Selection of the pump for the well, depending on the

To purchase a device for pumping fluid, you need to decide on the place of its installation and the principle of operation, as well as take into account some other factors. Having considered the main types of devices, you can easily understand how to choose a pump for a well on the site. However, along with this, it is necessary to take into account the power of the unit, which depends on various circumstances.

Surface apparatus

Such devices can be above the level of the pumped water only up to ten meters, since with a greater distance to form the desired vacuum in the system is quite problematic. Their design provides a suction hose, immersed at one end in a source of fluid.

Listing Basic Benefits

- In the absence of the need to immerse the unit in water, repair and maintenance work is greatly facilitated.

- Self-priming pumps for wells can be placed not only near the neck, but also at some distance.

- Modest dimensions and light weight allow you to move almost any model on the site.

- A wide enough range of temperatures for operation, which ranges from 0 to 35-60 degrees Celsius. The upper limit depends on the specific model.

- When using, enhanced safety is provided, because these devices are protected from the effects of electric current and penetration of splashes inside.

Main varieties

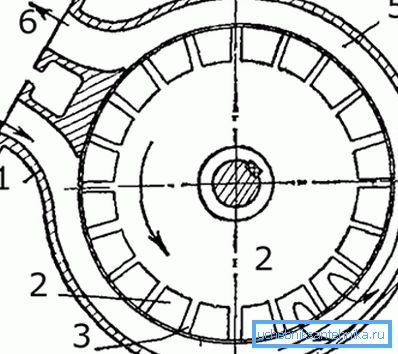

Surface products are divided into two types, based on the depth of absorption.

At a normal water level, you can make a choice in favor of any analogue, but in the case of an increased distance, it is better to use a centrifugal pump, since it will allow a larger water intake.

- Vortex products provide the ability to pump liquid from a shallow depth, so most often it is used to control the pressure in the water supply system.. However, in some situations it is still used to extract water from the well. The main advantage is the price of the device.

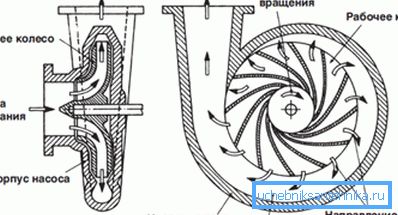

- Centrifugal analogues form the necessary pressure due to the centrifugal force, which is formed when the blades directly on the liquid. Therefore, they allow to take water from an increased distance, but it is usually limited to ten meters. Recently, models have appeared not with one impeller, but with several at once, which increases the vacuum.

Note! With a small depth of drinking water, the best pump for the well is centrifugal, as it provides an excellent opportunity to supply liquid at a low cost of the device.

Installation process

To install and connect surface-type devices, you can not hire performers, because all the work is quite realistic to do with your own hands, having familiarized yourself with the basic rules of operation. An independent connection to an autonomous source will save finances.

The following are basic points that need to be well understood.

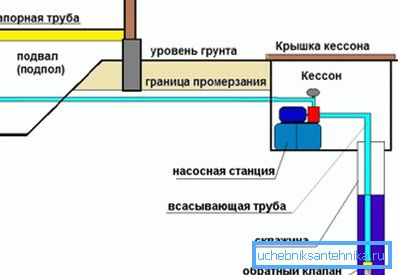

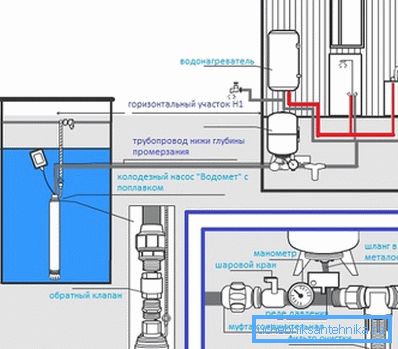

- It is necessary to install such systems into a closed structure at the well or an internal caisson. At the same time care should be taken of high-quality insulation.

- It is advisable to install the equipment on a previously prepared base equipped with fastening pins. Due to this, vibration loads will be reduced, and the operational life of the device will also increase.

- It is mandatory to install an automatic control system that facilitates the use of the product. The inlet is connected to the supply pipeline, which fits inside.

- If necessary, a hydraulic accumulator is added along with an expansion tank. Immediately before its launch, the pressure in the chamber is checked. It must meet the requirements of operation.

Attention! At installation of the hydroaccumulator the powerful pump for a well pumps over liquid through pipes in a special membrane. The process occurs until the pressure reaches the desired level.

Depth aggregates

Such products are completely immersed in water, making it possible to rise from a greater depth. In this case, a high-quality cooling of the device nodes It is mainly used only for the extraction of drinking water at a distance of more than 10 meters.

List of key benefits

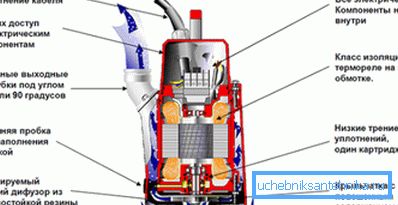

- Such mechanisms can create a high pressure without increasing the consumption of electricity, which affects the economy.

- Adjustable rotation frequency allows you to pump water in economy mode, thereby ensuring long-term operation.

- Resistance to overloads and wear is ensured by a smooth start, protecting electrical pumps for wells of this type from water hammer.

- Thanks to the integrated sensor, it is possible to control the overheating process by disconnecting the system from the network.

- Silent operation of such a system allows you to enjoy the silence.

Types of similar devices

As a rule, such products are divided into two types, the main characteristic of which is the location of the engine.

The actuating device can be located both at depth and on the surface of the water.

- Rod devices have a mechanical connection with the engine located at the top. Thus, it turns out a floating pump for the well, providing water production in shallow wells.

- Rodless mechanisms are performed in the same housing with the engine. Power is usually supplied by a submersible power cable. Models of this type are widespread.

Addition! As for the principle of operation, they distinguish screw pumps for wells and centrifugal analogues. The efficiency of the latter is much higher, but this is largely reflected in the cost.

Installation basics

Before installation, you need to take into account the intensity of pumping, as well as the amount of water for the proper functioning of the device. If high quality is required first, then it is better to purchase Italian pumps for wells.

In this case, the installation requirements are somewhat reduced, but some points should be taken into account during installation.

- It is impossible to carry out installation directly to the bottom, because after a while dirt accumulates there. At hit of large particles the wear rate considerably increases.

- The body of the apparatus must cover a layer of water of at least 2 meters. If this distance is somewhat less, then during pumping it is necessary to carry out a periodic inspection so that the device is not outside.

- In the case of a stationary installation, plastic or metal pipes capable of withstanding a certain pressure are installed for sharing with a hydroaccumulator.

- Fastening is done by hanging on a cable that can support the weight of the entire unit. It is best to buy a cord of nylon or metal with a corrosion-resistant coating.

- In order to prevent the system from touching the side walls during operation, a special rubber ring is tensioned onto the case. This in emergency situations will provide mitigation upon impact.

Advise the pump for a well of submersible type! Answer: The most reliable are models in which the case is made of stainless steel, so it is recommended to purchase them.

Additional Information

- It is necessary to understand that the efficiency of the deep device is much higher than that of the surface analogue, because the last of them has a certain amount of power spent on the formation of sparsity.

- The design provides that ordinary water is used as a coolant, therefore overheating in some situations is still possible. Therefore, in the acquisition process, you need to pay attention to the presence of a control sensor.

- The housing must be perfectly sealed. As for the flow part, it also has special requirements. The main of them can be attributed strength and durability.

- It is necessary to take into account the characteristics of the engine. Although many household structures are connected to a normal network, there are some models that need a three-phase connection.

- The presence of thermal protection is also an important point. In case of sudden power surges without this function, the device will quickly fail.

- When choosing, one should make a start from the depth of the well, the dynamic and static water level, the degree of its contamination, the temperature regime and some other factors.

- It is not recommended to install vibration aggregates in well billows, otherwise the need for maintenance will increase to a great extent.

- With an insignificant water level, it is advisable to choose products with a lower water intake or purchase products that are approved by the manufacturer for horizontal placement.

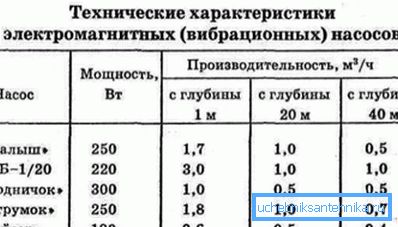

- Even before the purchase, you need to decide on the mode and objectives of water supply in order to select the device of the desired performance. Power is calculated by the formula: H = Hp + (0,2xL) +15, where H is the required head in meters, Hp is the height difference, L is the length of the water supply system, and the last digit is the recommended correction.

As a conclusion

This manual is intended to introduce the main types of devices for pumping water suitable for certain conditions. Detailed information contains a video in this article. If it is not possible to spend money on electricity or other types of fuel, then you can install a mechanical pump for the well and raise the liquid manually.