Plastic caisson for the well - the main advantages

The issue of uninterrupted water supply to a private house has long been resolved. To do this, it is enough to drill a well and install the appropriate equipment for operation. But there remains a small nuance, in winter the water may freeze.

Of course, at the depth of the water does not freeze, the problem occurs when water is supplied to the surface, into the pipe distribution. To solve this problem and mounted the caisson. We will talk about what it is, what they are and how to install them by hand.

What it is

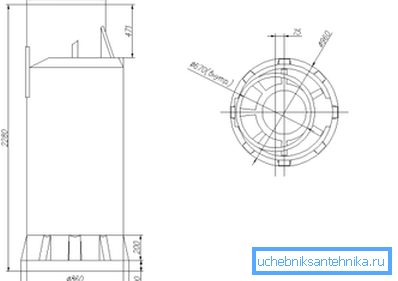

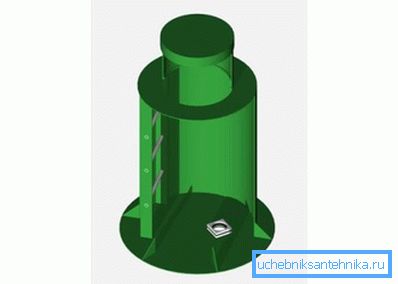

The product itself is a cylindrical or square container, in which the casing of a well throat enters and seals from below. The tank is recessed into the ground to a depth of 2 m. The dimensions can be completely different, the most common size, it is a round cylinder with a diameter of 1 m and a height of 1.5 - 2 m.

But there are products with a diameter of up to 2.5 m. It all depends on the functional fullness, in other words, what is planned to be installed there. In essence, a caisson is the technical name of any well. The caisson is a sewer well, a tie well or, as in our case, a well for arranging a well.

What they are

The choice of material here is not great, more recently, these structures were made only of metal or reinforced concrete, but now they are worthy of competition plastic.

- Reinforced concrete wells, used for a long time, they can be called the oldest representatives of this type of construction. It can also be attributed, and structures made of brick or stone. They have several disadvantages.

- Reinforced concrete rings are heavy, which leads to the use of special equipment for the delivery and installation of the well.

- Careful sealing of the seams is required; these seams will subsequently be a weak point for the penetration of groundwater.

- Although the price of reinforced concrete structures is not great, but they require the arrangement of expensive waterproofing.

- Steel structures are much lighter than reinforced concrete, but special equipment is also required for their installation. They are welded from sheet steel with a thickness of 4 mm, thanks to which they have good tightness and can be of arbitrary shape. But they are prone to corrosion, plus, in addition to good waterproofing and anti-corrosion coatings, they need to be equipped with thermal insulation.

- Plastic caissons for wells at this time are the best option. They can be made of polyethylene, polypropylene, fiberglass or unplasticized polyvinyl chloride. The characteristics of these types of plastic are similar, so when choosing, you should focus on the operating conditions of your particular well. Next, we will talk about the plastic version of structures.

What are they good for and what are the disadvantages

- The capacity of plastic is not subject to corrosion, it does not rot, the properties of the material allow to operate the product for several decades, without loss of technical characteristics.

- When installing the caisson for plastic wells does not require additional waterproofing.

- As you know, plastic is a fairly light material, so products from it in most cases do not require the involvement of expensive special equipment. As a rule, 2 to 3 adult men are enough to install and assemble the structure.

- Thanks to the use of modern technology, in particular rotational molding, the product goes solid, that is, it does not have seams. Which greatly reduces the risk of damage.

- Structural stiffness may vary depending on wall thickness. Thickness ranges from 10 to 40 mm. Plus, most products are equipped with ribs of different configurations.

- The material itself has a rather low thermal conductivity. Due to this capacity does not need to arrange additional thermal insulation.

- And most importantly, even the most expensive types of plastic structures, the price will be significantly lower than that of competitors made of concrete or steel. This largely determines the high popularity of this type of caissons.

- The caisson for a plastic well has, perhaps, the only significant drawback: when groundwater is close to the surface, it can deform from lateral pressure or it can be squeezed out. But this is easily corrected, it is enough to pour concrete around the tank with a thickness of 100 mm. Some structures have cavities in the bottom for concrete, which prevents their extrusion from the ground.

Important: we do not advise you to use plastic constructions if there is a quicksand at the well site. Too great a risk of deformation and destruction.

Getting Started

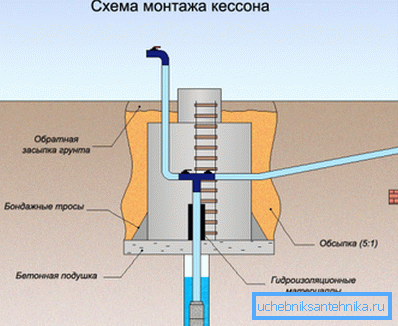

- Initially, a hole should be dug around the well. The dimensions of the pit should exceed the size of the structure by 20 - 30 cm. And do not forget to go deeper, in order to build a reliable basis for a caisson. The minimum height of the structure neck above ground is 100 mm. But it can vary depending on the amount of precipitation in your area.

- Next, proceed to the arrangement of the base. The instruction here is reminiscent of the process of laying the foundation. A layer of sand is poured onto the leveled soil; fine gravel is poured with a second layer. After that, many experts advise to increase the rigidity lay a reinforced metal frame. Further, the base is poured with concrete, and work is suspended until the concrete has set.

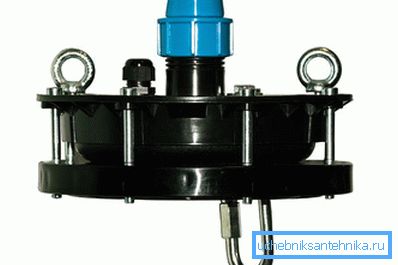

Important: if the installation of a hydroaccumulator or other necessary equipment is planned in the well, it is better to place the hole under the casing not in the center, but closer to the wall.

- Casing pipe, it is not necessary to cut off on the level of the soil, this question is not fundamental. Moreover, it is much more convenient to put on the caisson and subsequently install the tip if the pipe rises by about 1 m.

- As mentioned earlier, the plastic material is lightweight and the design will be convenient to mount using bars. The casing should be placed on the casing carefully, controlling the perpendicular between the pipe and the base of the well.

- When a plastic well is installed, it should be securely attached to the base, it can be done differently, in some designs, cavities are already provided at the base for weighting with concrete. If a hydroaccumulator is mounted inside, weighting is not needed. You can simply tie to a concrete base.

- Further, the remaining space is filled with soil, but this should be done only on stable and dry soils. In the case when there is a risk of close groundwater flow, we advise you to fill the remaining space with concrete. For reliability, the concrete layer is better, as well as the base, reinforced. The cost will not increase significantly, and the effect of reinforcement will be huge.

- Before pouring concrete, do not forget to mount the workpiece to remove the piping and electrical cable. After pouring the concrete, wait until it hardens, and only then proceed to the installation inside the construction of the pumping equipment and the arrangement of the piping. (See also the article Cementing Well Features.)

Important: if the well is bordered by a warm house or is in the basement of the house, then you can do without arranging the caisson, but then you have to endure additional noise from running pumps.

Conclusion

As you can see, plastic caissons for wells are self-assembled easily enough. Their price is not high, but the effect is significant. You not only protect the system from the cold, but also forget about the annoying noise of the pumps. (See also the article Replacing the pump in the well: design features.)

On the video in this article you can watch the details of the installation.