Shower watering: store models and own production

Recently, many different systems have begun to appear, which significantly increase the level of comfort when taking water treatments. At the same time, most developments are used in the field of water supply, especially if they additionally help to save. That is why the shower with a valve has become very popular.

Factory products

Currently, this area of the market has become one of the most common and extensive. In modern stores you can see just a huge number of various models of these products, with different designs and operating principles. Therefore, questions about how to disassemble a shower watering can be quite relevant and are quite common.

The principle of operation and purpose

- First of all, it should be noted that the operation of such devices is based on the principle of spraying a jet of water, stopping it in many small droplets. At the same time there are such products that have a mode with the effect of fog almost turning the pressure into water dust.

- Typically, this effect is achieved by installing a plate at the exit of the design, which has many small holes.. However, there are some models where valve or peculiar ball mechanisms are used. Although typical ceiling shower heads that do not work with great pressure, use typical nets.

- The simplest purpose of such a product is to increase the flow area, which allows more efficient use of fluid volume.. At the same time, water consumption is significantly reduced, which leads to big savings, especially noticeable in those regions where the price for it is quite high.

- It should also be noted that there is a medical practice, which involves the impact on the human body with directed jets. Therefore, certain designs have a massage mode.

Tip! Experts recommend purchasing systems with multiple functions. They cost a little more than ordinary shower heads, but much more practical and comfortable.

Species

- For a start, these systems are divided by place of installation.. The fact is that stationary shower heads, in the form of ceiling structures, can usually operate with a slight water pressure and have large holes. While mobile products or fixed on a rigid gander work with pressure, which allows them to operate in different modes.

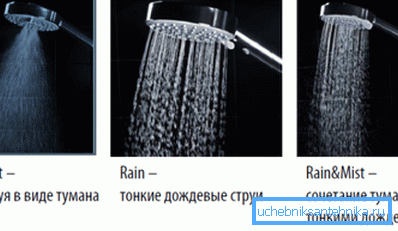

- Virtually all such products can be divided by the type of jet that they give out.. The fact is that many manufacturers themselves develop original types of water supply, which differ in the number of jets, their thickness, combination and even different pressures. However, they are selected individually, guided by personal preferences.

- Separate attention deserve shower heads for the bathroom equipped with special valves. They block the flow of liquid right near the sprayer. It is very convenient to use both in the ceiling system and on the product with a flexible hose.

Tip! By purchasing such a device separately from the tank or mixer, you should immediately make sure that the inlet is suitable for the pipe or hose mounted on the product. Otherwise, you must buy the appropriate adapter.

Independent production

Immediately it should be said that sometimes it is easier to purchase a finished structure than to do it yourself. However, there are situations in which the store is very far away, and the desire to take a shower makes one show imagination and ingenuity.

Simplest products

The easiest way to use for such purposes is a regular plastic bottle. It will make a good watering can for a shower cabin, since the neck can be put on the hose or pipe very easily, and multiple holes in the bottom make it possible to create a wide variety of spray nozzles. It should be noted that this design can work even under slight pressure.

You can also create a similar product from an ordinary garden watering can. It's enough to become her nose and fix it on the pipe or hose. Some masters make it themselves out of tin.

Separate attention deserves another simplest method, which often describes the instructions for independently making various devices. It lies in the fact that a crane is hung on the crane, in the bottom of which holes are made. However, this design is rather cumbersome and inconvenient.

Tip! All the simplest systems are usually designed to work with water that goes by gravity or with a small pressure. For pressure constructions it is better to use factory products.

Repairs

Usually repair shower head is that it is necessary to eliminate the leak that may arise during the operation. Therefore, for plastic structures use glue or rem kit for plastics, and metal systems are best soldered.

If the product has become clogged, it must be cleaned. At the same time remove the nozzle and blow it with air. You can also clean the holes with metal wire.

When repairing systems with a valve, it is disassembled first. This may require replacing the gaskets or inserts.

Tip! The cost of such products is relatively small and it is sometimes easier to replace them entirely. It will save a lot of time and nerves.

Conclusion

After reading the video in this article, you can get more detailed information about such devices and their varieties. At the same time, taking into account the article outlined above, it is worthwhile to conclude that it is possible to assemble the simplest product of such a principle of action in a few minutes. You do not need to have special skills and education.

However, even the simplest white plastic shower head can be much more efficient. Therefore, it is considered that it is better to purchase the finished product.