Plastic casing for wells - their features and installation

Not so long ago, asbestos-cement and steel pipes were used for water extraction while drilling wells. However, nowadays developers are increasingly preferring PVC casing, since it greatly exceeds the existing analogues with its operational properties.

Next, we will look at how PVC pipes are better than products made from another material, and we will also understand how the casing is being made with plastic pipes.

General information

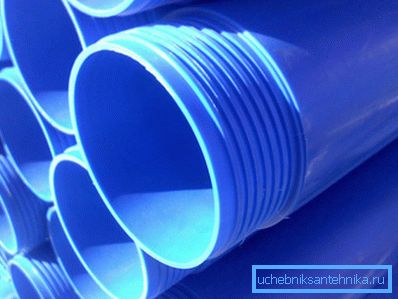

Usually such pipes are made of dense polyvinyl chloride with a characteristic blue color. Most often they are supplied with threads - on the one hand internal thread, and on the other - external. (See also the article Water supply system from a well and a well: features of arrangement.)

Make them of different diameter, which is in the range from 80 to 225 mm. Production is governed by GOST TU2248-001-84300500-2009. The wall thickness varies from 7 to 20 mm and depends on the depth of the well - the deeper it is, the more thick the walls of the product should be.

Merits

As already mentioned above, plastic pipes have excellent performance, in particular, the following points can be distinguished:

- Durability - Strengthening the walls with plastic allows you to operate the system for a long time. The claimed lifetime is 50 years.

- Plastic product is not subject to corrosion, so that over time does not deteriorate the quality of produced water.

- Low price compared to alternatives.

- High chemical resistance, thanks to which even low-concentrated acids can be transported.

- Plastic is completely inert to contact with water, so that the product is considered hygienic.

- Due to the reduced diameter compared to steel pipes, the drilling speed is increased.

- Low weight and good strength.

- Low cost of installation work.

disadvantages

There are not many flaws in the product, but they also exist:

- Lower durability, than at alternative options;

- Sensitivity to mechanical stress.

As a result of these shortcomings, the product can only be used for wells whose depth does not exceed 50-60 meters, provided that there are no saturated upper aquifers and moving layers of soil (fluids) throughout the entire depth of drilling. In addition, it is unacceptable to use a plastic pipe when drilling in two columns. (See also the article Replacing the pump in the well with your own hands.)

How to choose a pipe diameter

The determining factor in choosing the diameter is the performance of the system. The larger the diameter of the product, the greater the possible flow of water. Therefore, before making a choice, it is necessary to determine the maximum (peak) flow..

The maximum water flow should meet the needs of all water-consuming appliances, provided they work simultaneously. For example, one open water tap consumes about 0.7 cubic meters of water per hour.

If there are several taps, a washing machine and a bathroom in the house, the consumption can be about 3 cubic meters. In a large house, this figure can grow up to 8 cubic meters.

Note! The submersible pump of the required capacity must be free to pass through the plastic pipe. The diameter of the pump with a capacity of up to 3 cubic meters is about 75 mm, if the pump is more powerful, then this figure can be 100-105 mm.

The calculation is performed according to the following principle:

- For example, the diameter of the pump is 75 mm, the wall thickness of the product is 10 mm * 2, in addition, a few millimeters of gap should be taken into account. As a result, the diameter must be at least 75 + 4 + 20 = 99 mm.

- Since there is no product with a diameter of 99 mm, the closest larger value, which is 113 mm, should be used.

Note! When the pump is immersed, there should be a small gap between it and the walls of the casing. This will allow the pump to freely sink to the required depth.

Installation Features

Installation instructions are as follows:

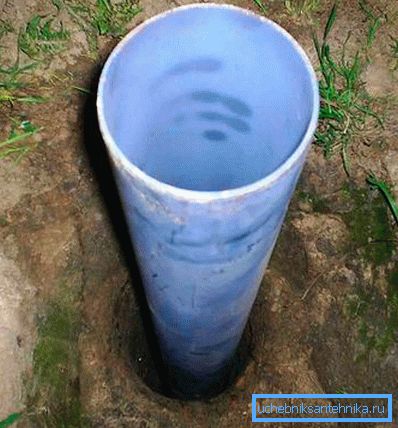

- In the first place, penetration is carried out, for example, with a 140 mm drill to a depth of 3-5 meters to the bedrock.

- Next, a 130 mm drill is drilled to the depth of the aquifer.

- After that, plastic casing is inserted for a well with a diameter of 125 millimeters.

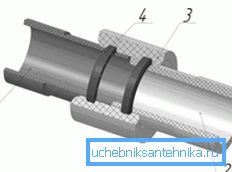

- In the process of deepening one pipe, the next part is screwed to it. Thus, the work is carried out until complete shrinkage.

Note! Threaded connection must be further sealed. This will provide reliable protection against penetration into the system.

If the well is drilled with your own hands, care must be taken to ensure that it is even, since the curvature can lead to product breakage during the installation process. Damage to the walls of the casing will also lead to a decrease in the quality of the produced water, so it is better to entrust the work on well completion to specialists who have all the necessary equipment. (See also the article How to equip a well yourself.)

Conclusion

If the well conditions do not contradict the use of plastic casing and the well itself is of high quality, then this solution is the most optimal. Otherwise, it is better to pay attention to products made from other materials, for example, steel or asbestos.

Additional information on this topic can be obtained from the video in this article.