Pumps for water supply from a well: let's organize

How to organize a permanent water supply of a country house with a well as a water source? What elements should include plumbing? What are the signs to choose a submersible pump? Let's try to answer these questions.

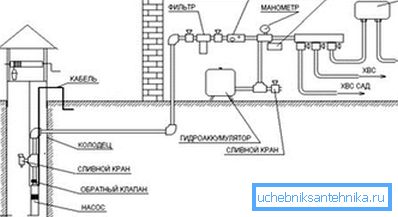

Scheme

Items

Let's start with a list of basic elements that should include the simplest scheme of water supply from a well with a submersible pump.

- Actually pump, lifting water from the bottom of the well and providing excess pressure in the water supply system.

To clarify: surface pumps, in principle, can also be used to organize the suburban water supply; however, the depth at which they can lift the water is limited at best to 7-8 meters. The reason lies in the fundamental laws of physics. The absolute vacuum in the pipe is capable of raising the water column by 10 meters at atmospheric pressure; a real pump creates a much lower vacuum.

- Check valve at the outlet of the pump. It will not allow the water that has filled the pipe to flow back into the well.

- Hydroaccumulator - tank with elastic rubber membrane separating the water and air compartments. This device is able to accumulate a certain amount of water while simultaneously creating an overpressure in the circuit. The greater the volume of the accumulator, the less often the pump will turn on during daily use of the water supply system.

- Pressure sensor and relay controlling pump power.

Instead of a hydroaccumulator and pressure sensor, you can use a storage tank with a water level sensor raised to the attic of the house or to a natural elevation.

Capacity allows you to stock more water; However, this solution is not without flaws.

- Typical for a country house wooden beam overlap is not designed for a load of several hundred kilograms created by the tank.

- The head in the circuit will be limited by the height of the tank above the water tapping point (usually 2.5 - 5 meters). This is just enough to ensure that the mixers with aerators and toilet cisterns work. The intake valves of washing machines, pressure sensors of instantaneous water heaters and some other devices are capable of operating at an overpressure of at least 0.3-0.6 kgf / cm2.

- A large supply of water at a small water draw will mean that the water will begin to stagnate. In the well, it is continuously updated due to the migration of groundwater; in the same tank may well begin to bloom.

Pipes

The optimal solution for laying the water supply system from the well to the house is a polyethylene pipe at compression fittings. Arguments?

You are welcome.

- Polyethylene is not afraid of displacement and movement of the soil: it is elastic.

- Elasticity is maintained at negative temperatures. If water freezes in the pipe, the ice plug will not break it, but only expand it a little. After thawing plumbing will return to its original size.

- The installation does not require any tools other than a miter knife. All fittings are assembled by hand.

Installation rules

There are not too many rules to follow when building an autonomous water supply system with your own hands.

- Both the pipe between the house and the well, and the entry into the well must be below the level of soil freezing.

Tip: where for some reason this is not possible, the pipeline is packaged in a heat-insulating shell with a self-regulating heating cable inserted into it.

- At the lower point of the pipeline it is desirable to provide a waste valve for its complete drainage. The instruction is relevant first of all for those houses that are not heated round winter.

- The well is closed from debris and insulated to avoid freezing.

The pressure sensor is calibrated so that the pump starts at a pressure of H / 10 + 1 kgf / cm2. The height of the upper point of the water supply system relative to the sensor in meters is taken for H. The pump off pressure is 1.5-2 kgf / cm2 more.

The pump is hung at a distance of about a meter from the bottom of the well. In this case, it will not suck silt and sand.

A bottom filter with several layers of sand and rubble is arranged at the bottom of the well. The muddy bottom is additionally covered with a board shield. For its construction it is better to use rotting larch.

Pump selection

What should be the submersible pump in the well for water supply?

To begin with, we will formulate the tasks facing the pump.

- It should require minimal maintenance and have a maximum overhaul time.

- He will transport pure water with a minimum amount of suspended matter.

We now turn to the types of pumps. There are only three of them in the market sector that interests us.

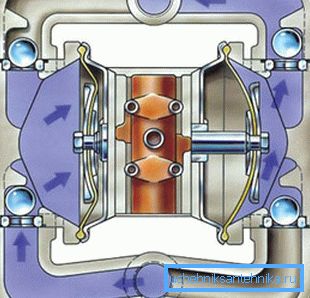

Membrane (vibration)

At the heart of its design is a working chamber with a pair of check valves, a solenoid with a spring-loaded ferromagnetic core, and one or two elastic membranes.

How does this scheme work?

- The solenoid is powered.

- The inductance generates an electromagnetic field that drives the core together with a membrane attached to it. The membrane creates excessive pressure in the working chamber; excess water is forced into the outlet through an open check valve. The second valve - closed - blocks the displacement of water in the inlet pipe.

- After power is removed from the solenoid, the spring returns it to its original position. In this case, the position of the check valves is reversed, so that water is taken not from the outlet, but from the inlet pipe.

- The cycle is repeated.

The main advantage of the vibration pump is the low price with moderate performance and good head. We present the characteristics of a membrane streamlet that is very common in the post-Soviet space.

| Parameter | Value |

| Maximum head | 60 meters |

| Productivity at a pressure of 40 meters | 432 liters per hour |

| Overall dimensions (diameter x height) | 98 x 268 mm |

| Retail value | 1300 rubles |

The bad news is that for our purposes this device, like all diaphragm pumps, is absolutely not suitable.

- Overhaul resource is limited to one to two years. Elastic membranes are mechanically deformed in each work cycle; with a frequency of vibration of about 100 hertz, it is not surprising that after some time they require replacement.

- Vibration leads to accelerated silting of the well.

- Finally, a capacity of 400 liters per hour can be sufficient only with a minimum amount of water and a very capacious accumulator.

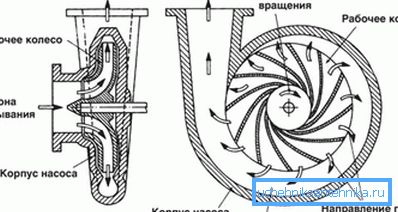

Vortex

The basis of the vortex pump is a centrifugal impeller with a minimum gap between it and the cochlea (pump casing). When the impeller rotates at its periphery, a significant overpressure is created; along the axis, respectively, a rarefaction occurs. It is enough to connect the inlet and outlet nozzles at the corresponding points of the casing in order to organize a stable and fast pumping of water.

Swirl scheme:

- Provides high performance at high values of pressure and modest pump dimensions.

Important: in the case of a well, dimensions - height and diameter for a potential buyer are not crucial.

- Make the device extremely sensitive to the amount and size of impurities. The norm for a vortex pump is no more than 30 grams of suspensions per cubic meter of water. Exceeding this amount leads to accelerated wear of mechanics with a concomitant drop in head and performance.

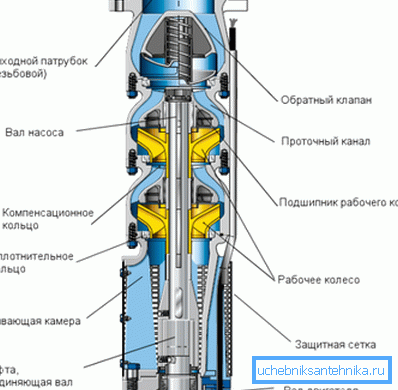

Multistage centrifugal

Initially, the centrifugal multistage scheme of the pump was developed for wells: it is problematic in them to get a large head output due to the limited diameter. However, it will be the best solution for the well.

The basic idea is that on one shaft rotated by a single electric motor, there are several impellers. Between them and the body remains a fairly large gap, which makes the device insensitive to a large number of suspensions.

The attendant problem — the inevitable drop in pressure — was solved simply and gracefully: the chambers (diffusers) of all the impellers are connected in series with the moves in the housing. As a result, the head generated by all the impellers are summed minus the small losses on the hydraulic resistance of the pump itself.

Head and Performance

The pump head should be 30 meters greater than the height difference between it and the top of the water supply system. So, if the pump is immersed at 12 meters, and the top of the water supply taps in the house is located 4 meters above the ground level, you should buy a device with a nominal pressure of 12 + 4 + 30 = 46 m.

Performance in liters per minute is roughly calculated at the rate of 5 liters per person. So, for a family of three, it will be 3 * 5 = 15 l / min, or 0.9 m3 / hour.

Recall: with an increase in the capacity of the hydroaccumulator, the requirements for pump performance can be significantly reduced.

Conclusion

We hope that our recommendations will be able to help the reader in the design and construction of their own autonomous water supply system. The video in this article, as always, contains additional material. Successes!