Plastic plumbing: what pipes and equipment for it is best to

A couple of decades ago, metal pipes were almost the only material for the construction of water supply networks. However, now an increasing number of owners of apartments and private houses are trying to install plastic plumbing with their own hands. This option is more preferable due to the best characteristics of polymer products.

Types of polymer pipes

At the moment, the most common pipes, the material of which relates to thermoplastics:

- PE - polyethylene products;

- PVC - polyvinyl chloride analogues;

- PP - polypropylene products;

- PE-C / Al / PE-C - products made of cross-linked polyethylene, reinforced with aluminum.

Plastic products, most often used for plumbing

Now a little more about these types of pipes.

- Polyethylene analogues are used for external and internal water supply networks, sewage and drainage. They are able to withstand a working pressure of 6/10 atm. They can be operated at the lowest operating temperature (-20 degrees).

For the installation of such pipes used plastic fittings for plumbing (fittings) or electrofusion couplings. There are products from two types of material - high pressure polyethylene (LDPE) and low pressure (HDPE).

- Cross-linked polypropylene has high strength and temperature properties. For the installation of pipes from it, plastic plumbing taps and other crimp-type fittings are used. The main sphere of their use - the system of "warm floors".

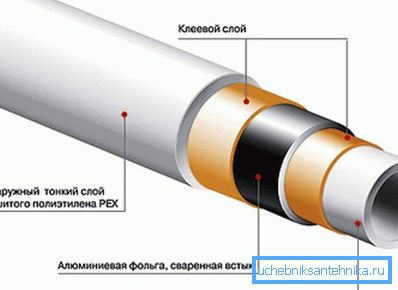

- Metal-plastic production consists of two layers of cross-linked polyethylene and an interlayer of aluminum foil located between them.

Note! The material has easy installation and very high performance. This gave him the opportunity to become the most popular for arranging hot water supply and heating.

If you are constructing a water supply system with your own hands from metal-plastic, please note that it can withstand the temperature of the working medium up to +95 degrees, and the pressure - up to 10 bar.

- PVC pipes appeared one of the first. For their conjugation, the method of “cold welding” (glue) or a socket with a rubber cuff is used. They have good performance and low price.

Product Benefits

- Long service life - about 50 years.

- Resistance to air, electrolytic and chemical corrosion.

- Low thermal conductivity makes it possible to use plastic products for hot water supply and heating.

- The relative speed and ease of installation of the pipeline.

- You can use your own hands for open and hidden networks.

System installation

- Installation of plastic plumbing with your own hands is quite convenient, since minimum connections are applied. This reduces the risk of leaks.

- The network sections are 4 m long and are interconnected by heated fittings. This makes it possible to quickly assemble the system.

- If we strictly adhere to the soldering technology, then the welded joints will not reduce the reliability and tightness of the pipeline.

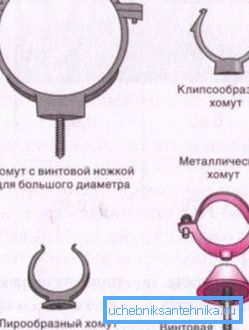

- Thermal expansion of a plastic system is higher than that of metal counterparts. It can be reduced by properly selecting the overall network configuration, including the location of the supports and fixtures.

Note! When installing a plastic pipe, it is important to observe one rule. The network must be as flexible as possible. It is desirable that she had a minimum of short sections with a high degree of rigidity.

Consider the following points.

- It is recommended to fix the pipes themselves to the ceiling and walls with the help of sliding (movable) supports, in 1 meter increments Fixed analogs fix valves and related equipment: counters, filters, valves, gate valves, etc.

- Chemical resistance and good durability allow the use of plastic pipes for underground external networks. A good choice would be plating the plumbing riser plastic.

- If the products will be used for laying in the ground, they should be protected from mechanical influences.

- To interface polymer pipes with metal elements (valves, filters, meters, mixers, etc.), you should use a combination of detachable fittings with metal inserts.

- Do not wrap a thick layer of sealant on the threaded connections (fum-tape, tow, etc.).

- Do not apply excessive force when tightening the connections. Otherwise, you can squeeze the metal insert out of the fitting.

- For the bending of polymer pipes can be used building dryer. At the same time, the heating temperature should not be higher than + 1400 °.

- On straight sections of the water supply, with a length of more than 3 m, it is necessary to install factory ring compensators or welded counterparts.

A little about the external part of the network

When installing the outer part of the network, plastic wells are often used for plumbing. These structures are used to accommodate the valves that regulate water flows.

They are produced using extrusion welding. The material is a spiral-twisted two-layer pipes made of polyethylene, having a reinforced ring stiffness.

Characteristics of a plastics water well are shown in the table.

| Diameter internal (D), in mm | 900, 1000, 1200, 1400, 1600, 2000 |

| Depth of construction (N) | up to 6 meters |

| The diameter of the pipes (dp), in mm | 110, 160, 200, 250, 315, 400 |

| Wall thickness, in mm | 25, 44, 62, 75 |

| The diameter of the internal neck (d), in mm | 700 |

| Neck height (h), in mm | 250 |

Drip irrigation with plastic tag

Each summer resident - the owner of a garden, vegetable garden, flower garden, knows that the main condition for the normal growth and development of plants is their timely watering.

When the territory is large enough, you don’t really run around with a bucket and a watering can. It is expensive and difficult to build plastics plumbing wells and pull hoses away. The best way out is to equip a drip irrigation system.

This method of irrigation is advisable if you come to the site periodically. Country craftsmen for this purpose make plumbing from plastic bottles with their own hands.

Such container provides uniform watering of plantings within 2/4 days. Of course, it is advisable to apply the drip method on not too large areas. Basal irrigation is more preferable to many vegetables, since water, falling on the leaves, can cause illness.

For example, root irrigation of tomatoes, cucumbers, eggplant, etc., can be done using 1.5 / 2-liter bagclazh.

- The bottom of the bottle is cut off, the lid is tightly screwed onto the neck, several holes make holes on either side of the bottle.

- Should take into account the composition of the earth. When it is sandy, two holes will suffice, if the soil is clay, dense, you need four.

- Next, the bottle digs in between two bushes of plants. This should be done at a depth of 10/15 cm, head up.

- Now you can pour water. It will gradually trickle through the holes, and feed the root system of plantings.

You can boil the water and hang (on a wire) over each of the bushes. Holes in this case are made in the bottom or bottle cap.

Conclusion

Plastic plumbing has a number of indisputable advantages over metal counterparts. It is modern and reliable. You can mount it yourself.

Watch the video in this article. It contains a lot of complementary information.