Plastic hatch for the well - practical, comfortable,

Any engineering communications located underground require periodic maintenance and inspection. To access them are equipped with wells, the necks of which are often located on roads, pavements, lawns, squares.

In order to prevent accidents and foreign objects from getting inside, reinforced concrete, cast-iron and plastic hatches for wells are used to isolate them.

The advantages of polymer products

A well hatch must ensure the safety of engineering systems, preventing exposure to precipitation and other external factors. On the other hand, it should exclude the injury of pedestrians and animals, ensure the safe movement of vehicles. To do this, it must be durable, withstand severe mechanical loads and environmental influences.

Therefore, until recently, hatches were made from materials such as cast iron and reinforced concrete, which fully met the specified requirements. But the emergence of modern polymeric materials made it possible to replace them with more practical and convenient plastic hatches for wells.

What are their advantages?

- In the first place - it is a much smaller weight of the product compared to cast-iron analogues. The plastic hatch of the same size and volume as the cast-iron weighs 4-6 times less. And this ensures the simplicity of not only its installation, but also transportation.

- In the production of polymer products are used components that are not susceptible to corrosion, resistant to the effects of corrosive substances - reagents, gasoline, motor oils, etc., used for treating roads.

- Long service life. Well cover will last at least half a century, without requiring repair or replacement.

- High degree of interchangeability. The new polymer hatch can be installed not only in the place of the same lost, but also in the ring designed for the cast-iron cover. (See also the cap article for a well.)

For reference. To prevent theft, deliberate damage to the hatch or unauthorized access to equipment located in the well, it is recommended to install products with a special lock.

- The ability to install and operate in any climatic conditions from the Far North to the southern regions of the country - the polymer material from which hatches are made, is intended for use in the temperature range from -50 to +70 degrees Celsius.

- Safety operation. Plastic components do not contain toxic and carcinogenic substances hazardous to human or animal health.

Note. When opening or closing a heavy metal hatch, there is a high risk of accidentally sparking a spark. This can threaten the explosion of gases, which often accumulate in deep underground wells. With plastic covers for wells it is possible not to be afraid of it.

- Plastic is not the kind of material that might interest fans to profit at the expense of others. A manhole made of it, unlike cast iron, cannot be turned in for scrap, having received money for it. Therefore, even unlocked products are usually not stolen.

- Low price is another advantage of this material. And to pay less will be required for the products themselves, and for the installation, and for their transportation. And one or two hatches can be delivered to the place by yourself, using a private car or simply putting it in a big bag.

- Wide range and high decorative characteristics. The range of colors of plastic hatches is so large that it allows you to pick them up to any surface - green lawn grass, gray asphalt, colored paving slabs or paving stones. (See also the article Decorative wooden wells: design options.)

- At the same time, colored plastic is made using heat-resistant pigments that do not fade under the action of ultraviolet rays. Therefore, products that are mostly installed in an open area do not lose their original color brightness throughout the entire life cycle.

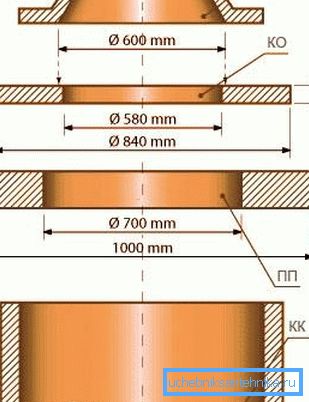

- Large selection of sizes - from inspection hatches with a diameter of 315 mm to large ones with a diameter of 1000 mm and more, which allow the well to go down into the shaft.

Note. If you want to make the hatch not just less noticeable, but also generally invisible and do not spoil the impression of the landscape design of the territory, you can install a decorative cover in the form of a stone or a special box for organizing a flower bed with fresh flowers.

Polymer Manhole Classification

The products described are classified by purpose, strength and form.

Classification by purpose

The plastic hatch on the well is marked depending on the purpose with certain letters:

- B - to the water well;

- K - to the wells of household or industrial sewage;

- D - to the rain sewer;

- G - on the fire hydrant;

- GTS - to the telephone network;

- TS - to the heating network.

Strength classification

Sewage manholes, depending on the installation site, should be designed for a certain load, and therefore they are divided into several classes:

- Class A15 - the hatch can withstand a load of one and a half tons and is installed on pedestrian and bicycle paths and in green areas;

- Class B125 - maximum load up to 12.5 tons. Mounted in areas of active pedestrian traffic, in car parks for cars;

- Class С250 - a hatch capable of withstanding a load of 25 tons, is installed on wells located near curbs and on city roads;

- Class D400 - this hatch is able to withstand up to 40 tons of weight and is installed in parking lots for all types of vehicles, on the carriageway main roads and fortified roadsides;

- Class E600 - maximum load of 60 tons. Such hatches are used in industrial zones, areas of unloading and loading of goods and in other areas with a high load on the surface;

- Class F900 - the most durable hatch capable of withstanding up to 90 tons. It is installed on runways, in ports, in container zones, etc.

For reference. Depending on the required strength, the requirements for the component composition of products change. They can be made only from polymers or from polymer-sand mixture.

Classification by form

The shape of the hatch can be any, including rectangular or square. But the maximum distribution has received all the same round shape. This is due primarily to the fact that such a cover is guaranteed not to fall into the well when careless movement or as a result of someone's intent. While the diagonal of a square or rectangle is always larger than any of its sides, therefore, the fall of such covers downwards is not uncommon.

Installation of plastic hatches

Install a plastic hatch is quite possible with their own hands. At the same time you need to know that it must be flush with the surface so as not to interfere with traffic or pedestrians. Exceptions are allowed only in cases where the well is located on the lawn or in other places without heavy traffic.

The design of the hatch is such that the installation work is carried out only relative to the support ring, in which there are technological holes for attaching to the concrete base with anchors or its reliable concreting. The lid itself, which has guides, simply fits into the ring to align with the corresponding grooves.

But often there are situations when the bottom of the well was skewed or turned out to be below the surface, for example, as a result of repairing the road surface.

In such cases, the following instruction will help you install the door:

- A formwork is installed around the manhole into the well at a distance of 30-40 cm from it. Or, if the edge of the hole is located below the surface level, a coating is hollowed around it until the concrete neck is completely exposed.

- The support ring is installed in place, leveled and fixed on metal or stone "beacons".

- If there is a gap between the support ring and the concrete cap, it must be closed so that the solution does not flow into the well during pouring. To do this, the easiest way is to insert a rubber car chamber into the neck and inflate it so that it stays in it without additional support.

- After completion of the preparatory work, concrete mortar is poured into the formwork or space hollowed around the ring, the grade of which must correspond to the appearance of the surrounding coating.

- The solution is allowed to harden well, after which the chamber is removed from the neck and the signal fences are removed, which are necessarily put up around the well for the period of repair work.

Difficult situations with reinstalling the hatch can be avoided if you immediately mount a well with a telescopic adapter on the neck. It will allow without any extra effort to change the position of the hatch in height or to install it with the necessary slope.

Conclusion

Compared with heavy and massive cast-iron hatches, plastic is more practical, durable and safe. They are easier to install or replace if necessary. We have already described how this is done, but you can additionally watch the video in this article on this topic.

Due to their high characteristics, these products are particularly popular today, leaving their cast-iron and reinforced concrete counterparts in hopeless outsiders. What is not surprising - few people will refuse the convenience and practicality of modern products, especially if they have to pay less for them.