Passage valve - flow master

Every minute and every day huge volumes of various substances - water and oil products, oils and gases move along the pipelines. One of the elements of valves that are responsible for the movement of traffic flows is a ball valve.

Its functions include stop and start, regulation, and due to the design of some species and mixing transported media.

The main thing about the crane

The regulating valve through passage is intended for constipation and start-up of the medium and regulation of the flow rate. The ball valve is distinguished from a series of passages with minimal hydraulic losses, which are achieved thanks to the ball valve. It is this form of locking device used in gas pipelines.

There are a number of advantages that are:

- in the simple structure of the reinforcement assembly;

- high degree of tightness;

- resistance to aggressive media;

- simple management;

- compactness;

- clearly limited turning radius of the handle;

- multi-stream mixing capabilities;

- universal throughput - from liquid to viscous media, as well as media with impurities (sludge, pulp).

For ball valves, brass, steel, cast iron, polypropylene, polyethylene, ceramics and aluminum are mainly used. Nests are made of graphite, plastic, rubber and various metals.

Ball Valve Design

The ball valve through passage is a reinforcement with a quarter stop rotary mechanism. Its main task is to completely open or overlap, but not to regulate the strength of the traffic flow. In case of incomplete opening of the constipation in high-pressure pipes, turbulence may form, which gradually leads to loss of tightness.

The principle of operation of the locking assembly is simple - turning the handle counterclockwise 90 ° means that the valve is fully open when the lever is parallel to the pipe, and closed - in a position perpendicular to it.

The reinforcement assembly is:

- spherical lock having a through hole;

- 2 saddles holding the sphere;

- spindle;

- housing, in which the above elements are located;

- control handle connecting to the spindle.

The body of the crane can be monolithic or collapsible. The dismountable design is unsuitable for maintenance and repair, so its price is low. The folding option can be repaired, which allows it to be operated for a very long time.

The small diameter of the hole in the ball constipation does not require much effort to control it. Large aperture diameters may require the use of a longer lever or an automatic drive unit.

Note! A long handle is not always appropriate, especially if the crane is installed in cramped conditions. Other pipes may interfere with turning it; installation of an electric drive on a crane may be the way out.

Spheres of application

Ball valves today are indispensable in the chemical, oil and gas industry, utilities, providing homes with gas and heat. In the apartments, such devices are placed on the supply pipes to the equipment.

Use of knots happens in strict accordance with their class of tightness.

The ordering of this process is regulated by GOST 24856-81, according to which the body of the crane has a certain color in accordance with its application:

- water traffic is indicated in blue;

- gas yellow;

- petroleum and petroleum products - black.

Classification of locking devices

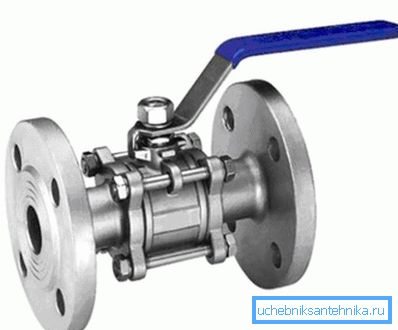

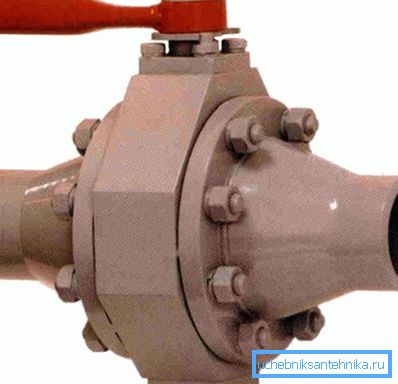

According to the method of connection to the pipeline, ball locking devices have the following types:

- flange - are collapsible and cast, withstand high pressure and are therefore welcome in highways with a cross-sectional diameter of more than 46 mm of the gas industry and oil refineries;

- coupling - successfully used in pipelines with a cross section of up to 45 mm, in communal heating, gas and water systems;

- choke - most often used in food and chemical industries, the main advantage is repairability and reusable assembly / disassembly;

- welded - are characteristic for use in the construction field, installed once, the price is relatively low;

- combined - mounting options are possible, can be controlled, being deep in the earth, thanks to the extended axis of the valve.

In the direction of traffic flow and the number of connections:

- checkpoints - the inlet / outlet are on the same axis, mounted on level sections of pipes of different diameters;

- angular - the axis of the holes are perpendicular to each other, mainly located at the points of connection to household appliances, for example, to the battery;

- three-way (mixers);

- multi-pass.

Depending on the bandwidth share:

- full bore - up to 100%;

- standard - up to 50%;

- Non-full 70–80% flow.

The diameter of the hole in the gate of the full bore ball valve coincides with the internal diameter of the pipeline, and therefore the hydraulic resistance is minimized, as is the pressure loss. Such fittings are well suited for liquids.

The hole in the ball of the non-full-pass assembly, on the contrary, is smaller and may be cone-shaped (one or two symmetrical passes), and therefore there is a greater hydraulic resistance. The small diameter “facilitates” such cranes, they are durable, since they let in small flows and the load on the ball decreases, compare favorably in price.

General installation rules

You should not remind that the operational term and quality of work depends on competent installation of a reinforcing unit.

General installation instructions include:

- The final choice of installation site and the provision of free access to it for installation and repair work in the future.

- The need to check the compliance of parameters such as the diameter of the valve and pipe, the capacity of the valve and its compatibility with the working conditions (type of medium, maximum pressure in the pipeline and temperature).

- To know the direction of the transported flow, which is additionally shown by the inlet / outlet arrows on the device body.

- Matching location and type of thread.

- The use of sealing tape in the threaded elements, which must be wound with a certain effort to guarantee sealing.

Note! In order to correctly reel the FUM tape with your own hands, you must see an open external thread from the side of the point of attachment in front of you. Wrap the tape in the clockwise direction.

- When flanged, their construction on the crane and pipe must be the same.

Summarizing

Valves corresponding to the technical characteristics of the pipeline and the medium to be passed through will function qualitatively and for a long time. The advantages of the shutter, simple and at the same time ideal shape, are successfully used in both the industrial and residential sectors.

The video in this article shows one of the options for using a tap valve (in this example, for organizing drip irrigation).