Pumps for wells: types and selection criteria

Modern private housing is difficult to imagine without a plumbing. Due to the additional conveniences, most of the site owners prefer an autonomous water supply system, which cannot be done without a well. But in order for an independent water supply system to function normally, only drilling operations will not be enough, since water pumps for wells are also an indispensable and significant component of the entire similar system.

If earlier many owners of country sites were puzzled with the question of how to make a pump for a well with their own hands, now this problem is very easy to solve, since now such units can be easily purchased at any specialized outlet. However, since the choice of manufacturers and models is huge, an ignorant person is likely to get confused in the proposed range.

That is why, before you make a purchase, which, by the way, you should think already at the stage of completion of drilling, you will need not only to find out how much a pump costs for a well, but also to learn what parameters need to choose such equipment and what types it is.

So, what should a private landowner know in order to ensure that water pumps for wells provide his house and land with water for many years without interruption?

Types of water pumps for wells and their features

Conventionally, all types of pumps for extracting water from wells are divided into submersible and surface. Each option has its own purpose, so in order to correctly choose the optimal model and not spend money on the wrong equipment, let's take a closer look at the features of each individual type.

Submersible pumps

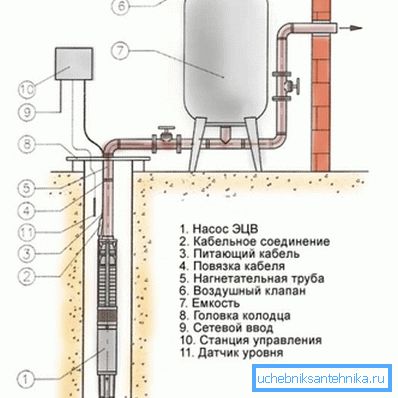

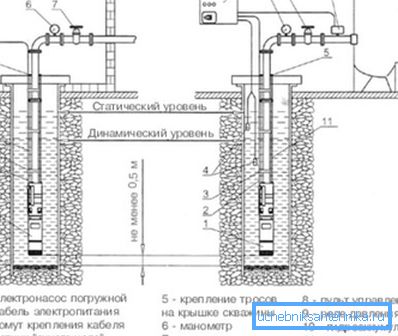

This type of equipment does not have an alternative in cases where the aquifer in any area lies at a depth exceeding 10 m. It is intended either for full or partial immersion in water.

And since water is considered to be an aggressive medium, therefore, of what material the body of such a pump is made of, is of paramount importance. In order for equipment to last longer or not fail prematurely, it is better if it is made of stainless steel.

Note! In no case should the submersible type of equipment on air be switched on, even for a short time. This is explained by the fact that the device protected by automatic equipment is usually built into the pump device for a well of this category, which, when using equipment in an environment not intended for it, simply refuses to function. Moreover, such a device may even burn out, causing the unit to break.

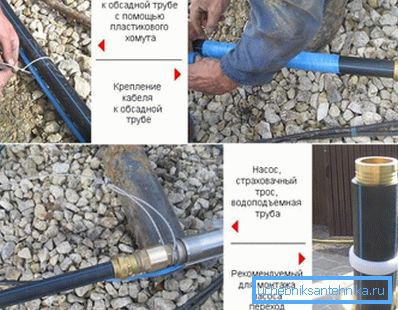

When buying a submersible pump, be sure to immediately take care of the cable, which is necessary for fixing the pump. His choice is a very important point, because the cable for the well pump must withstand not only the weight of the unit itself, but also the mass of the pipe filled with water.

If the cable is chosen incorrectly, it can break, and this will lead to the fact that you will have to purchase a new pump. For this reason, despite the fact that the price of cables intended for these purposes is not cheap, experts do not recommend saving them.

The most affordable include cables made of artificial materials such as nylon or nylon. They are not subject to the formation of rust, but they tend to stretch over time.

A more reliable and durable alternative are stainless steel cables, but their cost is significantly more expensive than other similar options. Also for these purposes, instead of cables, you can use alpine ropes or chains with small links.

The cost of a pump for a well of this type is directly determined not only by the properties of the material from which the casing is made, but also depends on the presence / absence of automatic control devices, as well as on the principle of operation.

So, according to the last criterion, the submersible equipment is divided into 2 types: centrifugal and vibration pumps. Each of them also has its own characteristics.

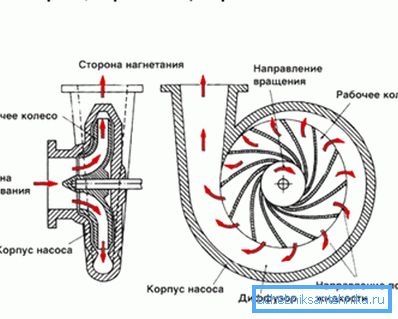

Centrifugal equipment

Centrifugal units are among the most modern and expensive types of submersible pumps. Their advantage is that they can be used both for wells located on sandy soils and for artillery wells.

Such pumps are even able to withstand the transportation of oily or acidic liquids, so few will doubt their reliability and power. If, for example, large areas need to be irrigated at a site, then such pumps for watering from a well are the best solution, since they can provide the necessary pressure without problems and, if necessary, lift large amounts of water from a well in a short period.

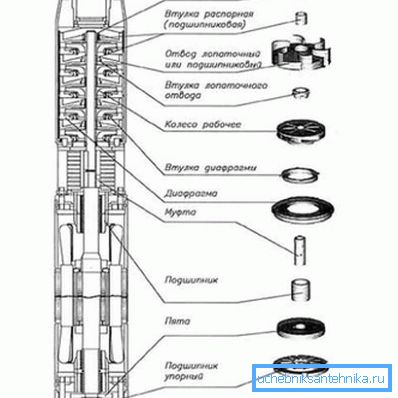

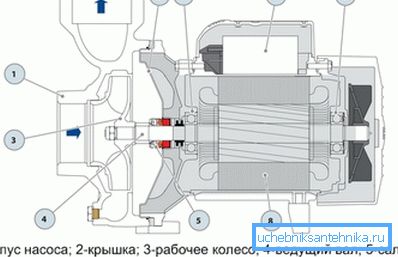

All this is achieved thanks to the special design of the centrifugal equipment. There are single-stage and multi-stage pumps. The device of the first type includes a motor with a shaft on which a wheel is placed, consisting of 2 plates and interconnected blades.

In multi-stage versions, several impellers are installed on the shaft, due to which the capacity of the unit is increased several times. In a word, giving preference to such equipment, each site owner will be able to easily select the optimal pump model that will be able to supply the necessary pressure, since the power range of this type is quite wide.

Note! When choosing a centrifugal pump, it is better to give preference to the device not with stuffing packing, but with mechanical seal, because, in addition to improved performance properties, this will eliminate the need for regular maintenance of the unit.

Usually, the instruction attached to one or another model contains information about what kind of compactor it has, so anyone who does not even understand these questions can learn about it.

Vibration Equipment

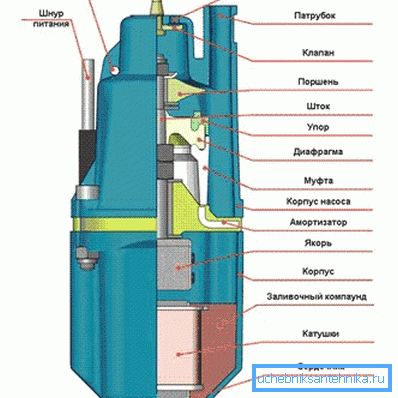

This type of equipment can be used exclusively for sand wells, since such pumps are capable of transporting water only from a depth not exceeding 50 m. These units differ from the previous type by a simple construction device, therefore, their capacity is not that large.

The principle of operation of the vibration units is the passage of electric current through the coil winding. In this case, the resulting magnetic field attracts the existing steel core, and then the rod, to which the rubber diaphragm is attached. Owing to all this, its bending occurs, due to which, in turn, the volume of the chamber increases.

Then water, rushing into the zone of reduced pressure, fills the chamber. After the magnetic field stops its action, the springs begin to bend the membrane in the opposite direction, due to which water is pushed out through the outlet pipe. In other words, such pumps do not contain any complicated and expensive devices, therefore their price is rather democratic.

Deep well pump

Deep-well pumps for artesian wells with a large depth indicator and narrow width are indispensable equipment in hydrogeology, since at sufficiently high power they have rather compact dimensions. To achieve such characteristics, developers and manufacturers of such equipment had to use complex technical solutions in the design of such units, which they cost a lot.

As for the external characteristics, the depth unit is a cylinder with an elongated shape. Its length can vary from half a meter to 2.5 m, and its diameter is up to 10 cm. Since such pumps are expensive, you need special equipment, skills and knowledge for their installation, you should never try to install them with your own hands.

Sump pump

This type of equipment is also designed for deep wells, however, unlike the previous version, such pumps have a larger diameter. In addition, the depth of immersion they have an order of magnitude less.

Their main advantage is the ability to pump contaminated liquids. This option is indispensable when the water from a well or a reservoir is planned to be used not for drinking, but exclusively for irrigation.

Surface pumps

These pumps differ from submersible ones in that their capacity is designed to lift water exclusively from shallow wells (no more than 10 m). Also, their peculiarity is that such aggregates can function only on the surface. In other words, during installation of the equipment, the pump is installed on the ground, and the hose itself is lowered directly into the well, which must necessarily have a check valve.

Note! Do not use a rubber hose for the surface pump. This is explained by the fact that in the process of transporting water, rarefied air begins to form on its inner walls, as a result of which the hose is compressed, thereby blocking the passage.

Since the engine at the surface units is practically unprotected from moisture ingress (it can burn from its impact), it is very important to take care of this when using such equipment. To protect the pump from moisture, you can place it either under a canopy or build a pit for it.

Also, when operating such equipment, be sure to ensure that the engine always functions under load. Moreover, if there is no water in the pump, it will be impossible to achieve this, therefore in this case it will need to be added manually.

Criteria for the selection of water pumps for wells

When choosing pumping equipment for wells, experts recommend guided by the following criteria:

- Well depth indicator. This selection criterion is key because each model is designed for a specific height of the water column.

- Potential water consumption. This parameter is necessarily taken into account when buying a pump, since the need for water in each case is different. For example, if we take into account the fact that water consumption per person per day averages 200 liters, then for a family consisting of about 4 members, it will be enough to use a pump with a capacity of 40-50 l / min.

Of course, in order to irrigate the site, it will be necessary to purchase a more powerful pump, and here everything will depend on the area that is planned to be watered.

- Well flow rate It is impossible to calculate this parameter with accuracy, however, in order to choose a pump, it will be enough to have approximate data. To obtain them, simple calculations should be made: first, the time at which the well is fully exhausted is determined, and then filled with water.

After that, the second digit is divided by the first number. The result will be equal to the desired debit of the well.

- Head pressure It is impossible to make the right choice of a pump of a particular model without taking this aspect into account. To calculate this value, add the number 30 to the meter depth of the well.

Similarly, it turns out to calculate the value of the water column. As a rule, then the resulting figure is increased by 10% and, based on the result, the pump is selected with the desired pressure.

- Borehole diameter These data are also important when choosing the power of the equipment. Typically, such data are available in the documentation, which is issued by the company after the completion of drilling operations.

- Price. Of course, the possibilities of all people are different, so everything will depend on the preference of the owner of the site. However, it should be noted that saving on submersible equipment should not be, since high-quality soldering at the most vulnerable places is done only by well-known manufacturers who do not have cheap pumps.

Note! To organize the autonomous water supply of a private house, metal pipes have not already been given. The best option for this is a pipe for a polypropylene or polyethylene well pump. At the same time pipes are chosen low pressure.

Conclusion

If you still do not understand which pumps for wells are best to use for a given case, then watch the video in this article. It will definitely help you learn more about this topic and introduce you to additional information regarding the choice of pumping equipment.