Plastic cover for the well - the best solution

No one will argue with the fact that any well should be equipped with a quality hatch. In ancient times, instead of hatches, large stones or wooden shields were used. With the development of ferrous metallurgy, steel covers were cast from cast iron. Now metal covers have been replaced by plastic covers for wells.

Next, we will explain the advantages of plastic and reveal the simplest installation technology.

What is good plastic

In our country, hatches made of cast iron have traditionally been used, the material is excellent, but in comparison with modern polymers it loses much.

Next we will talk about the main advantages of plastic products in comparison with cast iron.

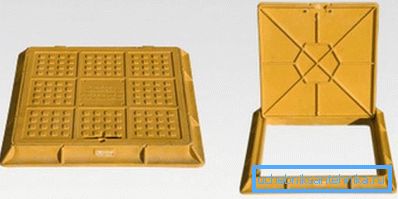

- First of all, it is lightweight plastic. If we take the total weight of the whole structure, and this is the lid itself, plus its base “shell”, then the plastic lid of the well will weigh in the region of 12 kg. While the cast-iron version will weigh at least 55 kg. For transportation, you do not need special vehicles, it can be transported in the trunk of a car or just transferred in a large package. (See also the Well or Well article — Selection Parameters.)

- Such plastic products are usually equipped with an additional locking system. This important detail allows not only to protect the mine from debris, but also to block unwanted access to underground utilities.

- Plastic covers on a well - rather durable designs. Thanks to the use of modern technologies, plus the use of chemically resistant polymers, these products are resistant to acids, alkalis and petrochemical products. The minimum warranty period of operation is 50 years, without maintenance.

- Plastic from which hatches are produced can be operated in a wide temperature range, from -80? C, to +95? C. As a result, products can be used practically throughout the entire territory of our vast country.

- Another important advantage is that the plastic from which the product is made does not collapse and does not fade under the action of sunlight. What is very important, since most products are mounted in open areas.

- Plastic covers for a well are issued in rather wide color range. This allows you to choose a product that is in harmony with the landscape design.

- Also an important factor is the safety of the structure. The fact is that in underground mines and wells there is a high probability of accumulation of explosive gases and as a result of cutting out a random spark when opening or closing a metal well, these gases can explode. Plastic products are free from such a drawback.

- It is no secret that in our country, so far, there are metal hunters and a cast-iron well cover for them is an easy prey. The plastic cover on the well, from this point of view, is of no interest.

Classification and installation technology

What designs are produced

In our country, these products are classified in accordance with the requirements of GOST 3634-99.

This regulatory document was developed on the basis of the European equivalent of EN124, according to which the structures are divided into the following classes.

- Marking A15 is assigned to products that can withstand a load of one and a half tons. They are designed for installation on pedestrian pavements or lawns.

- Marking B125 is assigned to products capable of withstanding a load already at 12.5 tons. Such hatches are installed on busy sidewalks or urban car parks intended for the parking of passenger cars.

- The C250 marking is assigned to products capable of withstanding loads of up to 25 tons. They are mounted on the carriageway of not too busy city streets.

- Marking D400 is assigned to products capable of withstanding loads up to 40 tons. They can be mounted almost everywhere, but their price is the highest for this reason, for the most part, they are installed on highways and busy city streets.

Important: for the decor of the well in the landscape design can be used plastic covers on the well, made in the form of stone boulders. For these purposes, there is a special decorative plastic cover class A15 with a box for organizing a flower bed directly on the hatch.

Principles of installation

- According to regulatory documents, the construction can rise above the ground level only in the case when the well is not located on the roadway or sidewalk, for example, a plastic cover for a summer well. In all other cases, the road surface should be flush with the hatch. (See also the cap article for a well.)

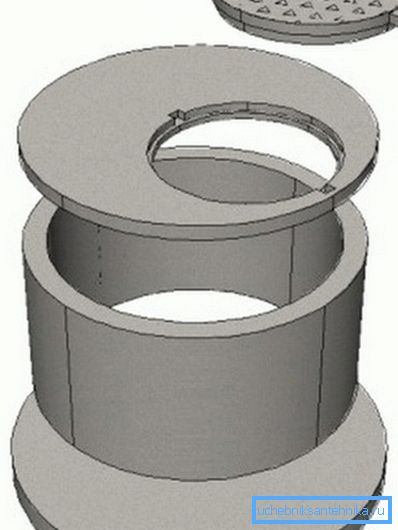

- Ideally, the installation manual is extremely simple. The basis of the design sits on the sealing ring and is attracted to the concrete neck of the well by anchor bolts.

- But, as you know, in our country it is far from always the installation of wells is carried out in strict accordance with regulatory documents and over time, the well may subside or the concrete base of the neck may twist. As a result, the correct installation of the structure becomes problematic.

- But for such cases, another, no less simple, technology for mounting the well cover has been developed, and you can do it yourself, no matter what kind of loads the plastic covers on the wells will be subjected to.

- If the pavement is already laid, and we need to replace the hatch, then retreating 30–40 cm from the edge of the well, using a jackhammer, it is necessary to hollow out the entire pavement to the concrete opening.

- In the case when the pavement is not laid yet, round formwork is mounted at a similar distance from the hatch.

- Next, a plastic well cover, or rather its base, is installed on stone or metal lighthouses. Then you should check the accuracy of the installation on the horizon with the help of the construction level.

- So that, subsequently, the solution we pour does not get into the well through the gap between the plastic base and the neck of the well, a rubber chamber is inserted into the interior of the neck from the car wheel and inflated with a compressor or a conventional pump. (See also the article Well design in the country: types)

- After that, a cement-sand mortar is made. The constitution of the solution should be liquid with high fluidity, reminiscent of sour cream. Cement for this is taken brand not lower than 500.

Important: if you are installing the structure on the roadway of a busy road, then you should use special, ready-made cement mortars designed specifically for road pavement. The price is certainly higher, but we do not recommend saving here.

- Further, the ready solution is poured around the well. The fill level should be above the base belt for anchoring, about 10 to 20 mm.

- After that, the solution should harden, the chamber will be removed and the remaining space will be filled with a road surface.

- This video in this article shows the editing process.

Conclusion

Plastic covers for wells are currently experiencing a boom. Compared with their cast-iron counterparts, they have practically no drawbacks and, moreover, they are mounted simply and quickly enough. But do not be frivolous about this process, since you are installing a structure that will stand for decades.