Reinforced concrete sewer wells: features of construction

Reinforced concrete sewer wells - this design, combining such qualities as reliability, durability and affordable cost. Despite the fact that the plumbing market is annually replenished with more and more progressive and economical developments, these reinforced concrete products are still popular and in demand among both domestic and foreign customers.

What are the technologies by which the concrete sewer well is made and what are the features of its operation? Let's find out in more detail.

Construction Specifications

Modern sewer reinforced concrete wells typical, just like a few decades ago, are made in accordance with the requirements of SNiP 2.04.03-85, governing the arrangement of sewer networks.

Reinforced concrete structures are still widely used for their intended purpose in small settlements, cottage and country settlements. At the same time, wells of this type in large and medium-sized cities are gradually being replaced by polymer analogs, which are characterized by greater throughput and ease of maintenance.

Reinforced concrete wells are divided into two main types: observation and differential structures.

- Inspections are used for maintenance and control of pipelines, for connecting additional branches and for changing their direction.

- Drop structures are designed to change the height of the level of wastewater and the intensity of their movement along the branch.

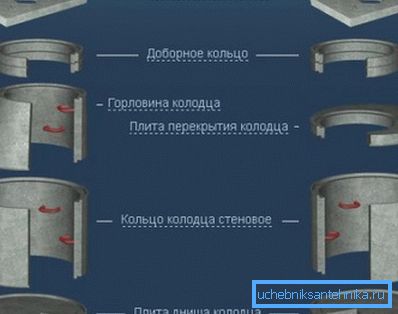

Reinforced concrete sewer manhole standard modifications is a structure consisting of the following elements:

- ring (performs the function of the side walls);

- rectangular or round base;

- rectangular or round ceiling with a round hole for the installation of the hatch;

- neck (optional);

- hatch (cast iron, and now polymer).

In accordance with previous standards, the cleaning of sewers in concrete wells was carried out only by manual method. That is, in the direction of the blockage the cable was pushed, which turned around its axis.

The dimensions of the ring were calculated on the basis of those considerations so that a person of average height could fit inside with a cable and break through a blockage or produce a complex of other equally important works. Therefore, the standard sewer well of precast concrete to this day is made taking into account the minimum size of 700 mm.

Reinforced concrete structures are also manufactured with the following standard sizes: 1000, 1250, 1500 and 2000 mm. In accordance with the shape and sizes of the main product, round plates are made - the upper overlap with a round hole and the bottom solid base.

Important: The choice of the round shape of wells is not accidental, since such a configuration is considered to be the best in terms of resistance to soil pressure.

Reinforced concrete rings standard and additional

Since reinforced concrete wells are purchased for use in various operating conditions, the plates and rings are made with a flat surface, so that they can later be joined together. Among the flat surface there are only embedded elements - mounting hinges. But, in the course of installation, the loops are cut off, and tight junction is ensured.

For the installation of the pipeline, holes are punched in the lower ring, and cement trays are arranged on the base plate to ensure that the pipeline is as tight as possible. Such constructions with the same success are used both in manholes and in drop wells. Reinforced concrete wells can be raised in height due to one or another number of standard or additional rings.

Advantages and disadvantages

Summing up the above, we note the advantages and disadvantages of reinforced concrete sewer wells.

Benefits:

- low price, in comparison with more progressive polymer modifications;

- simplicity of installation due to the presence of special lugs;

- the possibility of assembling wells of various capacities in accordance with the parameters of the object;

- the availability of these concrete goods in free sale in most domestic cities;

- applicability of concrete products on all types of soil;

- due to the inertness of the concrete, individual structural elements can be used for the construction of a key well without compromising the quality of well water;

- ease of cleaning the inner surface of the walls of buildings without the need to call a vacuum truck.

Disadvantages:

- high weight of the structure and, as a result, laboriousness of the assembly process;

- a low degree of waterproofing of a sewer well assembled from individual plates and rings;

- high probability of soil contamination by sewage, as well as an increased threat of flooding of sewage by groundwater.

Installation of sewage facilities

- We dig a hole by the size of the ring;

- Dump the bottom of the pit and drop the base plate onto it.

- Check the water level of the installation regarding the horizon.

- Cement-sand mortar lay out the perimeter of the base and do not forget to dismantle the mounting lugs.

- Further, by means of special equipment, we lower the ring directly to the pre-laid solution. Check how perpendicular to the base the ring is.

- We seal the junction of the ring and the base, using the remnants of the cement-sand mortar.

- Next, punch holes for the accession of sewer networks.

- In the upper part of the ring we cut off the mounting elements and lay out cement mortar around the perimeter.

- Further, using special equipment on the ring laid overlap.

- The joints of the ring and the overlap is sealed.

- At the final stage we install a hatch with a lid. (See also the article Features manhole manholes.)

Important: Wells, thanks to complementary rings, can be built taking into account unlimited depth. But the fewer rings used, the more tightness is characterized by the finished structure.

Conclusion

As you can see, the installation manual is not particularly difficult. These works can be done by hand using a simple tool and a crane. You can find more useful and interesting information by watching the video in this article.