Plastic sewer wells: design and installation features

Concrete and plastic wells for sewage are used to provide access to the pipelines for the purpose of checking, preventing and repairing them. The choice of one or another option when designing a sewer system is determined by the peculiarities of operation, financial possibilities and a number of other factors.

Below we consider in detail exactly the plastic products, and also pay attention to the features of their installation.

Purpose of wells

As we noted above, the main function of any sewer well is to provide access to the pipeline without excavation.

At the same time, depending on the location of this part, the following groups are distinguished:

- Inspections, they are the same revision. They are installed on flat sections of the pipeline at a certain interval. The main function of the manholes is to enable the state of the pipe to be monitored and, if necessary, determine the location of the blockage. The step of mounting the inspection points for highways with a diameter of up to 110 mm is 20 meters, and up to 150 mm - 35-40 meters.

- Swivel. As the name implies, are mounted in areas where the sewer pipe turns. It is impossible to do without them, since it is on the bends that the flow speed decreases, and the risk of a traffic jam increases.

- Nodal. Provide the intersection of several highways. Most often used in industry, since in private construction such situations are rare.

- Delta. Used to design the connection of two pipes, which are placed at different heights.

Note! In order to save, you need to equip multifunctional systems, combining, for example, a turning point with a place of revision. In this case, the total cost of the system will be somewhat lower.

According to regulatory documents, such structures must be installed:

- On the sections of the turn.

- At connection of several pipes or in the place of joining the pipe with the main.

- In the place of changing the diameter or slope of the pipe.

As you can see, the range of application of these parts is quite extensive. Below we will try to understand all the nuances of their design.

Plastic products

Materials

As we noted above, wells for sewer networks can be made from both reinforced concrete and plastic. At the same time, polymer products have recently been the most popular.

Such constructions entered the modern market about 20 years ago. To date, they have replaced concrete in approximately 40% of European sewer networks. We have this figure significantly lower (hopefully for now), but gradually the share of plastic inspection shafts is rising.

The following synthetic materials can be used to manufacture these parts:

- Polyvinyl chloride. Differs in high durability, however at strong decrease in temperature becomes brittle.

- Polyethylene. It is elastic, but badly transfers long static loadings, losing durability on bends.

- Polypropylene. Possesses high operational structures, however the high price acts as the limiting factor at distribution of these products.

Also, relatively recently, systems based on combined materials and devices, in which large diameter pipes act as supporting elements, have gained popularity. An example is the sewer plastic wells from KORSIS pipes, whose corrugated shells provide excellent load bearing capacity.

Design features

A typical well consists of only a few parts:

- The neck, which is mounted flush with the surface of the earth. Usually the neck is supplied with fasteners for mounting the hatch. (See also the article Features plastic manhole for the well.)

- Mine, connecting the neck with the bottom, the working part.

- Tray in which the connection is carried out pipes.

As for the design schemes, there are also a few of them.

The most frequently encountered structural elements include the following:

- Telescopic tube, moving freely relative to the shaft. Using a telescope with a saddle to mount the hatch allows you to mount the well to the desired depth, facilitating the positioning of parts.

- The conical part connects the tray with the shaft or the neck. The use of conical adapters allows you to mount large trays under standard-sized hatches.

- The body of the well can be either solid (then a pipe is used for its manufacture) or assembled. Prefabricated structures are made up of rings, which are hermetically connected to each other during the installation phase.

- The bottom of the tray is often combined with a kinet - a special splitter for several pipes. Kinetta must be selected depending on the configuration of the sewer network, so that we do not have free connections.

Product Benefits

The designs described above have a number of advantages that allow them to gradually oust concrete products of a similar purpose from the market.

- The case has a high mechanical strength.

- The walls of pipes and trays are resistant to chemically active substances.

- The design of the neck, shafts and kineta makes it possible to realize almost tight connections with minimal labor costs.

- The use of plastic as the main material, as well as the use of corrugated tubes for the manufacture of bearing elements, allows the construction of structures of various shapes and sizes.

- A relatively small mass of products greatly facilitates installation.

Installation technology

If you made a choice in favor of plastic and purchased a well, the dimensions of which correspond to your tasks, you can install it yourself.

The algorithm of actions in this case is as follows:

- To begin with, we dig a pit, the depth of which is 30 cm higher than the height of the well.

Tip! It is necessary to choose the depth so that the laid pipelines enter the kinet without a height difference. It is better to do this at the design stage of the entire system.

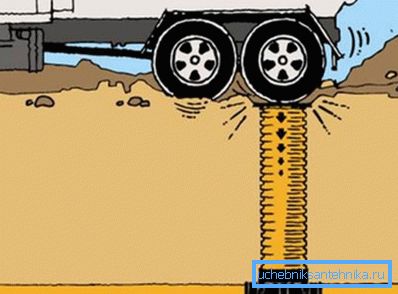

- The bottom of the pit is carefully aligned. Pour a layer of sand mixed with gravel on the leveled surface. Layer thickness after tamping should be up to 20 cm.

- Pour a concrete screed over the sand pillow. The thickness of the screed is from 50 to 100 mm.

- After the concrete has dried, we install the bottom of the well or a tray with a kinet. We attach pipes to the thrust, ensuring tightness of all joints using rubber couplings.

- If necessary, perform a trimming of the neck to the desired level. As a rule, the material is well cut with a conventional saw.

Tip! Cutting should be carried out in the midline of the protruding rib of corrugated tube.

- We connect the bottom with the vertical part (telescopic tube or corrugated neck), sealing the joint with silicone. From above we establish a rim and a cover of the hatch. (See also the article Plastic well cover: how to install.)

Next we need to fill the gap between the walls of the pit and the well itself. The instruction recommends to carry out the filling layer by layer, sand and gravel with the addition of clay.

Conclusion

Sewer wells made of plastic are a complete replacement for traditional concrete structures. Moreover, in a number of parameters (durability, ease of installation, etc.), they seriously surpass systems made of reinforced concrete rings. You can study these products in detail by viewing the video in this article.