Plastic wells as an alternative to concrete counterparts

In place of the traditional designs come modern systems - plastic wells for water that can simplify the process of construction. The base is a corrugated PVC pipe with a diameter of 31.5 to 60 centimeters. Special stiffeners increase the reliability of products when the soil is exposed to depth.

General Product Information

Modern plastic wells are not in vain equipped with special corrugations, because such a device makes it possible to transfer all kinds of loads from the ground cover without damage. Such a design for water intake can be prefabricated or seamless. For filtering, a geotextile cloth is usually used, which is wrapped in two layers (see also the article Cleaning of wells - a necessary procedure).

Product Benefits

The most important advantage of such products is tightness, especially if a seamless plastic well is used. However, with the help of a unique technology of joining individual elements, it is possible to achieve good results for prefabricated structures.

All fragments are connected with the use of rubber seals, designed for long service life.

- The ability to do their own hands saves on installation.

- Resistance to ascent is achieved thanks to the corrugated structure, so there is no need for additional fastening.

- The low weight of the product provides an opportunity to do without the use of heavy machinery and special transport.

- Good strength characteristics are provided due to the excellent resistance of the base material to environmental influences.

- Application in a wide temperature range (from -70 to +50 degrees) allows operation in almost all climatic zones.

- The low price makes products as affordable as possible.

Addition! The lack of moisture absorption by the material guarantees a long product life, which cannot be said about reinforced concrete analogues, which are prone to destruction during freezing and thawing cycles.

Terms of use

A plastic well is installed for drinking water only in areas with suitable climatic and natural data. At the same time, the maximum depth of the lower part is recommended to be up to six meters.

Backfilling is done with fine gravel or sand.

- Seismic activity in the region should not exceed 7 on the Richter scale.

- It is not allowed to use at temperatures of air in the winter period below -50 degrees.

- Installation on dry and wet soils is possible, but they must comply with standard specifications.

Note! The composition of the soil and many other circumstances do not adversely affect the product, so it successfully operates with excessive flowability, high moisture content and the presence of a large number of stones in the ground.

Self install

If desired, you can build yourself a well from plastic rings or a seamless pipe. In the first case, the design is assembled from individual fragments that have a sealing gasket made from high-quality rubber. Another option is to use a solid pipe.

Applied tools and materials

- To prepare the pit, you will need an ordinary shovel.

- With the help of a drill, holes will be made for water penetration.

- Geotextiles are used as a filter element.

- Plastic pipe is the basis of the well.

- The wire in the shell is needed for fastening the canvas.

Carrying out the main work

This instruction considers the installation of a solid pipe, but the plastic collection well is installed on the same principle, with the only difference that during the work the individual components are connected into a single complex. The combination of components is made through convenient locks.

As for tightness, it is achieved through a rubber seal.

- At the initial stage, a two-layer pipe made of polymer with a diameter of 40 to 60 centimeters is prepared. This product must be intended for use in soils.

- Next one of the many ways is the aquifer. To do this, you can use the method of biolocation, folk omens, or make exploratory drilling.

- After determining the location of the water, a foundation pit is digging beyond the diameter of the pipe to avoid problems during installation. It is desirable to dig a hole continuously, then it will be possible to prevent sticking of the column.

- When sand appears, it is necessary to make a rounded hole in which a similar base will fit. The digging continues until in depth it does not hammer the key.

- Now the plastic insert is being prepared in the well properly. From the bottom about 50 cm in height there is a perforation between the ribs. To do this, use a drill with a thickness of 7 mm.

- The hole of the pipe and the perforated part are covered with geotextile in two layers. Fastening of a cloth is carried out by a special wire which has a protective cover.

- The base is transferred to the place of installation, and then gently goes down. After installation, the pit is filled with sand around the pipe. The upper part is additionally insulated.

- Inside the submersible pump is lowered, with which water is pumped. This action is carried out before entering the clear water. A layer of quartz sand is placed in the lumen of the structure for better cleaning.

Attention! If repair of a reinforced concrete shaft is required, you can simply insert a plastic liner into the well to avoid time-consuming operations to repair the water intake structure.

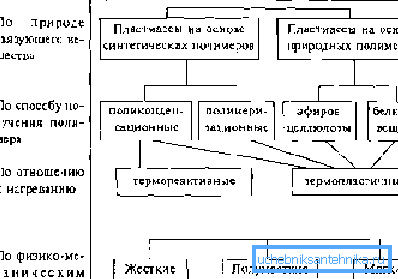

Used types of plastic

Plastics are organic materials that are based on natural or synthetic high molecular weight compounds. All of them can be brought to a liquid state by heating and pressure, and after cooling, they can retain a certain shape.

Highlight should be the main varieties.

- Polyvinyl chloride (PVC) It is a thermoplastic polymer of vinyl chloride, therefore it is distinguished by high chemical resistance to many substances. It is difficult to ignite in the open air. However, plastic water-measuring wells, which require reliable protection from the environment, are most often made of PVC.

- Polyethylene is a thermoplastic polymer of ethylene, which has received the widest distribution in the world. High-density products have a reduction in HDPE, and low - LDPE. The material is resistant to aggressive media, as it does not react with alkalis of various concentrations, as well as with salt solutions.

- Polypropylene formed due to polymerization of propylene with the participation of metal complex catalysts. It has a higher melting temperature index than the previous equivalent. All products made from this material are able to withstand boiling, which means that they can even be subjected to steam sterilization, while the mechanical properties will not change.

As a conclusion

The above information is designed to familiarize individual developers with modern products for collecting water, used as an alternative to reinforced concrete rings. Having examined in detail the plastic wells and the process of their installation, you can get a complete picture of the products (find out here when it is better to clean the well).

And additional information can be obtained by looking carefully at the video in this article.