Manhole manhole: features of the device and the main types

The hatches of manholes, although not complex and costly, still perform a rather important function. They close the lumen of the well, preventing penetration of precipitation and debris into the inside, and at the same time protect people and pets from falling into a hole.

Naturally, it is necessary to choose the hatches depending on what task they will carry out and what loads you plan to expose. And since modern industry produces these parts in an extensive range, this article will help to understand all the abundance of options available.

Purpose and Diversity

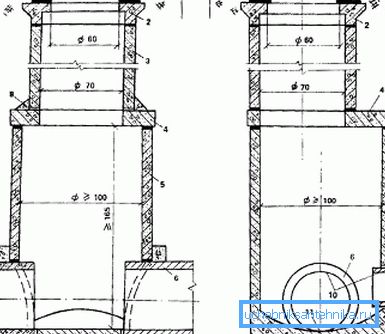

Inspection Well Design

For the most efficient operation of plumbing, sewage and other communication systems, access to underground pipes and wires is necessary. And to ensure this access all along the strip, the so-called inspection wells — vertical shafts — are installed, down which you can assess the condition, adjust or repair the communication.

A typical well consists of the following elements:

- Workroom. Located in the lower part, it includes pipes and cables, as well as a camera in which a person may be present during work. A full-fledged workroom is equipped only with viewing wells of major highways, while on small networks (for example, shallow sewage systems of a private house), in order to save money, they try to do without them.

- A shaft is a vertical channel connecting communications or a workroom to a surface. With a great depth (from 2 m and more) it can be completed with a stationary ladder.

- Manhole - provides access to the inside of the well. In most cases, consists of two parts: a stationary neck, fixedly mounted in the upper part of the shaft, and a removable cover.

- In some wells, the neck has a more complex structure and is equipped with two covers - protective and shut-off. The locking device has a relatively small mass, however, it has a high mechanical strength and is equipped with a sophisticated lock. Most often, steel locking caps are installed on the wells of cable networks to prevent theft of non-ferrous metals. (See also the article Cover for the well: how to install.)

Manhole requirements

The reliability of the whole system depends on the design of the manhole cover.

As a rule, this element is characterized by:

- High mechanical strength to withstand intense pedestrian and traffic loads. To avoid breakage, these parts are made of cast iron, polymers, reinforced concrete, etc.

- Significant mass, almost excluding spontaneous opening.

Note! Models characterized by low weight are necessarily equipped with complex swivel locks.

- Smooth textured surface that ensures the adhesion of the soles of shoes and tires with the hatch cover. Smooth hatches are almost never done, with the exception of models that are designed for flush mounting under a layer of coating.

- High degree of tightness to protect the contents of the well from moisture. Some lids make special openings for opening, but this is allowed only when equipping water supply and sewage systems.

- The shape of the lid is usually even or convex. The use of concave parts is irrational, since in this case the hatch becomes a place of accumulation of rainwater, and in winter - snow and ice.

Features of the locking mechanism

In most cases, the locking connection of the lid with the neck is not difficult. Its main task is to prevent spontaneous opening under the pressure of a foot or wheel, and also to fix the lid in the neck and prevent it from moving.

As a rule, such compounds are of two types:

- Cast-iron and polymer-sand parts are made with side projections, which, when laid, fit into the corresponding grooves on the neck.

- Plastic products can have a threaded connection and be additionally equipped with folding handles.

Note! Details made of reinforced concrete often have the shape of a strongly truncated cone and function according to the plug principle, without any fixings.

However, hatches that are installed on wells with telephone wires or electric cables can also be equipped with a locking mechanism:

- The most common locks are flag-type, in which steel protrusions form a hook between the neck and the lid.

- Less commonly used threaded connection with a bolt that has a secret.

- However, the most reliable is the expansion mechanism, which locks the lid in the neck when locked.

Other designs may also be used abroad, and you can see some of them in photos in our article.

Hatches classification

In order for everyone to have the opportunity to choose a hatch according to the needs of a particular situation, several options were developed for classifying these parts. The most popular is the classification by load class.

According to this document, hatches are divided into:

- Lightweight (full-sized and small-sized) - can be used in pedestrian areas, green spaces and private households.

- Mediums - are used in parking lots and sidewalks.

- Heavy - are installed on the carriageways with medium and high traffic intensity.

- Heavy trunk - used on intercity highways with high traffic.

- Super heavy - mounted in warehouses, airfields, ports, etc.

In addition, manholes manholes are divided into several categories depending on the material of manufacture. It is this classification that we will devote the following sections of the article.

Cast iron construction

Specification according to GOST

The most common today are cast iron structures. GOST on cast-iron manholes for manholes provides for compliance with the following requirements:

- Constructions that comply with this standard should be suitable for one of four sizes: light, heavy, heavy trunk and repair. The mass of products must correspond to their type.

- Each cap must be labeled for its intended purpose. The main marking symbols are: B - water supply systems, K - sewer networks, D - fire hydrants, D - systems for rainwater flow.

- The surface of the cover should be ribbed. The ribs can be either wavy or tangential in shape (see the drawings and diagrams for the article).

- The necks are made by injection molding from cast iron of СЧ15 brand and above. For the manufacture of covers used raw materials not lower than SCh45.

Note! If the design provides for the equipment of a rubber gasket, then according to GOST 3634 - 99 its hardness cannot be less than 40 units.

Advantages and disadvantages

The advantages of cast iron hatches are obvious:

- The material can withstand loads of up to 75-80 tons.

- At observance of the production technology the durability of a product is guaranteed.

- Temperature deformations of massive metal parts are minimal.

Cons are also present:

- High price.

- Considerable weight and as a result - difficulties in moving the cover.

- The possibility of arcing in contact with the metal.

- And most importantly, these hatches systematically steal and pass into the smelter.

Polymer-sand products

Production

As an alternative to cast-iron cast structures today it is proposed to use hatches made of polymer-sand material.

These products are manufactured according to the following scheme:

- Polymer raw materials of high strength are heated to temperatures above 3000 With, achieving maximum turnover.

- In the molten polymer lead carefully sifted quartz sand, as well as coloring and stabilizing additives.

- Depending on the pigment used, the product can be green, red, orange - in general, it can be made both invisible against the background of the coating, and contrasted to attract attention.

- The resulting mixture is stirred until a homogeneous mass.

- Metal reinforcement is laid in special shapes. The thickness of the reinforcing bars largely determines the strength of the product.

Note! The presence of reinforcement facilitates the search for hatches hidden under snow and ice. To find a manhole on the icy road is enough to use the simplest metal detector.

- The polymer-sand mixture is poured into the reinforced mold, after which the part is sent to the pressing section with further drying.

- The finished product is removed and subjected to finishing processing - leveling the edges, removing burr, etc.

Depending on the thickness of the polymer and the diameter of the reinforcing rod, polymer-sand hatches are divided into several categories:

- Lightweight - weighs no more than 45 kg, can withstand loads of up to 3 tons. The optimum choice for the majority of personal plots and private possession.

- Medium - have almost the same mass, but due to the use of thicker reinforcement can withstand loads up to 6 tons. Can fit on roads with low traffic.

- Heavy - weigh more than half a centner, "hold" up to 15 tons. They are almost a full-fledged replacement for cast iron on the roads.

Advantages and disadvantages

This type of product has several advantages:

- Bearing capacity is quite sufficient for use in most situations.

- Due to the relatively small mass of the hatches are easily mounted by hand.

- Sophisticated design makes it easier to open and close the hatch.

- Unlike metal products, the lid and the neck do not “stick” to each other, even in hard frost.

Note! Observance of the dimensional grid at the pressing stage allows to achieve maximum tightness of the manhole.

- The material (polymer-sand composite with additives) is not subject to rotting and corrosion, and is not deformed even with a sharp change in temperature.

- The hatch turns out quite frost-resistant, as the mixture does not lose strength at lower temperatures.

- The cost of products is also lower than that of cast iron. This is explained by the simplicity of the technological process: the production does not need a furnace capable of smelting metal.

However, the main plus is the lack of interest on the part of intruders. To steal such products is meaningless, because they contain the minimum amount of metal. And it is very difficult to extract it from a polymeric monolith.

As for the minuses, they also take place:

- For roads with extreme loads, it is better to choose cast iron. In any case, mass production of polymer hatches with a bearing capacity of more than 50 tons has not been realized to date.

- The durability of the filled polymer is also inferior to metal. The instruction attached to most of these products guarantees service for 20 years. As a rule, in reality, this period is much higher, but still after 40 years hatches will have to be changed. As for cast iron products, today in some places those that were still cast during the “NEP” serve perfectly.

Other varieties

Naturally, the list of used parts is not limited to these two varieties.

The most popular, in addition to the cast-iron and polymer-sand, also include plastic and reinforced concrete hatches:

- Plastic constructions are made from PVC based technopolymers. The most common method is injection molding.

- The advantages of plastic constructions of manhole covers include low mass and relatively low cost.

- At the same time, substantial elasticity, as well as high brittleness at low temperatures, limits the use of these products. Most often they are used in garden plots, and they are installed where practically no one walks.

- Reinforced concrete structures with steel reinforcement are also used quite often. They have a good margin of safety, because they can be installed on construction sites and other similar objects.

- To extract the part from the neck, a steel bracket is used, which is welded to the reinforcement cage at the production stage.

- The key disadvantages of concrete products - an unaesthetic appearance and difficulty in installing flush with the neck. In most cases, the concrete "cork" is used as a temporary measure, for example, to block the hole in the well when stealing a regular cast-iron hatch.

Conclusion

The hatch of the polymer sand manholes, along with plastic and cast iron products, can be used on your site. (See also the article Plastic lid for the well: how to choose.) It is important to choose a model that will best fit the tasks assigned to it.

But products made of reinforced concrete should be used only at the construction stage: they look not very beautiful, and you will regularly stumble over the protruding edge. A more detailed overview of the described details, you can look at the video in this article.