Silting and cleaning methods

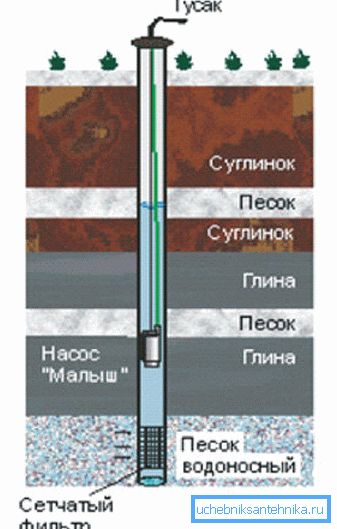

The well for the extraction of water is called vertical generation, which is created using a special drilling rig. For private households, wells are used that draw water from a sandy aquifer. A filter is mounted in the lower part of the installation, which should prevent sand and other large particles from entering the target.

During operation, the system is sometimes silted up, which can lead to the cessation of water flow to the surface and even breakdown of the pump. We will understand why the well is silted up and how it is possible to deal with this misfortune.

Silting process

Silting is the accumulation of fine sand, rock particles and sludge in the lower part of the trunk. Passing into the target through the filter, these particles gradually fill the bottom of the sump. In connection with this process, the flow rate decreases, and the system may stop working altogether..

The silting process takes place gradually, it can be noticed by the following features:

- increase in water concentration of sand impurities;

- lowering the water pressure from the water supply device;

- turbidity of water.

The reasons

The reasons for silting can be various processes caused by certain facts. These reasons may be associated with improper operation of the system, and may be hidden during the installation phase.

Consider the reasons for which silting can occur.

These include:

- incorrect installation of the casing, which leads to a low production rate of the system initially and its rapid clogging;

- use of poor-quality filters in the well system, incorrect calculation of the perforation of the column, sprinkling is not performed;

- the appearance of cracks in the casing, depressurization of pipe joints, sand and suspensions in this case can come from the water pipe;

- simple system for a long time;

- silting at the estimated operational time through the filter mesh with fine particles.

In any case, if silting occurred, it is necessary to clean the well.

Council As soon as you notice that sediment and sand appear in the water from the system, and the inflow of water has decreased, it is urgent to start cleaning. Otherwise, you can be completely without water.

Well cleaning

The natural question is what to do - if the well is seeded, or if the water goes turbid, if the water stops flowing completely, it is solved only by cleaning.

There are various options for solving this problem, the main ones are:

- flushing the well with a large water pressure;

- blowing under the pressure of the air;

- pumping for a long time by pumps.

Hydrodynamic washing

This cleaning method is quite laborious and is made only by specialized firms using specialized equipment.

The work includes the following actions:

- dismantling of the pump operating in the installation;

- hydrodynamic high-pressure cleaning of the filter, casing and sump;

- installation of a temporary pump;

- pumping dirty water;

- dismantling the temporary pump;

- installation of the main pump.

Purge

With this method, air is pumped into the system under high pressure, which pushes water from the barrel along with debris to the surface. Cork from silt and sand is destroyed and also pushed out with water.

Blowing with the help of a compressor copes well with silt and sandy sediments, but it is powerless against lime or iron deposits. In this case, you will have to resort to cleaning with reagents.

Pumping

When washing and purging there is a danger of damaging the filter, as work takes place under high pressure. Pumping involves a more careful attitude to the equipment, and the process itself is much easier to organize.

Pumping is called such a method, when the target is cleaned by pumping water from it in large quantities. Sand, sludge, and other contaminants are also pumped out with water. The pumping can be done with the help of a hopper or conventional pumps.

We will talk about one of the methods that will allow you to cope with the problem yourself within a few hours. You only need to stock up on a large water tank, for example a barrel of 200 liters.

Step-by-step instructions for pumping the valve using two pumps:

- we install on a surface capacity of 200 liters;

- in the tank we fix the bucket, in which instead of the bottom there is a fine mesh;

- we lower in the bucket the hose of the self-priming pump;

- the end of the other hose is lowered to the bottom of the well, tying a weight to it;

- install a submersible pump in the range approximately at a height of 20 centimeters from the sludge layer;

- turn on the submersible pump and wait until the tank is filled;

- turn on self-priming device, it supplies water from the tank to the bottom and loosens the layer of sand and silt;

- the submersible pump will pump out the dirty water until the layer of silt with sand is completely destroyed and the water is clear.

Council For pumping with this method it is best to take a special submersible pump that is designed to work with polluted water. If the price of such a pump confuses you, but there is an ordinary submersible pump on the farm, you can use it. But in this case, it is necessary to periodically pull it out of the well and pump pre-harvested clean water through it. Otherwise, it can become clogged and deteriorate.

Summary

Sooner or later, but any well must be cleaned. This is necessary so that the system will give clean water in an uninterrupted mode, and sand and other minor impurities do not interfere with the operation of the equipment. In the presented video in this article you will find additional information on this topic.