Polypropylene ball valve - purpose and features

Now pipes from polypropylene gained wide circulation, thanks to a number of positive qualities. However, they require special fittings - ball valves. Actually, this device is dedicated to this article.

Special features

Ball valve for polypropylene pipes is designed to completely shut off the water supply. As a rule, the device is used in water supply systems (hot and cold) and heating.

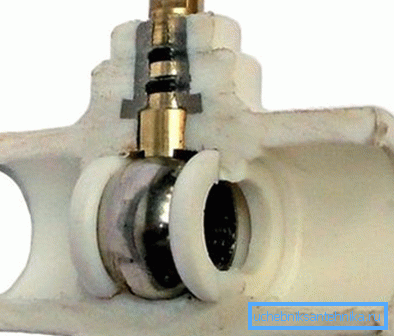

This device is called a ball because its locking mechanism is made in the form of a ball with a through hole. The ball itself, as a rule, is made of stainless steel, respectively, it is not afraid of corrosion.

The body of these products is made of polypropylene, so that the installation of cranes is carried out in the same way as the connection of polypropylene pipes and other fittings. Among the features of the device can highlight the ability to pass and the lack of need for maintenance.

To open or shut off the water, the ball rotates 90 degrees around its axis. This is done with the help of a special lever located on top.

Note! The ball valve cannot be used to regulate the flow of water. It must be fully open or closed. Otherwise, the locking mechanism will quickly fail.

As an example, below we give the technical characteristics of a polypropylene ball valve pprc pn20:

| Operating temperature range | 0 -95 degrees Celsius |

| Nominal diameter | 20.63 mm |

| Lifetime | For cold water supply - 50 years For hot (no more than 75 degrees at a working environment temperature) - 25 years |

| Nominal system pressure | 20 bar |

Tip! More detailed information about these devices can be obtained from GOST for polypropylene fittings - 52134-2003.

It must be said that the considered valves due to chemical stability has found application not only in domestic pipelines, but also industrial ones, in particular, they are used in pipelines for acid.

Merits

Among the advantages of valves of this type are the following points:

- Durability;

- Low price, as polypropylene is an inexpensive material;

- The device is compact, has an attractive appearance;

- Scale does not form on the surface;

- Does not require maintenance during operation;

- It has good tightness;

- The ability to install by hand, the only thing you need is a special welding machine.

- Low weight.

Note! When choosing a polypropylene ball valve, you must ensure that its internal diameter in the gate corresponds to the internal diameter of the pipeline.

disadvantages

As for the minuses of this device, there are not many of them:

- As mentioned above, this valves cannot be used for flow control.

- The device cannot be disassembled. Therefore, in the event of its failure, you will have to perform a replacement.

As we see, the shortcomings are not at all critical.

Types of polypropylene ball valves

The main difference of the considered devices, in addition to the diameter, lies in the method of installation.

They are of two types:

- Soldering - used when installing between polypropylene pipes.

- For threaded connection - used in cases where it is necessary to make the valve removable or to make the transition from metal pipes to polypropylene or vice versa. In this case, a ball valve made of polypropylene is threaded on one side and, on the other hand, is soldered.

Thus, the choice depends on the place of installation of the product.

Mounting method

Despite the fact that the installation of polypropylene fittings is not a big deal, before embarking on this work, you should familiarize yourself with some of its nuances.

So, the installation instructions for a polypropylene crane are as follows:

- First you need to turn on the soldering iron and wait until it warms up to operating temperature. A green indicator will indicate heating.

- While the soldering iron is being heated, the pipe should be cleaned (if the pipe is reinforced). For these purposes, a special device is used, which must be worn on the pipe and rotated several times.

- Then you need to insert the pipe and faucet in the nozzle of the soldering iron. This should be done accurately and quickly.

- Next, you should wait until the surface of the connected elements warms up. The instructions for the soldering iron have a table of the heating time of parts of different diameters.

- After heating parts, they should be removed from the tip and connected to each other. In this position, the parts must be held until the plastic hardens, without displacing them relative to each other.

- Then in the same order the opposite side of the crane is connected to the pipeline.

Tip! Before starting installation of valves, you can practice on trimming pipes and cheap fittings.

This process of installation of the crane is completed. As for the threaded connection, it will not cause difficulties, since it is carried out using ordinary cap nuts.

Conclusion

Polypropylene ball valves are important fittings, without which not a single polypropylene water supply system in houses and apartments. The popularity of this valve is primarily related to its reliability, durability and many other positive qualities.

From the video in this article you can get some additional information on this topic.