Polycarbonate shower - a simple and practical option to give

The appearance of such a material as polycarbonate did not go unnoticed, people appreciated its strength, durability, low weight and ease of processing. Particularly he liked the owners of suburban areas, not only a cozy greenhouse can be made from it, but also a fence, and a visor over the porch, and even a polycarbonate shower with his own hands is quite real.

What can you do in the country

When building a shower stall at the dacha, as a rule, the main criterion is the low cost. Of course, the appearance also plays an important role.

Depending on the degree of capital construction can be identified such options for the device shower:

- shower toptun with curtains. In this case, you will need to purchase only the water supply device itself. The frame can be made independently, and the usual walls can be replaced by regular hard curtains. The price of this design is minimal compared to the others;

- sometimes sheeting corrugated sheeting and even slate are used for sheathing the frame, but this design looks, to put it mildly, unsightly;

- a wooden shower can already be attributed to more serious constructions, however, the tree, despite all the tricks, will still rot over time, and the insects will do their bit;

- brick option can be considered the best option in terms of durability and reliability. But the time spent (and financial) do not allow to call it especially popular;

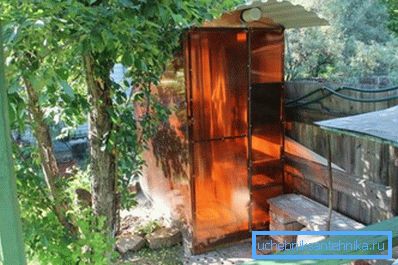

- polycarbonate garden shower can be considered a solution that combines the advantages of all the options described and has almost no drawbacks.

When using polycarbonate for the construction of the shower is achieved:

- high speed of performance of work. This material is supplied in sheets that are cut out already in place;

Note! In order to cut the sheet, you need only the usual office knife.

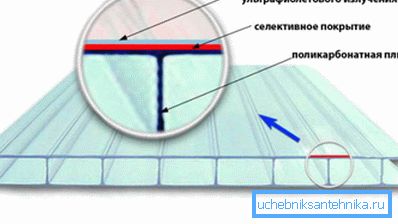

- high thermal insulation - this is important if the shower is planned to be used not only in the hot summer, but also in the autumn-spring period. Polycarbonate has a low thermal conductivity due to its cellular structure;

- polycarbonate showers can withstand both the summer heat and winter frosts, the operating temperature range for this plastic is from -40? С to +120? С;

- saving. The low cost can also be added to the asset of such shower cubicles, you can buy a sheet of colored plastic with dimensions of 2.1х6.0 m and a thickness of 10 mm for only 4,600 rubles, with 1 m2 will weigh about 1.5 kg;

- durability. Simple polycarbonate degrades under the influence of UV rays, but manufacturers have learned to eliminate this drawback - they simply add a film that reflects UV radiation, while the sheets themselves remain translucent, so that day will always be light in the shower.

The issue of protection from unwanted observers is also solved quite simply. All you need to do is get an opaque polycarbonate for the shower. Light sheets of such pass, but something to see through them is almost impossible.

Planning and building a shower

There are several construction options, ranging from the simplest (the foundation is not provided at all) and ending with the construction of strip foundations and the installation of a drain hole. We will focus on the intermediate version - the foundation will be columnar, and the pit will be located directly under the shower.

Little about planning

It is better to spend a little time and at least by hand to draw a plan of the site and the approximate location of the shower stall on it.

Summer shower with polycarbonate hands should be placed on the site with the following requirements:

- it is undesirable to place a cabin in the center of the site in a well-viewed place. It is better on the contrary, to hide it in a secluded corner, it will just be psychologically more comfortable;

- it is better to remove the drain hole as far as possible from the well or well, and in case of high groundwater levels, it will be necessary to completely abandon its structure;

- Most likely, the sun will be used to heat the water, so the shower should be well lit at noon.

Note! It is necessary to take into account the terrain. If you place the shower in the lowland, then during the rain the water can fill the drain hole and it will be impossible to use the shower for a while.

If there is a sufficiently large greenhouse on the plot, then you can consider the option of a polycarbonate greenhouse shower. In this case, we get a year-round functioning shower stall, and if we limit ourselves to the use of household chemicals, the flow can be directed to watering the plants.

A few tips on building

If the proposed procedure is followed, a polycarbonate shower room will last a long time with its own hands, and a shower can be taken not only in summer, but also on a cool autumn day.

When building it is recommended to adhere to the following procedure:

- although the load from the frame and plastic lining will be small, it is still best to arrange the foundation. To do this, it is enough to dig holes in the corners of the future booth under the posts (you can use a hand drill), plastic or asbestos cement pipes can be used as fixed formwork, concrete is poured inside the pipe, it can also be concreted outside;

Note! The instruction requires mandatory sand-crushed stone pillows at the bottom of the pit.

- when concreting the pillars around them, a small blind area is made;

- a drain hole rummages under the future cabin and is filled up with large rubble; it is not a bad thing to arrange a layer of rubble in the whole area under the cabin;

- after the concrete hardens, you can proceed to the construction of the frame. It is allowed to use both a metal profile, and a tree (wood before it is impregnated with an antiseptic). Work begins with the installation of the bottom trim and its attachment to the concrete foundation with metal pins;

Note! In the case of a metal frame, both welding and bolting can be used to join elements (in this case pipe couplings are used).

- then you just need to install the vertical uprights and to ensure rigidity fix them with braces. It is possible to build a shower with a dressing room, that is, to divide the space into 2 zones, this will not greatly complicate the work;

- after installing the top trim on the roof, a water tank is installed and the roof is mounted. In order to maximize the use of sunlight, the roof can be made transparent;

- it is necessary to dwell separately on the door device - the principle is used the same, first the frame of the door for polycarbonate is created for the shower, and then it is sheathed with plastic sheets;

Note! It is necessary to carefully adjust the dimensions of the door to the dimensions of the opening, otherwise drafts are guaranteed.

- the final stage of construction can be considered as plating frame polycarbonate.

This question, how to make a summer shower, can be considered closed. Of course, it is possible to somewhat simplify the proposed instruction, but it is better to make the structure more or less capital.

Summarizing

Polycarbonate outdoor shower is a very convenient thing, practical and, most importantly, inexpensive. It can be built in just a few days, and such a construction will last for more than one decade. In this case, all the work can be done on their own, so that you have to spend money only on building materials.

The video in this article shows the construction of a simple soul made of polycarbonate sheets.