Pvc casing for wells - how good they are

Currently, plastic pipes are experiencing the peak of their popularity. Before their appearance on the market, exclusively steel or asbestos-cement pipes were used, now more than half of the owners prefer plastic.

What is the secret of such popularity, are they really so universal, how to mount them properly with their own hands - we will tell about it in this article.

Briefly about the pipes

- Pipes are made of PVC polyvinyl chloride. But for industrial applications and geological exploration needs they produce an improved version of a pipe made of unplasticized polyvinylchloride. Traditionally, products are available in blue.

- Also, their distinguishing feature is that all pipes are already manufactured with a thread for a reliable, tight connection. The thread is located at both ends and fits on the principle of "papa-mama". Trapezoidal thread.

- Due to its ease of manufacture, this product has a wide range. In diameter, ranging from 80 mm to 225 mm, as far as wall thickness is concerned, pipes are selected depending on the depth of the well, from 7 mm for shallow depths and up to 20 mm for deep installation.

Important: the quality of the product is indicated by the fact that the pipes are produced according to strictly regulated parameters. Therefore, acquiring them, pay attention to the certificate, there should mean that they are issued in accordance with GOST TU 2248-001-84300500-2009.

What are these pipes good for?

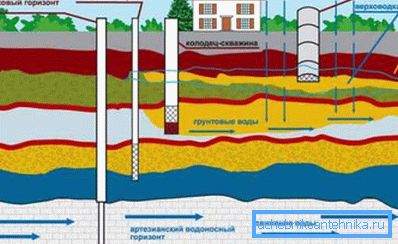

The PVC casing for wells is initially mounted in order to strengthen the walls of the well, prevent soil collapse and protect against minor formation movements.

The product copes with these tasks due to the following qualities.

- NPVH plastic is absolutely neutral material, it does not react with chemically active liquids and minerals, moreover, it easily withstands long-term exposure even with dilute acids.

- Pipes are completely environmentally neutral, they are not subject to corrosion, water in contact with such plastic does not acquire a characteristic taste or smell.

- According to the manufacturer temperature characteristics in the range of -60? C, to +80? C allows you to use these products in almost any climate zone.

- The specified warranty period of operation, 50 years, fully corresponds to reality. Unless of course there are no earthquakes, then this material will stand for 100 years without changing its characteristics. For your information: a thin plastic bottle dissolves in the earth in 300 - 500 years.

- The price of products is incommensurably lower than that of competitors, so even the cheapest steel or asbestos-cement pipes will cost more than the most expensive plastic.

- With the same capacity, plastic products have a smaller diameter, compared with steel or asbestos-cement analogues, which can significantly increase the speed of drilling operations.

- With high strength, the pipes have a fairly small mass, and this makes it possible for even an amateur to work with them when setting up wells in a private house or at a summer cottage. Plus, the material is heavier than water, which is why the pipes are not squeezed out of the soil.

- A threaded joint, at the joints, does not change the internal diameter of the column, in contrast to the coupling. What allows to use much more types of pumps. (See also the article Which Pump is Better for a Well and How to Choose It Yourself.)

- And finally, the price of the installation work on the casing string made of PVC-U, incommensurately lower than that of counterparts.

Important: let's be frank, NPVH casing for wells, can be used only up to a depth of 100 m and at the same time the barrel should be perfectly smooth, because the mechanical strength of the plastic is lower than that of steel. But up to 50 m, on stable ground, is ideal.

Let's talk about installation

There are several technologies for well construction for water, but the instructions below are the most common and proven.

It provides high quality and durability of the structure.

- Initially, the UPVH casing for wells begins to be mounted when switching to a smaller well diameter. This allows you to insure against movements, less stable, the upper layer of soil.

- Begin drilling with the passage of the upper, soft layers of soil with a large-diameter tool, in our case 140 mm. Deepening occurs before the onset of hard seams, as a rule, they occur at 3-5 m.

- After that, a drilling nozzle of a smaller diameter is taken that is able to withstand a greater density of primary layers. Deepening goes to the full opening of the deep aquifer.

The video in this article shows the general principle of drilling with this technology.

Important: if the water has just started to go, it means you have opened the roof of the aquifer. It should be further, until it stops in a solid layer, but it is worth not more than 50 mm to go deeper into a solid layer. Otherwise, you pierce it, and the water can go to the depths.

- Upon reaching the desired depth, the installation of the casing begins. A pipe with a cross section of 125 mm is inserted into the well and, as it dives, it is expanded using a threaded connection. During installation, rubber gaskets are used, which provide additional sealing of the barrel.

- Consider the fact that the casing pipe for PVC wells should not go as far as the stop, it only comes to the top of the aquifer, the well filter column is installed below.

- When drilling not deep wells, the whole structure can be turned on after the completion of drilling as a whole. For levels greater than 50 m, the pipes start up as they deepen.

- We draw attention to the fact that the well must be perfectly flat and perpendicular to the horizon. If the diameter is not stable or deviates from the horizon, while the column is immersed and pushed into hard layers, the product may be deformed and damaged.

- It is for this reason that firms that do not have high-quality equipment for the passage of a smooth barrel or who do not have sufficient qualifications for high-quality drilling refuse to work with this material, citing the poor quality of the UPVH pipe.

Important: The above example is not an axiom. The pipe can be of different diameters, but in this case, and nozzles for drilling rigs should be chosen in proportion to the diameter of the casing.

Conclusion

If you know for sure that the place you have chosen for the well is on stable formations, plus the depth of the aquifer is not great. Use PVC products for casing.

Work with them will be done faster and less money spent. And experts who are trying to convince you of the opposite, just trying to sell their goods.