Plastic drainage well - the internal device and installation

Not so long ago, the builders had no choice in arranging drainage communications. A reinforced concrete product has always been used as a moisture distributor and accumulator.

However, in our time a much more advantageous solution has appeared - plastic drainage well KDN.

General information

Immediately it should be said that, contrary to popular belief about the unreliability of plastic products, the strength characteristics of such a well even exceed the similar parameters of the device of reinforced concrete. In addition, due to the construction of the design, the universality of the product is achieved.

Merits

Experts recommend using plastic wells for drainage, and there is a reasonable explanation for this:

- Saving space. Plastic structures are much smaller than concrete counterparts, which is especially important for owners of small areas.

- Savings in maintenance. The service life of such structures is up to 50 years, while reinforced concrete usually serves 5-7 years, after which it begins to collapse intensively. As a result, you have to deal with its reconstruction or the construction of new wells.

- Savings on installation work and transportation. The plastic product weighs quite a bit and is completely ready for operation; simply connecting the pipes is enough. To perform reinforced concrete structures will have to attract equipment, respectively, the price of the product will increase.

- Plastic products do not react with chemicals.

- The possibility of operation in all climatic conditions. Their working temperature ranges from -60 to +50 degrees Celsius.

- The material is not exposed to microorganisms.

- Products are not afraid of hydraulic and dynamic loads.

- If necessary, you can quickly change the height of the mine.

Thus, the choice in favor of plastic constructions is obvious.

Tip! When choosing a product, you need to pay attention to the quality, including the thickness of the walls, which should not be too thin. Otherwise, the container may deform under the pressure of the soil.

Plastic drainage device

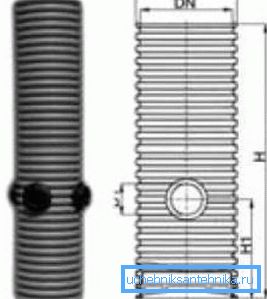

The drainage well consists of several basic elements:

- The body of the well.

- Bottom.

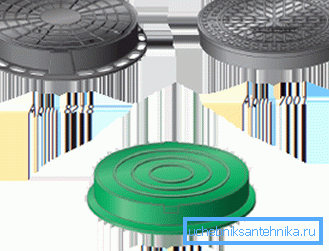

- Pig-iron or plastic manhole for the well (selected depending on the place where the drainage system is located).

Externally, the device resembles a tall glass, which is hermetically sealed with a lid on top. In its lower part, at a distance of at least 40 cm from the bottom, there are openings for drainage pipes.

Sand particles linger in the bottom space of the well. This area of the mine is called a sand trap. In addition, a drainage pumping station can be located inside the structure.

Drainage pipes are usually fixed with rubber cuffs. The height of the well and the number of conclusions depends on the depth of the pipeline.

Note! Of great importance for the well has a plastic cover, which should be tightly closed. In this case, the system will be protected from overloads caused by the ingress of rain water into it.

Materials for the drainage well

Today, manufacturers often make plastic drainage wells from the following materials:

- Polyvinyl chloride (PVC);

- Polyethylene (PE);

- Polypropylene (PP).

Note! If a person is supposed to descend into a well, then its diameter must be at least one meter.

In addition, fiberglass products have recently appeared on the market.

Types of drainage wells

All drainage wells are divided into several types:

- Inspection or inspection - they are installed at the joints of pipes. On straight sections they are set at a distance not 50 meters from each other, but on curvilinear ones - at every second turn. If this condition is not met, then soon the pipeline will have to be changed, since the turn is the most vulnerable part of it.

- The water intake well is the final element of the drainage system. In this capacity all water collected by it collects. From here it enters the general system and merges into the reservoir. Also this water can be used for irrigation.

- Absorption - this design differs from the previous two in the absence of the bottom. This well is a way out of a situation when there is no possibility of discharge of sewage. Its installation is carried out on a pillow, which consists of a layer of rubble and sand, this allows excess moisture to go to the lower soil layer.

Installation of a plastic well

All components of the product have a low weight, so the installation is not difficult to do it yourself. For example, a device with a diameter of 90 cm, height 152 cm weighs about 30 kg. Therefore, this work does not even need a lot of helpers.

Immediately it should be said that the correct installation of the drainage device should be carried out at a depth of 50-70 cm from the line of passage of the pipe. Thus, the well is the lowest-lying element of the entire system.

Installation instructions for the device are as follows:

- First of all, it is necessary to level the bottom of the pit, and then fill it with sand to a height of about 10 cm.

- Then, if necessary, the corrugated pipe should be cut to the desired height. You can do this job with a hand saw.

- Next, connect the places of transitions using a plastic sleeve with a rubber seal. Silicone sealant can be used for better sealing.

- After that, a thorough cleaning of the socket of the chute is performed, a sealant should also be applied to the joints.

- Next, set the mine in the bell bottom. This operation should be done using the indentation method.

- Then the drainage pipe is installed.

- After that, the bottom of the well must be filled with fine soil. The operation is performed in layers, with a uniform compaction over the entire area.

- At the end of the work set the hatch for the well.

At this assembly installation is completed.

Conclusion

To date, plastic drainage wells are the most popular, which is explained by all of the above advantages. Besides, their installation does not require much time and effort. But the most important thing is that such a drainage system will last for many decades.

Additional information on this topic can be obtained from the video in this article.