Storm wells: construction objectives, types, materials used

In what cases a storm sewer is constructed of a closed type? What are the rainwater wells? What materials are they built from? Let's figure it out.

Open and closed stormwater

The difference between them is intuitive; however, let's not be too lazy to describe both systems in more detail.

Open storm sewer is a gutter (most often concrete), laid on the surface of the soil. They are laid, of course, with a constant slope of the flow of water.

The price of gutters and auxiliary materials (sand, cement, etc.) is small; However, this scheme has several limitations.

- The slope of the gutter is forced to repeat the terrain relief with minor deviations in one direction or another. Not always in this way water will be transported in the direction you want.

- Garbage, sand, branches and foliage often create an insurmountable barrier to runoff. Of course, cleaning it doesn’t pose any problems, but you definitely want to do it in a shower?

Closed stormwater completely solves the problems described.

- Slope can be created in any direction. Of course, sometimes this means a significant amount of earthworks.

- Sand traps or grids that are equipped with wells for storm sewers, do not allow large debris to clog stormwater.

By the way: understandably, they will not protect against seasonal problems with ice jams. First of all, it concerns cold regions with a significant depth of soil freezing.

In what cases is preferred each of the described schemes?

The instruction is simple and obvious.

- Open gutters - the perfect solution for a small area with a constant slope.

- Difficult terrain and large areas will force the use of underground storm sewers.

Items

What is the underground stormwater?

Pipes

It is clear that the main element is a pipe dug into the ground, which, in fact, transports water. It fits into the ground with a constant slope of about a centimeter per linear meter. At present, ordinary PVC sewage pipes with a diameter of 110 - 200 millimeters are used for household plots; in urban stormwater there is a large diameter reinforced concrete pipe.

Receiving well

What is a reception storm sewer is also quite understandable. Moreover: each of us attacked or ran into their grids many times.

Actually, we have a usual vertical shaft with a diameter of 60 centimeters, protected from debris from above. It is usually located at the lowest point of the relief area; this ensures the natural flow of water. The depth of the well (as well as the depth of the pipe laying) should exclude its freezing in transitional seasons, when a warm day may be replaced by night frosts.

Inspection well

An observation storm well is usually arranged where the sewage pipe turns or changes slope. The purpose of its construction is to provide access to network segments for cleaning, thawing and repair.

What does a manhole look like? In its simplest form, this is a vertical shaft already familiar to us with an open tray laid along the bottom, into which pipes are opened at the same level on both sides.

Curiously: a manhole can combine several pipes running from the receiving wells. In particular, its construction is highly desirable at the point of connection of branches from several sites to the collector.

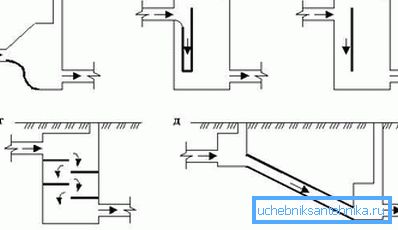

Drop well

Drop wells of storm sewers are mounted in the following cases:

- Necessity to miss the underground line. For example, when the storm sewer intersects with a water supply system laid at the same depth, a pair of drop wells allows you to bypass it higher or lower.

- The desire to force, regardless of the terrain, to create an acceptable slope for gravitational movement of rainwater.

The basic design is ridiculously simple: two pipes are displayed in the well shaft at different levels.

However, when designing a drop well, two problems must be solved:

- Falling water from a great height will create a fair amount of noise.

- In a heavy downpour and with a significant drop, a strong jet is fully capable of gradually breaking down the walls of the well.

What could be the solution?

- The water tray is made sloping, thereby eliminating the fall of water on a surface that is perpendicular to the stream.

- The supply pipe is equipped with an elongated tee, almost reaching the bottom level.

- A reflecting screen is placed in front of the inlet pipe.

- The walls of the well are equipped with several shelves for water with a small difference between them.

- Instead of one chamber, two wells are fitted, connected by a pipe with a large slope.

Applicable Materials

Can I build a storm sewer well with my own hands? Can the current market offer any ready-made solutions?

Concrete rings

They are very popular in equipping stormwater in cities.

The construction is quite technological and takes a moderate amount of time; however, for a private house this is not the best solution:

- Reinforced concrete rings are not cheap.

- For their installation you need a crane, which is also not free, and it will pass far from everywhere.

Brick

Unlike rings, brick walls are easy to lay without the use of technology. For this work you need a minimum construction experience.

Just follow a few simple rules:

- A concrete pad is formed under the wall by adding rubble.

- The wall is placed at least half a brick, with ligation of horizontal rows.

- It uses only and exclusively red brick. Silicate is rapidly destroyed in dampness, while the hollow in cold will suffer from the crystallization of water in its pores.

Above the brick well is covered with ready-made concrete tiles with a hatch.

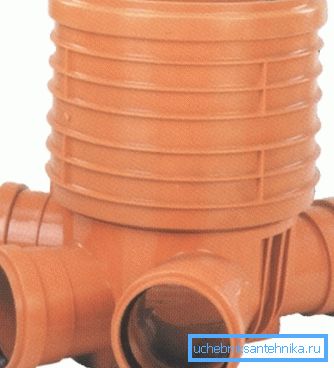

Plastic

Due to the combination of relative cheapness and durability, polyethylene and polypropylene wells are rapidly gaining popularity. Their manufacture of corrugated thick-walled pipes allows to solve the main problem of plastic - low ring stiffness.

In addition, when installing plastic wells should follow a couple of simple rules.

- With a high groundwater level, products with loading cells are preferred. During installation, they are poured with concrete and do not allow the well to float in wet ground.

- To increase the rigidity of the structure, the backfilling of smooth-wall wells is carried out with a cement-sand mixture in the proportion of 1: 5. When laying the mixture is rammed every 20 centimeters.

Conclusion

The video in this article will offer you a closer look at the storm sewer system. Successes!