Pumps for wells: features of choice and operation

At the moment, pumps for wells on the market are presented in a wide range. On the one hand, this is good, as there are plenty to choose from. On the other hand, an inexperienced buyer may have difficulty acquiring the modification that will correspond to the parameters of the well.

So, what pumps for a well today can be purchased and what to look for when choosing one or another modification?

Criteria for the selection of water intake devices for wells and boreholes

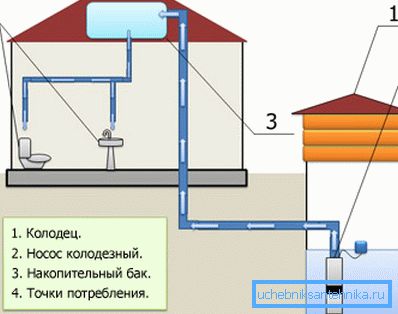

When choosing a pump for irrigation from a well, first of all, you need to take into account such a parameter as the distance from the tip to the water-filled part of the barrel. If this distance does not exceed 8 meters, it is advisable to choose a self-priming intake device. If the surface of the water is more than 9 meters, a submersible (deep) pump to the well is a reasonable option.

The next most important selection criteria are device performance and maximum head height. These parameters are indicated in the accompanying documentation and must necessarily be compared with the magnitude of the water flow and pressure in the water supply system.

Another parameter that needs to be taken into account is the distance from the water intake shaft to the house. When choosing equipment, this value should be compared with the parameters of hydraulic resistance in the pipeline.

In order to compensate for hydraulic losses, it will be necessary to select pumping equipment with a power reserve of more than 10%.

Varieties of well and borehole pumps

Surface self-priming pumps into the well are single or multi-stage devices designed to lift water from the intake shaft and feed it to an autonomous water supply system.

Multistage modifications differ from single-stage counterparts with lower power consumption and low noise with similar performance and head parameters.

Among self-priming surface pumps there are modifications, both with built-in ejector and without it. This is an important feature that must be considered when choosing.

Equipment with an ejector pumps water by discharging. Among the advantages of this solution, we note the economical power consumption and low equipment wear. However, there is a drawback, namely a high noise level during operation. For this reason, equipment of this type should be located in a specially built, isolated room.

A surface pump for wells without an ejector supplies water through a multi-stage hydraulic mechanism. As a result, the work of such equipment is virtually silent.

A fundamentally important characteristic when choosing a surface pump is the nominal flow, which is measured by the number of cubic meters per hour. Surface pumps designed for domestic use, as a rule, provide flow from 4 to 8 m3 / h with a maximum pressure of up to 55 m.

Important: for efficient operation of the surface pump, a check valve must be installed on the suction pipe. Such a measure will allow to save water in the system when the pump is off.

Submersible or submersible pumps are universal equipment that is suitable for use in most wells and boreholes. A feature of the operation of such facilities is complete immersion in water. Therefore, it is necessary to monitor its location during seasonal drops in water level.

If the device works in an underloaded condition, the engine will most likely overheat and the winding will burn. As a result, you have to fork out to buy a new engine or to purchase a new pump.

To simplify the operation of the autonomous water supply system and not to look for the best well for the pump, purchase devices equipped with a special float. The float switch automatically stops the engine when the water level in the wellbore drops below the limit.

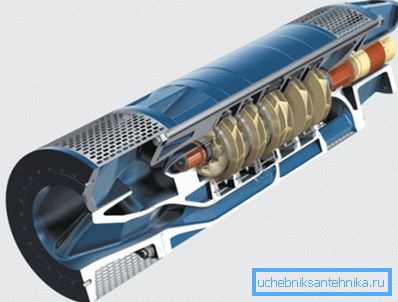

Submersible pump for a well of 12 meters or more, in accordance with the principle of operation, can be centrifugal or vibration.

- Centrifugal immersion modifications are characterized by intensive feed. But, the consequence of high performance is the high price.

Such devices are the optimal solution for old wells and boreholes. The fact is that the equipment of the centrifugal type, in contrast to the vibration analog, does not exert pressure on the walls of the trunk.

- Vibrating submersible pump for a well of 20 meters differs from centrifugal plants at lower cost and more modest performance parameters.

This type of equipment is not appropriate for operation in wells. Since the diameter of the barrel is small, the use of the pump will contribute to the soiling of the well and will have a decrease in flow rate (decrease in the intensity of water flow).

Submersible units can be equipped with upper or lower water intake, that is, the location of the suction valves can be upper or lower.

Both options have obvious advantages and disadvantages. For example, the presence of the upper fence makes the equipment more protected from the ingress of clay or sand from the bottom of the well. On the other hand, such a construction solution makes the equipment more vulnerable in the event of a decrease in the water level.

Submersible pumps are usually classified according to the number of valves. There are one-valve modifications, which are the most common. There are also two-valve devices that are more powerful.

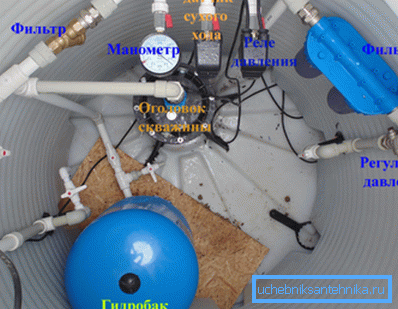

Features of the installation of submersible pumps

- At the initial stage, we select a pipe through which water will rise from the well. The instruction allows the use of both rigid and flexible plastic pipes, but certainly with reinforcement, so that over time there is no need to carry out repairs.

- Next, we prepare a special cable for connecting a submersible pump for the well. The cable differs from the ordinary wire by the presence of three conductors for three-phase connection and a hydrophobic sheath. The sheath of a special cable does not lose its original performance even with long-term operation under water.

- In addition to the pipe and cable, you will need a special cable with which you can lower and lift the device from the water intake shaft. The special feature of the cable is not only that it is strong, but also that it is not susceptible to corrosive effects.

- The submersible pump, by means of adapters and fixing clamps, we connect with our own hands to the pipe through which water flows into the pipeline.

- Further, in accordance with the instructions, connect the power cable. At this stage, it is important to follow the manufacturer’s recommendations as precisely as possible in order to eliminate the possibility of a short circuit during operation.

- Approximately 3 meters above the pump we install a check valve, the diameter of which must correspond to the diameter of the pipe cross section in order not to create excessive hydraulic resistance.

Important: In order to properly install the check valve, pay attention to the arrow marked on the body. The direction of the arrow indicates the direction of water flow.

The fundamental differences of the downhole submersible pump from the well

Centrifugal pumps designed for pumping water from wells, have a number of fundamental differences from the equipment intended for use in the well. Consider the most significant differences.

Centrifugal well equipment, in contrast to well modifications, is equipped with an engine cooling jacket. This difference can be determined by the increased diameter of the device.

As a result, pumps are characterized by increased productivity, but at the expense of larger diameter can only be placed in wells or in large wells.

Downhole pumps are not equipped with an engine cooling jacket, since the cooling process is carried out due to the flow of raised water. This solution allows the use of the device in wells with a small bore diameter.

When selecting the parameters of the downhole pump is taken into account:

- distance from the bottom of the well to the upper level of the water rise;

- distance from the top of the wellbore to the water level;

- the amount of pressure required for the full operation of the water supply system (most often this value should be up to 3 atmospheres, which corresponds to 30 meters of water column);

- pressure loss in the pipeline from water intake to the consumer.

Speaking about the characteristic differences between well equipment and well equipment, we note that pumps for wells imply the need for stable voltage (differences of no more than 5% and less).

Again, these devices must necessarily be completed with such auxiliary elements as protection against dry running and non-return valve. Well pumps can also be retrofitted with various safety devices, but if necessary, they also work in stock configuration.

The choice of equipment in accordance with the brand

At the moment, the main range of submersible and surface pumps on the market is represented by products of European and Chinese manufacturers. European products of such brands as Calpeda, Grundfos, Pedrollo, Wilo, etc., demonstrate a cost much higher than the price of Chinese analogues. But the resource operation of such equipment is much longer.

Conclusion

No matter what you get, drainage pumps for wells or a device for water supply at home, you need to choose such equipment correctly, taking into account parameters that can affect the efficiency of operation.

More useful and interesting information you can find by watching the video in this article.