Plastic well pipe - all you need to know

As you know, a well can be arranged in several ways and with the use of various technologies. This is easy to see if you call several manufacturers of this kind of work. Each of them will offer their version as the most optimal and reliable.

In fact, these statements have little to do with the actual data. Each organization simply works with certain materials, has a range of equipment and specialists who are competent in a particular field. Therefore, it offers an option that can do the best possible and, you see, this is also good.

Therefore, you just need to study the proposals and find the appropriate option. Someone uses plastic pipes for wells, someone - steel or asbestos-cement. What material will be optimal in your case depends on the type of soil.

The main types of pipes for wells

Consider the main types on the market:

- Steel pipes - the classic version, used for a long time. Proved very well - the service life of the material is about 50 years. This group includes galvanized and enameled options. And one more version - stainless steel, reliable and durable material with a huge resource.

Important note! Do not listen to those who claim that using steel, your water will always be rusty. Rust can be eliminated with the help of the simplest filters for a well. But zinc compounds from the galvanized layer can not be removed from the water, and they are very harmful to human health.

- Asbestos-cement variants - a classic method used for more than a century.. Contrary to popular belief, the material is harmless to health. But the weight of asbestos-cement products is significant, and the walls are thick to ensure reliability, under them you need to beat a larger well, which is associated with unnecessary costs.

- Plastic pipes for the well have appeared quite recently, but have already gained wide popularity due to a number of positive properties of the material and low weight, which greatly simplifies the transportation and carrying with your own hands. Below we take a closer look at the features of this species.

Selection of a specific option

In fact, the choice of the type of material depends not only on your preferences, the decision must be applied on the basis of several factors:

- The presence of saturated aquifers in the upper part of the soil.

- The presence of moving layers of soil, this factor is very important for the well, since these layers (the so-called “quaffs”), have a very large deformation effect on the aquifer.

- The depth of water intake, many materials are not suitable when the aquifer is located very far.

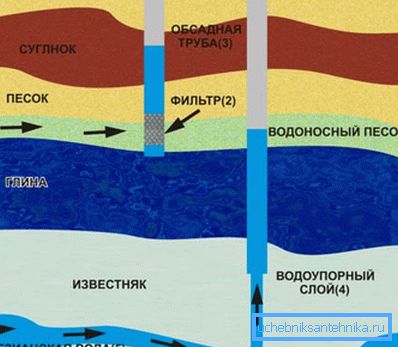

- Scope of application - the casing pipe is put as a skeleton of a well, with shallow depths it is also used as an operational one. In other cases, the production pipeline is inserted inside the casing, this is called a well in two pipes.

The main features of plastic pipes

Immediately, we note that plastic can also be different, there are several types that differ in the characteristics of the production process.

Types of plastic pipes

- PVC pipes for wells are made from unplasticized polyvinyl chloride, which gives it many positive properties. Most experts believe this is the best option: at a very reasonable price, the quality of the material at the highest level.

- HDPE - these products are made of low pressure polyethylene. This option is also quite common, but the masters believe pipes made from this material are not very reliable.

- PP - if the products have such a label, then they are made of polypropylene. It is a fairly reliable material, widely used for the manufacture of various products. Such pipes are durable and are not afraid of various chemical influences.

As noted above, most experts are inclined to believe that PVC pipes for wells is the best option for setting wells. It possesses the highest operational properties.

The main advantages of this material

- With a qualified installation and no damage, such wells will serve more than half a century.

- Plastic is absolutely immune to corrosion, it does not emit any mechanical impurities and harmful substances into the water. Moisture does not affect the strength of the material.

- This group of materials is not subject to almost any chemical attack. It distinguishes it from metal and asbestos.

- It is several times lighter than analogs of metal and especially asbestos-cement.

- Water intake made of plastic can be disinfected using special tools. The material is also perfectly tolerate the effects of the compositions used for the regeneration of water intake. These products are dangerous for asbestos and metal.

- Threaded connections on plastic products provide the highest reliability and tightness.

- The price is democratic, it is much lower than that of its counterparts in metal, but slightly higher than that of asbestos-cement options, but they are much more difficult to install and transport.

- Convenience of installation: connection with the help of a thread is made simply and easily, special instructions are not needed here, the main thing is accuracy.

Note! When choosing a particular option, pay attention to the pipe was pressure, it ensures its high resistance to external and internal pressure.

Features of the use of plastic

It should be noted that plastic pipes can be used as casing at a depth of up to 50-60 meters. The material can not be used on complex soils, as it is less resistant to deformation than steel.

Argued that the Abyssinian well of plastic pipes - an option from the realm of fantasy. Meanwhile, if it is done not by blocking, but by drilling, plastic is quite suitable, since the depth in such wells is small.

Conclusion

Plastic is great for shallow wells on normal soil types. If the device is used in two pipes, then this is an ideal option for the operational pole. The video in this article will clarify some issues in more detail.