Rings of wells: features, specifications, installation

Self-construction of the well is easier and more convenient to produce using reinforced concrete well rings. Of course, these rings are different, and we want to tell which products it is better to choose, how to lower the rings into the well and how to fix them in the column.

Reinforced concrete rings

Purpose

Reinforced concrete rings for the construction of wells are products of reinforced concrete of heavy grades of cylindrical shape with a vacuum inside. To put it simply, the ring resembles a short section of pipe, the length of which is approximately equal to the diameter.

The well ring is intended for the construction of a casing shaft:

- sewer,

- drainage

- viewing,

- or plumbing well,

- as well as for the construction of septic tanks,

- various collectors

- and other underground tanks.

In other words, RC rings are used for the construction of precast concrete structures, and most often these are vertical columns made up of products standing on top of one another, fastened together with brackets, mortar, or their own weight.

Most often similar products are used for the construction of the following structures:

- Wells for the extraction of drinking water. Here we need the most high-quality products both in strength and reliability, and in composition, because they will be in contact with the food product;

- Sewer wells. For the construction of these structures, products of lower quality are allowed, since the depth of such tanks is small, and there is no contact with drinking water;

- Storm and inspection drainage wells. The same as with sewer;

- Septic tanks. There are increasing requirements for the strength and reliability of the joints, as there are impurities in this tank, the penetration of which is beyond the construction limits;

- Storm sewers and drainage system. These structures are subject to high demands for water resistance and durability.

Note! So, we can say that reinforced concrete rings are used for the construction of various hydraulic structures and to strengthen the vertical shafts of well shafts.

Specifications

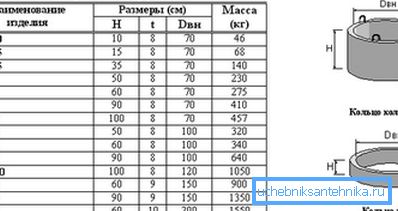

Concrete products for the construction of well trunks have a wide range of characteristics. The main ones include the height of the product, its internal diameter, as well as the mass, volume and thickness of the walls.

The first two characteristics are indicated on the ring marking. It consists of the letters KS and two numbers. "COP" stands for "wall ring", and the numbers indicate the inner diameter (first in order) and the height of the part (second number). For example, a product with marking KC 10-9 has an internal diameter of 10 decimeters and a height of 9 decimeters.

The size of the concrete goods can be very different: the height varies from 1 to 12 dm, the internal diameter - from 7 to 25 dm. For the construction of water accumulation wells, the products most often used are marked with COP 10–9, since they have an optimum width, and 90 cm of height result in a mass of from 550 to 630 kg, which is also quite acceptable.

The wall thickness can vary from 8 to 10 cm, in addition, the ends of the ring can be flat or have a lock in the form of a flange. Locks allow you to make more durable structures and avoid horizontal displacement of the column during the heaving of the soil.

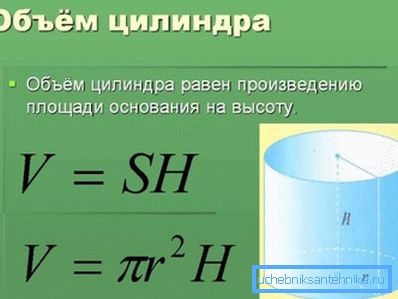

The volume of the product can be easily determined by the formula:

V = S * h, where V is the volume, S is the area of the base of the cylinder, h is the height of the cylinder.

The height is indicated in the marking, but how to determine the area of the base? Elementary:

S =? R2, where? = 3.14, R =? D, D is the diameter indicated in the marking.

As a result, we obtain: V = 0.785 * D2 * h, moreover, D is the first number in the marking, h is the second number in the marking of the part.

For example, let's calculate how many liters are in the KS 10-9 well ring:

V = 0.785 * 1 * 0.9 = 0.7065 cu. m = 700 l.

In some products, the height may be equal to 89 cm, respectively, the volume will be slightly lower.

The same calculation can be used to calculate the volume of water in the water receiving part of the barrel, but instead of the ring height, substitute the height of the water column, which can be easily determined by dropping a rope with a load into the well and measuring the length of the wet part.

Assembly of structures

Now we want to tell you how to work with concrete rings during the construction of the well. As already mentioned, they use for this purpose a variety with the marking COP 10-9.

The presence of a lock is not necessary, many installers tend to flat ends, because the quality of locks is often not up to par, and because of this the products become uneven, in addition, the price of the part with folds is about 500 rubles higher. Finally, skeptics argue that the force of the heaving of the soil will not be able to hold any lock or other fastening, as it can reach several tons per square meter of the surface of the structure.

If you plan to build a well with your own hands, you will find the assembly instructions for reinforced concrete useful:

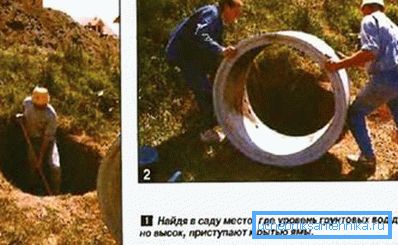

- A pit is dug in the ground for the first ring about one and a half meters deep. The diameter of the pit - 1.3 - 1.5 m;

- A tripod with a lifting hoist or a winch is placed above the pit, at the end of the cable of which there are stubs with four hooks;

- Before lowering the rings into the well, the bottom of the pit is leveled and tamped;

- Concrete goods put on a lateral surface by means of scrap or other lever and rolled to an installation site like a wheel;

- The mouth of the pit is covered with a wooden shield of durable boards, on which the product is rolled up and put on the end;

- Chamfer hook mounting brackets, imbedded in the ends of the ring, and begin to lift the concrete products over the pit;

- When the ring hangs on the cable, the shield is removed from the mouth of the pit and the product is lowered, while at the same time adjusting its trajectory by pressing on the side surface and rocking it;

- When the ring is in the design position, the mounting ears are folded inward, and the end is coated with a solution of sand, water and cement. In general, there is a lot of debate about how to miss the ring of the well, we offer the most simple and environmentally friendly option;

- After that, the pit is again covered with a shield, the next product is rolled onto it, lifted on the rods, the shield is removed and placed on the previous part. The accuracy of the installation is adjusted manually or using levers;

- Then dig up the soil from under the column, and when it falls below the surface of the earth, the process is repeated again;

- After assembling the entire column, the joints are coated with cement mortar mixed with liquid glass.

Note! Acquire concrete products only from reliable manufacturers with a good long-term reputation, since the life of the well and the condition of the water in it will depend on their quality.

Conclusion

Reinforced concrete rings - the most convenient and safe material for self-construction of the well. For their installation is enough two or three people and a simple lifting mechanism, the video in this article will help you better understand the intricacies of work.