Pump stuck in the well: causes, elimination, prevention

What to do if the pump is stuck in the well on the water? It is clear that the optimal solution is the challenge of specialists; However, this work is not cheap, and there is not always an opportunity to coordinate your day off with the time of their visit.

In the article we will examine several typical causes of a malfunction, their self-remediation and preventive measures that will help to avoid problems in the future.

General rules

Let's start with a list of general preventive measures that will help you avoid most of the trouble during the operation of the well.

- Use only braided stainless steel cable with reliable hinges.. Steel cable in a plastic sheath and especially a nylon cable after several years of operation is likely to break under the weight of the pump.

- It is extremely undesirable to splice the cable segments.. Any connection is a potential drop site.

- Select casing diameter with a margin. So, for a 4-inch pump, a reasonable minimum is 125 millimeters. If you are using a 110-mm pipe with a socket connection as a casing, you may prefer to choose a 3-inch borehole pump.

Good to know! With the same performance and head of the product of a smaller diameter is somewhat more expensive. The fact is that the smaller the diameter of the rotor and the stator of the motor, the harder it is to ensure sufficient torque. Reducing the diameter of the impeller also adversely affects performance, forcing to increase the number of stages of a centrifugal pump.

- Do not forget to raise the pump from time to time (every 2 - 3 years). With a small depth of the well (on the sand), its periodic pumping is recommended, which allows to remove sand and silt from the wellbore. For this operation, a special screw pump is used, capable of raising pulp containing up to 50% of sand.

- Diaphragm pump should prefer centrifugal. First of all - in the shallow wells drilled on the sand. The vibration of the diaphragm pump speeds up the silting of the trunk many times.

However, suppose that preventive measures have not yet been taken or have proven to be ineffective. Consider a few typical scenarios.

Cable break

Symptoms

Cable removed. The pump remained in the well.

The reasons

Poor quality of the cable, ineptly made splices, excessive force when trying to lift.

Decision

- Choose slack electrical cable and water pipe.

- Secure them to each other with a hose clamp.

- Gently pull up the tube and cable at the same time. If the pump goes up - do not forget to periodically choose the slack of the cable or pipe. They must rise synchronously: at the same time the load will be distributed evenly, which will reduce the likelihood of breakage.

- If the resistance increases, raise the pump to a slip: slightly lower it and try to repeat the section again. If the effort is made dangerously large - fix the communications with a clamp to the edge of the casing and call the specialists.

Prevention

Do not save on the quality of the cable. Its price against the backdrop of total well costs is ridiculous.

Cable overlap

Symptoms

At the beginning of the lift, the pump stalled. When sagging the cable, it moves down freely.

Cause

Slack cable was wrapped around the case or formed a loop in the gap between the case and the casing.

Decision

- Lower the pump half a meter.

- Choose a slack cable.

- Fix it and the pipe to the cable with hose clamps.

- Continue climbing.

Prevention

The problem will not arise if, even when the pump is lowered, the communication is neatly matched to the cable with plastic clips.

Silting up the sand

Symptoms

The pump stops smoothly when lifting. For further movement in the wellbore requires an excessively large force.

Cause

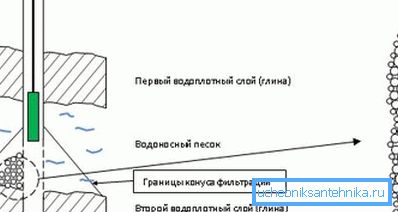

Through the casing filter along with the water, inevitably a large amount of fine suspensions falls into it, settling on the surface of the pump and driving the pipe over it. It is a cork consisting of silt that prevents the rise.

Decision

The pump in this case also increases: the attempts of lifting alternate with lowering by 10–20 centimeters. Gradually, all the sludge is in the bottom of the well. Before re-lowering, the well must be pumped by lowering the pump almost to the bottom of the casing and dropping dirty water onto the relief.

Tip: in this case it is better to use a screw pump designed for lifting water with a large number of suspensions. An alternative option is flushing the well with a large amount of water from the storage tank. Water is pumped to the bottom of the well under high pressure; pulp gushes from the casing.

Prevention

Do not forget about the periodic lifting of the pump and pumping wells.

Casing Liming

Symptoms

When trying to lift a wedge pump in a well drilled on limestone. Resistance does not increase gradually, but increases to the maximum immediately upon reaching the problem area.

Cause

If water is taken from the bottom of the aquifer, it will inevitably stagnate right above the pump. An excess of lime and mineral salts will be deposited on the walls of the casing. The problem is characteristic of steel and asbestos-cement pipes; plastic does not grow.

Solutions

In most cases, this problem can be eliminated with your own hands.

- Perhaps in this case it will be possible to raise the pump vkaskachku, repeatedly raising and lowering it. Limescale deposits are much harder than sludge, but they are still destroyed by mechanical action.

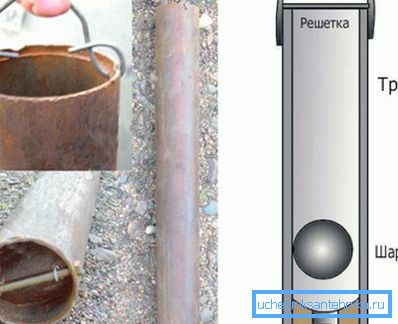

- It often helps to clean the barrel with a slug - a massive pipe with a serrated lower edge and a diameter slightly smaller than that of a casing string. A cable, cable and standpipe are passed through the core, after which it smoothly descends on its own cable until it sags. The pump must be completely lowered, the slack of all communications is etched. Repeated lifting and lowering the shells will help to remove deposits from the walls of the well.

Prevention

- Periodic cleaning of the well with the same scab will prevent the formation of deposits that can significantly narrow the wellbore.

- It is better to place the pump in the upper part of the aquifer. How to find out. where does it start? The obvious instruction is to monitor the composition of the soil at the drilling stage and at the time of reaching the sand layer measure the height of the drill string.

Conclusion

What to do if all these measures did not help? Alas - just contact the experts. Cleaning the barrel and lifting the pump is much cheaper than new drilling.

As always, the video in this article will offer the reader more information. Successes!