Sewer well - types and features of operation

What is a sewer well, for what purposes is it used and what should be considered when choosing it? These questions are relevant to this day, because without a full-fledged system of disposal of wastewater and waste about the comfort of living in a country house can not be considered.

In order to external sewage in the country or in the cottage differed efficiency and reliability, it must not only be properly installed, but also correctly selected. In this article we will look at what a sewer well, built on the basis of concrete rings.

The choice of such a construction is not accidental, since, despite the fact that polymer and plastic analogues appear on the market, it is the reinforced concrete structure that is installed everywhere in the country.

Classification according to purpose

The sewer well is used to organize turns, pipe swings and other elements of the sewer system.

In accordance with the purpose, the wells are divided into the following types:

- viewing;

- washing;

- accumulative (cesspools);

- differential pressure;

- control;

- rain;

- special purpose.

Let us consider in more detail each of the listed types.

- Inspection wells installed in the longest part of the pipeline, as well as when the level drops due to the features of the soil relief and when turning the system.

Through this facility, you can inspect the pipeline for blockage and, if necessary, clean it.

- Wash well it is mounted at the highest point of the network and is used for routine flushing of the pipeline.

- The volume of the sewer well cesspool type used to collect waste. Installation instructions for this facility are as follows:

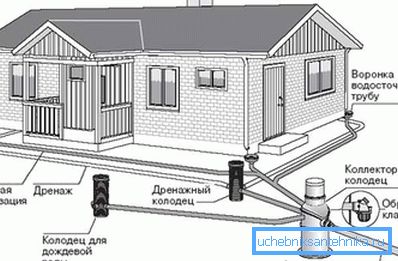

- The accumulator of drains should be located in the territory adjacent to the house.

- The construction should be further 10 meters from the water supply and further 20 meters from the water intake shaft or well.

- The distance from the sump to the house or other residential structures should be 10 meters. This requirement is designed to eliminate the likelihood of flooding and destruction of the foundation of the house and outbuildings in emergency situations.

- The distance from the structure to the fence on the site should be from 1 meter or more.

- The calculation of the volume of the sewer well is determined depending on the average rate of waste and the depth of groundwater.

- Drop well it is applied on sections of the pipeline with sharp decrease in level. The main purpose of the facility is to ensure the discharge rate of the flow of wastewater.

The height of the well differential type is not more than 4 meters. This limitation is explained by the need for the sparing effect of falling water, since falling water from a greater height for many years can lead to the destruction of the entire structure.

- Control well as intended similar to the viewing counterpart. The only difference is that it is installed at the site of the union of two or more networks. Also, such designs are relevant in the transition from one thickness of pipe to another.

- Rain wells designed to collect wastewater from drainage systems.

- Special sewer well it is necessary in case the sewer system intersects with the main pipelines.

Important: Before descending into the water well sewer, it is necessary to make sure that the air is polluted and that the content of potentially dangerous gases is absent. In order to make the measurements as accurate as possible, a gas analyzer is used for sewer manholes.

Construction features

The sewer system well consists of three main structural elements:

- bottoms;

- manhole part;

- connecting part.

Important: If the diameter of the pipeline is 30 cm, meter rings are used for the well, at the same time, the manhole should not be less than 70 cm. When using pipes of larger diameter, the standard bottom with a diameter of 1 meter will not work. For the correct installation in the bottom we punch a hole of the required diameter.

Not long ago, wells were built exclusively with the use of bricks and concrete. The process was laborious, which negatively affected the cost of the system as a whole. In addition, the structures constructed in this way were not the most durable and required periodic repairs.

In place of inefficient technologies came industrialized reinforced concrete structures. The cost of sewage systems built with the use of reinforced concrete, has become much more accessible, and the operational resource has grown significantly. And most importantly, the timing of the construction of sewage reduced by several times!

From reinforced concrete structural elements it is possible to assemble sewer systems of various configurations and various degrees of complexity. This is largely due to the fact that concrete products have clear standard values, and the range of such products includes dozens of different modifications from which to choose one or another option.

Tip: Laying the sewer pipe, do not make sharp turns. For example, the angle between the inlet and outlet pipe should not be less than 90? . Also, in order to eliminate the possibility of pipeline deformation, the turning radius must be greater than the diameter of the pipe.

The elements of sewer wells include the following concrete products:

- additional rings;

- plate road with the top location;

- floor slab used in sewer systems with large diameter pipes;

- neck;

- wall ring;

- bottom in the form of solid concrete slab.

By the way, similar components are used for the construction of reinforced concrete wells for heat and water supply.

Using the listed reinforced concrete parts, you can create sewer typical wells for various communications used in the transport of household and industrial liquids. An important advantage of reinforced concrete wells is the simplicity and effectiveness of waterproofing devices.

Important: Despite the fact that reinforced concrete sewer wells can be used everywhere without any significant restrictions, in permafrost conditions these structures are irrelevant. Therefore, in the northern regions should resort to the use of other technologies.

In accordance with the operational requirements, two types of reinforced concrete elements are produced:

- Modifications of concrete of medium permeability, adapted for use on ordinary soils in the construction of closed pipelines and manholes.

- Modifications of low permeability concrete, adapted for use on any type of soil in the construction of closed pipelines, collectors, manholes, septic tanks, etc.

Main advantages

- Industrial production of reinforced concrete rings by the method of vibropressing is an affordable price and durability of all components of the structure.

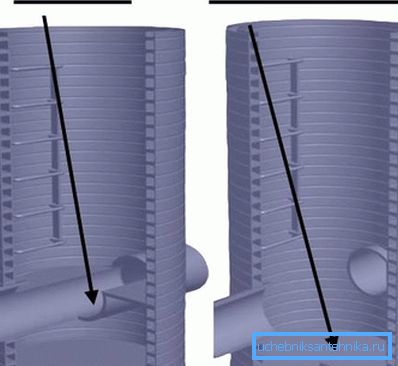

- Thanks to the special protrusions on the rings, an optimum assembly integrity is ensured. As a result, the wells demonstrate resistance to ground movement, which has a positive effect on the degree of water resistance of the prefabricated structure.

- Due to the presence of mounting holes and protrusions, it is easy to assemble and install the well with your own hands.

- In most cases it is possible to order reinforced concrete rings with initially prepared holes in which pipes with a diameter of 20 to 60 cm can be installed.

- Simplicity of maintenance service is a quality that distinguishes the use of a well from reinforced concrete rings. The fact is that on the inner walls of the product there are special metal brackets that you can go down into the cavity of the well.

- All industrially manufactured elements of sewer systems are manufactured in compliance with the requirements of GOST. To ensure maximum strength of the rings, special concrete with fine-grained backfill is used in production, which, in combination with reinforcing rods, provides the best strength properties.

Conclusion

As you could see, choose and use the sewer well for its intended purpose is not difficult at all. The main thing is to correctly calculate the volume of the facility in accordance with the performance of the sewer system used.

More useful and interesting information you can find by watching the video in this article.