Stainless steel ball valve - types and features

The stainless steel ball valve is used in pipelines as a shut-off valve, which completely blocks the flow of the working medium. In this article we will consider the features of this device and its scope.

General information

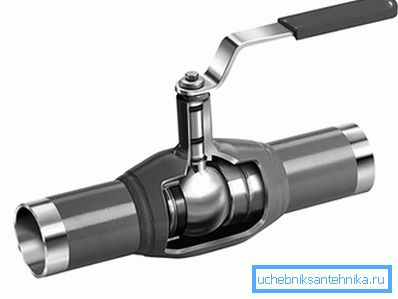

So, the ball valve is a kind of pipe fittings, the locking element of which is made in the shape of a sphere, hence its name. It must be said that such a construction has been known to mankind for more than a hundred years.

At first, this device was not in great demand, but with the advent of various modern materials, including stainless steel, it became widespread. The main advantage of this valves is simplicity of design and, as a result, reliability and durability.

Device and features

Like any other valves, stainless steel ball valve consists of two main elements:

| Enclosures | It can be very different forms, depending on the purpose of the device. |

| Rolling element | It is a ball fixed in the saddles. The ball has a through hole that serves as a passage for the flow of liquid or gas. |

In household valves, as a rule, the diameter of the bore hole is equal to the internal diameter of the pipe. Therefore, it is called full bore.

Most often this type of valves is used in the following types of pipelines:

- Water pipes;

- Gas pipelines;

- Heat pipelines.

Special features

First of all it should be said that the stainless steel ball valve is not designed to work as a throttling or regulating valve. It should be used strictly for its intended purpose, i.e. for full overlap or opening flow.

Rebar opening is performed by turning the handle counterclockwise 90 degrees, i.e. until it stops. For ease of use, the design has a limiter stroke lever.

Merits

Among the advantages of the valves considered are the following points:

- Small size;

- Simplicity of design;

- Convenient control of their own hands;

- No stagnant zones;

- Simple installation instructions;

- High tightness;

- Reliability and durability;

- Low price, due to the simplicity of the design.

For these reasons, this valve is found in almost every apartment and every home.

disadvantages

Along with the positive aspects, this product has some drawbacks, which are listed below:

- There is no possibility of adjusting the flow. If you use the device for these purposes, it quickly depressurized.

- The ability to use only for systems with low pressure - for gas pipelines not more than 10 bar and for water pipes not more than 16 bar.

- The limited size range - the larger the diameter of the pipes, the harder it is to find a suitable device for them.

Tip! Plastic ball valves can be used in conjunction with a plastic pipeline; their cost is lower than that of stainless steel, while durability and reliability are high.

Kinds

The classification of the valve under consideration is carried out according to several criteria:

| The shape of the passage | There are several types:

|

| According to the material of the seal | The compactor can be:

|

| According to the shape of the body | Connectors can be positioned relative to each other:

In addition, the devices are straight and three-way. |

| By way of installation and type of housing design | There are:

|

A particularly important point is the method of installation and the type of design of the case, since the area of application depends on this, therefore, below we take a closer look at the features of these devices.

Coupling

Stainless ball valve has a female thread on both sides. As a rule, such fittings are applied to water pipes.

According to the control method, these devices are of three types:

- Lever;

- Electrically driven;

- Gearbox.

If the nominal diameter does not exceed DN125, then the device is controlled by a lever. If the diameter is larger, the optimal solution is a gear control. The electric drive is used where two-position regulation is used, or shut-off valves are difficult to access.

Flanged

Stainless steel ball valve flange found its application in the oil and gas industry. They are used in pipelines transporting gas, oil, and other chemicals.

As it is easy to guess from the name, the stainless flange valve is mounted with the help of flanges that are on both sides.

The main advantages of this device are:

- Low cost;

- Long service life;

- The possibility of use for suspensions, viscous and contaminated media, sludge, etc.

Of course, a stainless flanged ball valve can only be used if the pipes are also equipped with appropriate flanges.

Ferrule

From muftovyh differ primarily in the fact that they have an external thread. Most often used in the petrochemical industry. The device is connected to the pipes with cap nuts.

Welded

From all of the above products, this valve is distinguished by the fact that they are mounted by welding. Most often it is used in centralized heat supply systems. The main advantage of this design is the complete tightness of the connection. (See also the article Hermetic for pipes: features.)

Tip! Devices with a small diameter can be used for domestic purposes as a drain. For example, you can use this tap for a stainless steel barrel.

Conclusion

Stainless ball type cranes are widely used in a variety of applications. This is due to their simplicity, reliability and a large selection of hull designs.

From the video in this article, you can get more information on this topic.