Rope ladder for a well - manufacturing nuances

Every well from time to time needs maintenance and minor repairs. To do this, of course, you have to descend into the mine, therefore, having a well, you must take care of comfortable and safe descent into it. Therefore, below we will consider how to make a suitable ladder with your own hands.

General information

I must say that you may need to go down the well much more often than you think. For example, if a foreign object gets into the water, breaks the chain, etc. (read also the article Fire hydrant in the well - installation rules).

There are several of the most common descent designs:

- Staples mounted in the wall.

- Wooden added design.

- Rope ladder for wells, which easily descends when necessary and also folds easily.

Now consider the features of each option.

Staple construction

This option can not be called the best solution, as metal brackets begin to rust over time, and in some cases even break the tightness of the shaft. Therefore, it is more expedient to use brackets when performing the ladder for sewage wells, but not water.

Tip! When using metal staples, to increase the service life they must be coated with anti-corrosion paint.

Wooden

The wooden structure is more convenient to use, however, it also has many flaws and the most important of them is that it is almost impossible to use it for deep mines, since the structure will be too long. In addition, due to its large size, it is difficult to ensure its storage and transportation.

Therefore, this option is not suitable for all cases. But the ladder for a sewer well made of wood can be operated quite successfully.

Rope

Well ladders, made of ropes, have quite a few advantages, among which are the following points:

- Compactness, making them easy to store. In this case, this is a very important point, since the product can be stored in the house and lowered into the source shaft only if necessary.

- Mobility - the product weighs a little, making it easy to transport.

- The low price of materials, due to which the cost of such a product is much lower than that of metal or wood structures.

- Possibility of adjustment, thanks to which the product will be the length that you need.

- An opportunity to use not only for a water source, but also for other purposes.

- The product can solve the problem of descent and ascent in cases where it is impossible to use other types of structures.

Making rope ladder

It must be said that the ladder for wells does not differ by any special requirements. The only thing is that it should have sufficient strength. Since, most likely, you will have to lower or lift something into the well, the steps must withstand at least 110-120 kg.

Materials

For the manufacture of ropes, which will serve as the basis of the design, you can use the following materials:

- Polyester;

- Nylon;

- Cotton fibers;

- Fibrous plants such as hemp, flax.

All of these materials, if used in sufficient quantities, will be able to bear the weight of even a few adults. In addition, they are easy to fold and fold, so that the ladder easily descends into the well, after which it is also easy to fold and transport.

However, it should be said that synthetic materials are the best option for the stairs to the well, since they differ:

- Moisture resistance;

- Durability;

- Solvent resistant.

For steps, as a rule, use:

- Tree;

- Rope (you can use the same material as for the base);

- Metal (most often light alloys);

- Plastic.

In our case, we will need the following materials:

- Two coils of polypropylene rope, each 20 meters long. The diameter of the rope - 8 mm. This material is good because it is not afraid of water and does not stretch.

- 7 polished cuttings 3 cm in diameter and 140 cm long

- A roll of thick coarse thread.

Manufacturing

After the materials are prepared, you can proceed to the manufacture of stairs to the wells. This process consists of only a few steps.

So, the instruction looks like this:

- The first step is to cut the cuttings 30 cm long each. There should be a total of 25 segments.

- For reliability, you need to make grooves in the steps, departing from the edge of one centimeter.

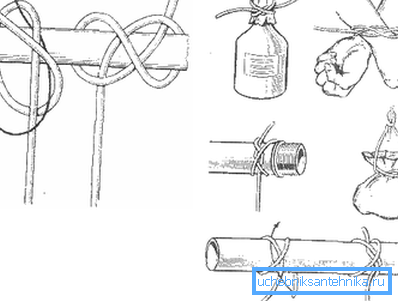

- To mount the structure, it will be necessary to study the technique of tying the constrictor unit, which will allow to avoid making holes in the cuttings. The loops for the steps should be made evenly along the rope, at a distance of 45 cm and with a diameter of 6 mm.

- Further, loops on another rope are also performed and steps are inserted into them. The result is an 11-meter design. In this case, in the uppermost loops, the steps can not be inserted, as they will be needed to fix the structure.

Tip! So that the rope does not open, its ends must be singed. To do this, you can use a hot knife.

Now the well ladder is ready, you should once again make sure that the steps do not slide and after that you can start its operation.

Conclusion

A ladder is a necessary element for any well, since without it it is impossible to maintain the source. For deep mines, the best option is a rope structure that can be performed independently. However, this must be done carefully, since your safety will depend on it (see also the article “Stormwater wells: construction objectives, types, materials used).

Additional information on this topic can be obtained from the video in this article.