Polypropylene crane - a modern solution for your

Cranes made of polypropylene cause distrust among many buyers due to the fact that they consider the material to be made unreliable and short-lived. Meanwhile, modern technologies provide the highest quality manufacturing, so that in their properties such cranes are not inferior to metal products, and even surpass them in some indicators. This article will discuss the main features of this type of products and the criteria for selecting quality models.

Advantages of this product group

Valves for polypropylene pipes can be very different: steel, brass or from the same material as the main communications. It is the last option that we will consider in more detail, especially since it has a number of undeniable merits:

| Easy installation | Any expert will confirm that it is much easier to install a polypropylene tap with your own hands than a metal one. The fastening system is a threaded pipe connection and the most important thing is to select the nodes with the desired thread so that you do not have to return to the store again for replacement. |

| Low weight | The mass of structures of this type is much lower than other options. This not only simplifies their loading and transportation, but also reduces the load on the structure, which in some cases is a fundamental factor in choosing |

| Corrosion Resistance | Due to the fact that polypropylene is not subject to corrosion processes, the inner surface of the nodes remains smooth for many years, it does not accumulate plaque and significantly reduces the likelihood of blockages |

| Easy operation | After installing and assembling the system, the cranes do not need maintenance, that is, communications do not need to be periodically checked and cleaned, which is very important in places that are difficult to access for any reason. |

| Durability | The service life of products made of polypropylene is about 50 years, which exceeds the performance of most analogues. At the same time, the price of products is very democratic, which can also be attributed to important advantages. |

Note! Another important advantage is the fact that the locking mechanism is made of high-quality stainless steel, which guarantees the durability of the structure and its resistance to adverse influences.

Features of polypropylene cranes

First you need to deal with the main features of the design, it will allow you to better understand how the system functions.

Device

Products can be made from different types of raw materials, most often the upper limit of heat resistance is limited to 95 degrees. It is best to choose the design of the brand of raw materials PPRC, the size range of products is quite wide, but the most common are sizes 20, 25, 32 and 50 mm, but you can find other options.

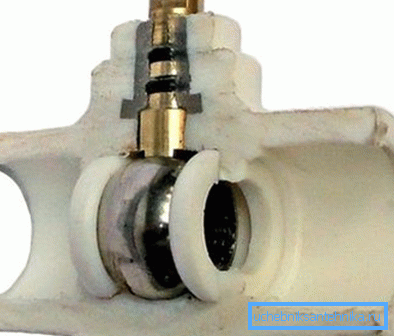

Regardless of the size of the design consists of the following components:

- Body made of the highest strength polypropylene. It is very important that the knot be cast qualitatively, without any flaws and superficial defect.

- The locking element is a ball with a hole for the flow of water. Best of all, if it is made of stainless steel, and the surface is polished with a laser, this ensures the most dense and reliable fit.

- The rod is the axis on which the locking mechanism is mounted, it must be adjusted very precisely to prevent even minimal play.

- O-rings are used to prevent water from penetrating through the stem mounts., They must be made of high quality rubber.

- For a close fit of the ball to the body, two rings are used., which can be used either from Teflon or Teflon.

- Adjustments of the mechanism are carried out using a handle that is attached with a special screw..

Types of products

Depending on the design features, all such products can be divided into several groups.

For example, depending on the type of case, the following options can be distinguished:

- Non-separable options have a solid body, they are easy to operate and cost a little. But the biggest drawback is the fact that in the event of a breakdown, the node is not repaired, but replaced entirely.

- Collapsible cases are more massive and more complicated, but in case of a malfunction, they can be repaired by replacing worn gaskets or entire parts of the system without replacing the entire assembly.

Depending on the direction of flow, the following types exist:

- Straight lines through which the fluid passes in one direction.

- Angular, in which the flow direction is changing, they are most in demand when connecting radiators of the heating system and allow you to do without American couplings.

Tip! Always ask the seller about the quality certificate.

It is also possible to meet designs not only with two exits, but also with three. The second option is much less common, but in places where it is necessary to connect three pipes, it is simply indispensable.

Conclusion

This article is a kind of instruction on the choice of valves from a new generation of materials, it is important to choose a quality option, and it will serve for a very long time. The video in this article will tell some more important nuances on this topic.