Self-cleaning hole

The need to carry out repair work in a well is often associated with a decrease in its flow rate, water quality, the appearance of sanding processes, which lead to silting of the well and the failure of water-lifting equipment. There are several ways to resume well production: hydraulic, mechanical, chemical, which requires special equipment that is not always available.

A slug is a section of a metal pipe, in the lower part of which a valve is installed. When lowering the pellet to the bottom of the well, sand or clay gets into the middle of the pipe and is held there by a valve; lowering and lifting operations are carried out several times until the shell is filled with dirt and sediment. Then it is lifted to the surface, the rock is removed from it, and the operation is repeated.

The most common are two types of scone: a flat valve and a valve in the form of a ball. A ball valve with a ball valve is considered to be more reliable and efficient, due to the lack of a hinge, and a flat valve valve is easier to manufacture.

With ball valve

To make a ball valve, you will need:

- a section of a thick-walled metal pipe with a diameter of 89 mm and a length of up to 1.5 m;

- 89–57 mm concentric steel transition;

- metal ball with a diameter of 6 cm.

The ball is selected according to the internal diameter of the well being cleaned, and should be 2 cm smaller than the diameter of its narrowest part. In order for the ball to fit snugly to the concentric transition, it is necessary to process its edge in the narrow part with emery paper. Further, a concentric junction, with a side with a smaller diameter, is inserted into the pipe and welded around the contour. A ball is lowered inside the pipe, and at a height of 5 cm it is necessary to install a limiter so that the ball does not bounce high and low when it lowers the hole into the well when it is empty. In the role of the limiter may be a metal rod inserted into a drilled hole in the pipe, and welded. The lower part of the shellfish, which will hit the bottom, needs to be sharpened, only the inner side is ground, for 3–4 metal tusks are welded from the bottom for greater efficiency of loosening. In the upper part of the pipe you need to weld a metal loop for fastening the cable, you need to weld from the inside.

If it is problematic to find a metal ball, it can be replaced with a rubber or plastic ball of suitable diameter, filling it with a mixture of lead shot and epoxy glue.

With flat valve

The design of such a yolk is considered more simple. The base of the shells, as in the previous version, is taken as a pipe section with a diameter corresponding to the diameter of the well. In the lower part of the pipe, a shoe is welded, which has a diameter of 3– b mm larger than the diameter of the yolk. The washer is welded inside the pipe. For the manufacture of a flat valve is used a metal plate, the size of which is larger than the diameter of the washer. The plate is attached with a swivel, as long as it provides free opening and closing of the valve.

It is necessary to weld a limiter in the form of a metal rod to the inside of the valve, to limit the opening of the valve at a level of 70–80? - it will not let him jam.

Well cleaning process

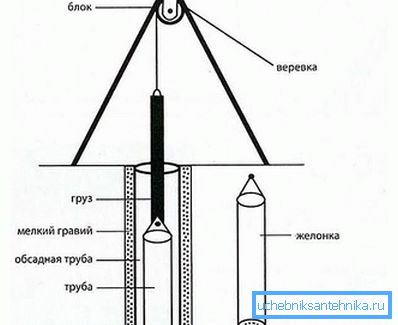

After you have made the pan, you still need to apply it correctly. Cleaning the well with a sludge process is very laborious, but reliable. To facilitate the baking process, a tripod is installed above the well, and a block is attached to it from above. To the shell through the carabiner you need to tie a cable or a strong rope. The length of the rope must exceed the depth of the well. If the shell is too heavy, you can use a winch or brace to facilitate lifting.

Particular attention should be paid to the mount, since in case of a breakage of the yolk, it will be very difficult to remove it back.

Through the block, it is necessary to throw the cable and lower the shell on the bottom of the well, but not with a sweep, but holding the cable a little, otherwise the shell may jam. When lowering the broomstick, be careful and work with canvas gloves to avoid hurting your hands on the cable.

As soon as the shell sinks to the bottom, it should be raised to a height of 30–50 cm and sharply lowered. When struck, the valve opens, and the turbulent water with sand gets inside the jelly. The operation of raising and lowering must be repeated until the shell is filled, you feel it by weight. Then the slug is removed, the contents are poured and the remaining dirt and sand is tapped.

Video

Watch two videos about rock drill. They provide an overview of homemade glass and zhelonka:

Photo