep well pump capable of pumping out dirty water is quite high.

- Before making the foundation of the future structure, the bottom of the mine is leveled. If the soil at the bottom is soft and unstable, flagstones are laid under the crown, these are large stones serving as the foundation. Stones are stacked on the level, so that the subsequent laying is not twisted.

- After installing 2 - 3 first crowns, the lower crown should be prikopat, because at the initial level, the logs can float when filled with water.

- After that, subsequent levels are gradually mounted. The crowns should be connected as tightly as possible; for this, each crown, after installation, is knocked over the perimeter by a small badger (wooden hammer). It is impossible to beat directly on a log, for laying in such a way wooden laying is used.

- At the end of the installation of each crown, the frame should be checked for horizontal position, using a level and verticality using a plumb line.

- After installation of level 6, work is suspended to organize a natural filter at the bottom of the well. The first layer is covered with large crushed stone 100 mm from the bottom. Next, a layer of small or medium gravel is poured on 50 mm. Then a cushion is made consisting of river sand 200 mm thick. All materials, before backfilling, should be thoroughly washed.

- In the case when water enters the well not only from the bottom, but also from the side, holes are made in the logs located under water. The outer side of the structure is filled with gravel or rubble, at least 250 - 350 mm thick. The side cushion should rise 100 mm above the aquifer.

- Log cabin to the well in the shaft should be fixed. Fixation is carried out with the help of collateral crowns. For arranging such levels, longer logs are taken, protruding 50 cm beyond the limits of the structure. A tunnel is made for mounting in the wall of the trunk: if the ground is soft, then limestone is laid under the pledges and the pledges are wedged.

- The entire barrel must be completely sealed. To do this, each level, around the perimeter and, especially in the slots, is smeared with greasy clay. But to completely seal the barrel, it is better to build a clay castle. Instructions for arranging are simple: fat clay is poured into the space between the walls of the structure and the walls of the trunk, which subsequently is well compacted.

- At the bottom of the barrel, a layer of clay of 150–200 mm is enough, but the closer to the surface, the thicker the lock should be up to 350–400 mm. Thanks to such a shutter, your well log house will be reliably protected from ingress of groundwater.

It is important: to seal the connections with hemp or tow, as well as paint the walls of the mine or impregnate the wood, it is strongly not recommended to use any antiseptic. Since this can adversely affect the quality of water.

- When the entire shaft of the shaft is laid out, the outer strapping is made of larger-diameter mortgage logs. They will serve as the basis for the construction of a wooden superstructure. Arrangement of the site around the mine can be done in different ways, here already as it suits you best. The blind area is made in diameter of 2 m from the trunk.

- If you are building a 100% environmentally friendly antiquated structure, then you need to remove the top layer of soil 20-30 cm and build a mound of fat clay, a clay castle around the mine. The blind area is made under the slope of the mine, the guides of the logs are laid on it, and the flooring is sewn up from the boards.

- But it will be easier, safer and more durable to make a pillow of sand with gravel and pour reinforced concrete under the slope. You can simply lay around the concrete or stone slabs.

- Since it is completely problematic to change the log house in the well, often the owners prefer fragmentary repair. In other words, only logs that have become worthless change. And although the price of such repairs is high, it is cheaper than changing the entire structure.

Concrete structures

- More affordable, easy to install, and therefore more popular, are log cabins of wells of reinforced concrete components, as a rule, concrete rings are used.

- For old trunks with wooden strapping, replacing a log in a well with reinforced concrete is the best option. Installation instructions are much simpler here than in the first wooden version.

- The beginning of the installation here repeats the first option. Initially, the well is drained and leveled the bottom of the mine. The first ring, which serves as the base for the entire trunk, should be thicker than the rest by 50 mm.

- The lower edge of the ring should be tapered, necessary for good penetration. If a cone is not provided, a metal knife consisting of a strip and welded metal pins is made.

- Before installing the next ring, a sealing layer of cement-sand mortar from waterproof cement is applied along the perimeter of the lower segment. After joining the segments, the gap between them is additionally smeared with a solution and fixed with waterproof metal metal clips. You can fill them with both external and internal.

- Sometimes, from the inside of the trunk, a ladder of the same metal brackets is packed, it is intended for repairs. But the need to install such a ladder is solved individually.

- As in the first case, if the flow of water is not only from the bottom, but also from the side. At the level of the aquifer, holes are made, gravel is poured on the outside, 100 mm above the aquifer. Plus, at the bottom of the well, a natural filter falls asleep.

- As the rings are installed, a hydraulic lock is made along the outer perimeter. You can use the clay castle, the price for it will be much less. But if the trunk stands on unstable formations, we recommend reinforcing the outer perimeter and filling it with waterproof concrete.

- The fact is that the clay lock will not be able to keep the movement of the layers, as a result of which the rings may move and the tightness of the barrel will be broken. And the reinforced concrete shirt, will be reliable protection for a trunk.

- Having reached the surface of the earth, around the trunk, an inclined blind area is made of concrete. The minimum blind area is 1 m.

Important: there are also flat reinforced concrete sections intended for arranging trunks. They provide for the connection "in the paw", mounted such sections on the principle of a wooden log house, but the installation is longer and more laborious in comparison with rings.

The video in this article shows the process of bookmarking rings.

Conclusion

In conclusion, it should be noted that before using the new well, it is recommended to pump it out several times to remove the first dirty water. And when the water becomes crystal clear, we advise you, first of all, take it for analysis in the SES. Sometimes the cleaning of the well can last up to 1 year.