Pump to the well: how to correctly select the unit

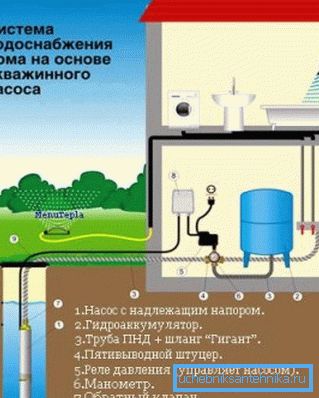

After the well is drilled at the site, it must be equipped with a pump. Only a properly selected quality product will guarantee a trouble-free water supply to your cottage or country house.

Buying a pump in the well, you need to take into account many important points.

Main selection criteria

Before you choose the type and specific model of the unit, consider a few key factors.

Water level and well depth

When you do not know exactly the parameters, they need to be measured.

- For this purpose, pull dry twine into the barrel with a weight attached to it.

- On the wet rope mark, you will calculate the distance to the liquid. Measuring, wet area, find out the height of the water column in the bottom.

- These values will be the main choice. Usually, the instruction prescribes to indicate them in the technical passport of the pump.

- On this basis, when purchasing an aggregate, please note that a specific model of the device works for a long time and without interruptions only in the specified range.

Object debit

This value indicates the volume of liquid that a water intake point is able to produce in a certain time.

- To measure exactly this parameter is almost impossible. As a consequence, it will be sufficient to determine it approximately.

- To this end, lower the pump into the well bore and determine the time during which it will pump out water.

- Check the time period for which the water column is fully restored.

- Next, divide the second digit by the first.

Bore diameter

- If you were drilled by experts, find out the section of the trunk from them. However, measurements can be carried out on their own, there is nothing complicated about it.

- As a rule, specialty stores sell borehole pumps for 3 inches and 4. It should be remembered that an inch is 2.54 cm.

- If your face will have a diameter of 4 inches, problems with the acquisition of the unit will not arise - such objects are standard.

Note! Three inch well pumps are not as common. It may be that in your city you will not find such a device. We'll have to order it anywhere else. Therefore, when you have a choice, it is better to drill a well four inches in diameter.

Water flow

- Before purchasing a unit of a specific model, determine your water need. This circumstance is the most important for the choice of pump motor power.

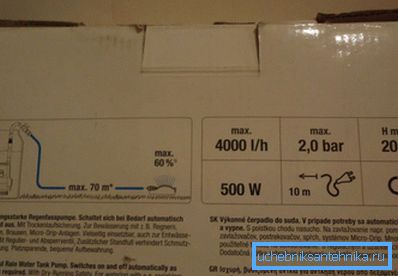

- It should be noted that borehole pumps can pump out 20/200 l / min.

- Usually, for an average family of 4 people, it is enough to buy a device with an engine with a capacity of 50/60 l / min.

- If your family is large, or you plan to water the garden / garden, then buy a pump that has a capacity 2/3 times higher. Of course, its price will be quite high.

The pressure that can give the pump

Calculate this parameter fairly easily.

- For this purpose, it is necessary to add 30 to the depth of the trunk (in meters).

- For safety net, add 10% to this figure.

- For example, the depth of the wellbore is 40 meters. 40 + 30 = 70 + 10% = 77.

- Of the various pump models, the best option is to choose a device that is capable of delivering a head of 90 meters.

Unit cost

The cost of the device consists of many points.

- Any of the pumps before immersion is suspended on a stainless steel cable. This material must be of high quality, which increases its price.

- It is best to connect the water supply through the machine, which will turn on and off the pump, as needed. It is also necessary to install a ROM (start-up device) or purchase a unit with an already mounted device. This will ensure smooth start-up of the well pump. These devices will increase the cost of the system.

- An inexpensive pump can have almost the same characteristics as an elite model. However, any defect in any unit of the unit can completely disable it.

- Connections under water are quite vulnerable. Usually, high-quality soldering is only for relatively expensive devices.

Note! Do not save on the pump. Emergency repair will take more money from you than you save when you purchase the unit. In addition, during the repair the entire area will remain without water.

Contamination level of the well

Many wells are not equipped perfectly, or have already served for a long time. On this basis, the pump will be regularly clogged with sand, silt, etc..

Constantly raising to the surface and cleaning the device is quite expensive. Therefore, it is best to immediately choose not just a submersible model, but designed specifically for operation in the well.

Types of pumps

Now about what you can install the pumps on the well.

Surface analogs

Such devices are removed from the fluid being pumped. As a rule, their hull is located on land. However, some types of aggregates have special floats. Such small devices can be located on the surface of the water.

This type of units can be used if the well water supply uses a storage tank or water tower. They are also suitable when the well is being pumped.

When choosing such a device, the main parameter is the level of its operation. Usually, surface mechanisms work effectively at a depth of no more than 7/8 m. To increase this parameter, it is necessary to modernize them. This reduces the reliability of the system and increases its cost.

Based on the above, it is advisable to use surface pumps at shallow depths.

Submersible (deep) devices

By design, such units are divided into vibration and centrifugal analogues. Despite this, any depth device is partially or completely immersed in the fluid it pumps.

Note! The greater the depth of the source of water intake, the better it is to use this type of unit. It should be noted that conventional submersible pumps can operate, as much as possible, at a level of -10 m. Therefore, for deep bottoms it is necessary to choose special pumps, which are called “borehole” ones.

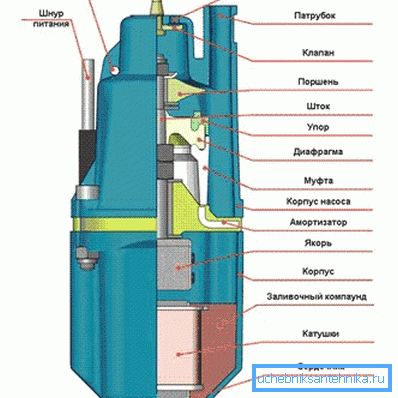

About some features of vibration mechanisms.

- Their main structural element is a membrane.

- There is water on one of its sides, and a vibrator at the opposite end, which causes the membrane to deform.

- In this case, a pressure differential appears, thanks to which water is pumped over.

- It is best to choose a model that is equipped with a thermal relay turning on the pump well. In addition, the unit must take the liquid in its lower part.

- If the soil is clay, such an aggregate should be located as far as possible. Otherwise, it will gradually destroy the walls of the well. This will require pumping out turbid water, otherwise the well will be clogged.

- When such a mechanism is buried in sand or silt, it should only be pulled out when it is turned on.

- The cost of vibration mechanisms is relatively low, but the reliability of their operation is not high enough.

A little bit about centrifugal pumps.

- The basis of their working mechanics are one or several wheels. They are fixed on the central shaft and equipped with blades.

- When operating the unit, the gaps between the blades are filled with water.

- When rotating, the blades form a centrifugal force. It creates a pressure differential, thanks to him the unit and pumps water.

At the moment, this type of pump is the most in demand, because has the best value for money. In addition, centrifugal units are universal.

Manual units

There are cases when the site is not connected to the mains or finances do not allow to install a modern system. Then the well can be operated using a manual pump.

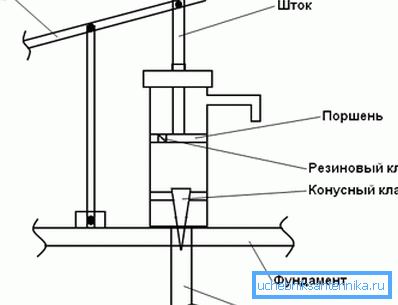

Such devices are piston or rod.

- The first units can operate at a depth of no more than 7 m. Their design is based on the interaction of two valves that are in the cylinder with a piston placed in it. The movement of the piston generates a vacuum and the liquid rises. At the same time, one of the valves (suction) opens, the second closes.

- Rod analogs are designed for deeper points of water intake. The pump cylinder is lowered over the entire length of the wellbore, the column is mounted from the pipes and the fluid is pumped using a check valve.

- The advantages of hand pumps are independence from electricity, low cost and ease of operation. The main drawback, with the need for water - this problem has to be addressed directly, while applying physical effort.

How to pick up pipes

Often the weakest link in the water supply system is the pipeline.

Even if you pick a high-quality pump and choose the right model for it, this part of the system can let you down.

- At present, plastic pipes made of special polypropylene are considered to be the best products for laying the external plumbing.

- Such material will meet all requirements for specifications.

- The mass of such products is much less than metal counterparts. Therefore, it is easier to deliver and assemble them.

- The strength and reliability of plastic pipe joints is higher than that of metal pipes.

There is one limitation in the use of this material - it is the pressure in the system. It should not exceed that indicated by the manufacturer of the pipe.

Note! Problems and work in conditions of negative temperatures. In this case, some types of plastic become brittle. If you put two pumps in one well - one of them is of the submersible type (in the bottomhole), the other is for a storage tank located in the “pump”, for the second unit you can safely collect plastic water supply.

The nuances of mounting the pump

For normal operation of the water supply you need to know how to properly place the pump in the well.

Important points

- Buy a plastic hose with a cross section of 2 cm. To determine how many meters it is needed, measure the depth of water raising / lowering.

- Usually pumps are hung on metal wire or cable. However, there is one important nuance here - now many of the models of the units have aluminum cases. During operation, the mechanism vibrates; as a result, at the site of its connection with the suspension, the body is deformed. This may damage the unit.

- Therefore, the best option is to use a cord from nylon. It is moisture resistant and very durable. It is necessary to acquire a cord of the cross section that can withstand a weight that is 5 times larger than the weight of the pump.

- To dampen excessive vibration at shallow depths, when a well is being constructed with your own hands using a pump, install a springy suspension on it. It is possible to make it yourself from a rubber braid. One side of the fixture is mounted on the pump, and the other is fixed on the crossbar.

- When lowering the unit, to the bottom of the bottom must remain more than 30 cm.

- The pump should not touch the walls of the barrel.

Surface mounting

- To automate the operation of the well, put a water level sensor in the storage tank.

- The most common float devices, their contacts are located in the coil of the command relay.

- Elements of automation choose, based on the power of the pump and the number of phases of its motor.

Submersible analog connection

- This unit controls the electronic unit. It is mounted in a convenient place to access.

- The power wire should have a waterproof braid and be connected to the unit with a sealed plug, equipped with an electrode for grounding.

- It is necessary to put a device for differential protection, as well as a three-pole circuit breaker, in the power panel of the electric motor.

Conclusion

How well you choose the pump for your well will determine the efficiency of its operation and the duration of its operation. Therefore, be especially attentive to this issue. When you get acquainted with the video in this article, you will get a lot of additional knowledge.