Polymerplate well rings overview

Taking up the construction of the well, each person wants to make it high-quality and most resistant to all natural conditions.

The tightness and reliability of such products can affect:

- ground water

- constant dampness

- chemical substances,

- temperature drops.

And knowing that repairing a well is a rather complicated, time-consuming and expensive procedure, one should choose a material that is more durable during the construction phase.

An excellent alternative for already become familiar reinforced concrete products can be polymer sand rings for wells, the cost of installation of which will be much less, and characteristics such as strength, tightness and durability of the finished product are much higher.

Production of polymer-sand rings

A composite material with the addition of a sandy filler is used as a raw material for the manufacture of such products. Composite is a kind of plastic that is endowed with various properties with the help of various additives (see also the article Centrifugal Pump for a Well: help in choosing and features of use).

The instruction, in accordance with which well rings are made of this raw material, provides for their creation by pressing in high temperature conditions.

In the process of manufacturing under high pressure all the powder components are mixed. The resulting solution is baked, transforming into a low-porous and high-strength sand-polymer rings for wells.

Polymer sand or reinforced concrete: which is better

For a long period of time, reinforced concrete was considered the only material suitable for the construction of wells. But its properties are not ideal for this kind of structures.

Comparative characteristics

In order to understand and appreciate all the advantages of polymer-sand structures over concrete structures, one should be familiar with the comparative characteristics of their properties:

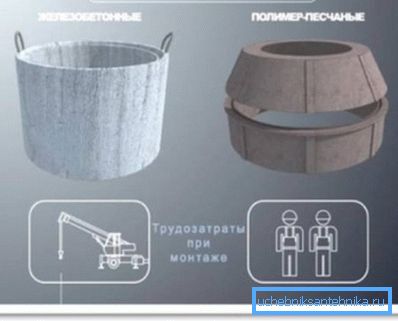

- Mass and convenience of transportation. Products from concrete and reinforcement have significant weight. Only one ring of reinforced concrete with a width of 1 meter weighs approximately 0.5 tons.

In order to deliver such a product to the construction site, you will need a crane for loading and unloading and a truck for moving. In addition, such dimensional equipment can not always drive up to the construction site.

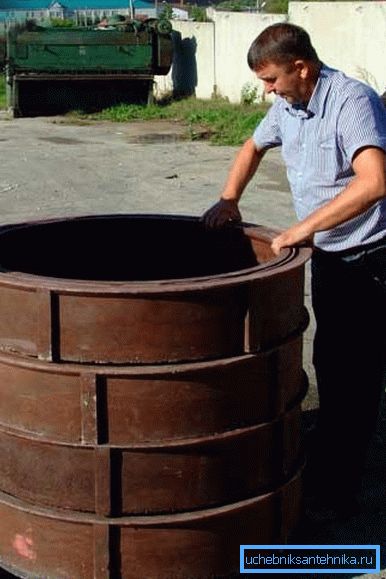

Polymer-sand well rings have a low weight. The mass of one fragment of such a structure is not more than 60 kg. Two people can quite lift and move this product. It is possible to bring products from polimepeska to the construction site by means of the car with the trailer.

In addition, these components are easily mounted in hard to reach places, because to roll such a wheel, for example, in the basement and place the owner in the mine without any help, will be able to build a well with his own hands.

- Installation process and tight joints. Reinforced concrete products do not have perfectly smooth edges, which is why builders have to pay much attention to joints during installation. But over time, the water still blurs the surface of the rings themselves, and the joints.

And if the well was built in rolling ground, then during the movement of the rings under the influence of natural conditions, the tightness of the seams will certainly be broken.

Sand-polymer rings for the well during installation are joined according to the groove-ridge technology, which excludes the possibility of movement of the structural components as a result of soil movements. This type of connection eliminates the penetration of water, and for the insurance it is only necessary to lubricate the joints with sealant or mastic.

- Moisture effects. The main enemy of any structures made of reinforced concrete is moisture. Sufficiently wide pores are present in the concrete structure, and in winter the low temperature contributes to their increase, the occurrence of microcracks, which will become wider each year.

Polymer sandstone ring for a well, thanks to high-temperature manufacturing technology, has a minimum level of moisture consumption. Such a design can withstand more than five hundred cycles of thawing and freezing, without any negative consequences.

- Chemical exposure. Groundwater coming into contact with external surfaces may contain fairly aggressive chemicals that can destroy concrete. In order to protect concrete surfaces from similar processes, they are treated with specialized antiseptics and mastics.

Polymer-sand rings for wells are not at all afraid of such aggressive media. The composite material from which they are made does not react with either acids, salts, or alkali, so additional processing is not required.

Note! Manufacturers of reinforced concrete rings provide a guarantee of 50 years for their products and no guarantees on the tightness of the joints. A polymer-sand construction is guaranteed for 100 years.

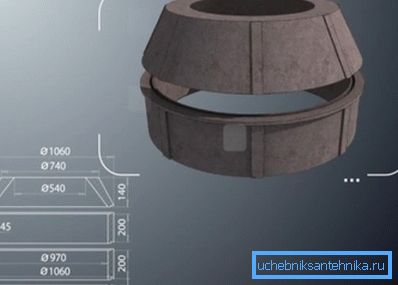

Polymer Sand Well Device

Like a reinforced concrete well, its polymer-sandy fellow is a construction of separate rings. The height that is given to the polymer sandwich ring for the well is 30 cm (find out here how to cover the seams in the well).

The deeper the shaft is needed, the more rings are required during installation.

The standard kit consists of:

- 8 rings;

- 1 adapter;

- Luke;

- Covers;

- Bottom.

The total weight of the standard height is about 600 kg.

Note! Polymer-sand manhole cover is not of interest to thieves who are engaged in the delivery of scrap metal, because there is no metal in it.

A well made of polymer-sand materials is a higher-quality, sturdy and durable construction. For this reason, every far-sighted owner must certainly understand that the higher price of polymer-sand products guarantees the minimum repair and restoration costs required for products made from other materials.

And in this article, the video in this article will help you to get acquainted with the structures from polymer sands.