Submersible well pumps for efficient water production

In connection with the development of individual construction, more and more developers are acquiring their own source of water, but high-quality well pumps are necessary for automatic liquid collection. Particular attention is paid to devices of the submersible type, as they can provide a rise from a great depth.

As for external analogues, with their help water is taken only from a distance of up to 8 meters, so these products are not considered.

Acquaintance with devices

Represented units are immersed in the pumped liquid, which makes it possible to lift from a rather large depth.. In the case of using a hydraulic motor, the pumped medium acts as an energy source, which gets inside under excessive pressure. An independent drive with this option is installed above the surface of the water.

The most important benefits

Currently, well pumps, immersed directly in the liquid, are widespread due to the many advantages.

Therefore, they began to be considered the main devices for the intake of fluid and supply it to almost any height.

- Water acts as a cooling agent, which means that overheating occurs only in exceptional cases.

- Such devices are very easy to install and dismantle if necessary.

- The high tightness of the unit avoids the ingress of water, which can disrupt the operation of the system.

- The method of direct pressure provides the ability to effectively move the fluid over long distances.

- Due to its compact dimensions, it is possible to store and transport products without any difficulties.

- These devices have low requirements for the quality of pumped water.

- In the process of operation of the unit does not create excessive noise, so it can be operated almost everywhere.

- Low price can be considered as an additional advantage, which speaks in favor of this product.

Addition! Currently, the scope of the above products has expanded to a large extent, which is primarily associated with the implementation of technical developments.

The use of such devices

Devices for fluid intake, immersed directly in the pumped medium, are used to provide private homes with water, as well as for irrigation of land.

As a rule, a well is used as a tank for the installation of the pump, but in reality the product can be located in a lake, river and other water bodies. The distance from the bottom should exceed one meter to protect the pump from the ingress of various impurities.

Main products

These products can be divided into two types, based on the principle of operation. However, there is also another classification that distinguishes between rod and rodless devices.

In the first case, the operation is carried out with the help of an independent engine located on the surface of the water. Each well pump with a float is driven through a special rod.

Vibratory aggregates

Products in this category function by changing the pressure in a special discharge chamber, and fluid is sucked in thanks to the reciprocating movements of the diaphragm made of rubber.

When the device is turned on, an electric current enters the coil winding, forming a magnetic field.

The space of the suction compartment is filled with liquid, which penetrates through special valves.

- The power unit is an electromagnet consisting of a special core, which is made of steel plates. Epoxy resin with quartz sand is used as a fill.

- The vibrator includes another part of the magnet with a fixed stem. The rubber washer serves as a shock absorber. The performance of the entire apparatus depends largely on this element.

- Suction and delivery chambers are needed for the intake of water and its subsequent delivery to a certain distance.

- Special shock absorber, which in some cases is closed with a metal ring.

- With the help of washers (by changing their number), you can adjust the stroke of the piston, and therefore, adjust the performance.

- The rod moves inside the chamber along the guide in the form of a ring. The design with an elongated part somewhat improves performance, because in this case there is practically no lateral displacement.

- Non-return valves in the form of rubber inserts allow the liquid to flow inward, but not out of the chamber, since the hole closes when the piston acts.

- A rubber piston with a locking nut is the basic component of this design, which often breaks. Especially quickly disables the element of dirty water.

- Outlet channels are necessary so that when the pressure inside the cavity increases, water can flow out.

Note! Of all the listed components, a rubber piston and check valves are more susceptible to wear. As for the other components, they are quite durable.

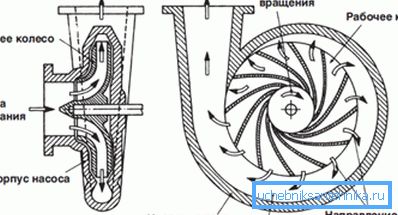

Centrifugal products

Today, well pumps of this type are considered to be a very common kind of hydraulic machines.

The main advantage is the continuous flow of the pumped medium, which is driven by the creation of centrifugal force.

- The main camera, which is a special capacity where the whole process takes place.

- The impeller is fixed on the shaft using a key and a cap nut.

- To help in the transmission of fluid energy help special blades located between the discs and the hub.

- The body allows you to connect the main fragments into a single hydraulic system.

- The gland includes a kind of sleeve, o-rings, gaskets and a pair of studs with nuts.

- Nozzles are required for fluid intake and forcing a certain pressure inside the system.

- The shaft of the device in most cases is made of stainless steel, as you have to deal with a liquid medium.

- Bearings of such pumps are supplied mainly with cast iron liners with a special casting.

- The guide is cast from cast iron, although the variant with bronze is considered more preferable, because it allows to get an absolutely smooth surface.

Attention! To increase the head at relatively low feed rates, multistage pumps with horizontal position are used. They are equipped with several impellers.

Installation process

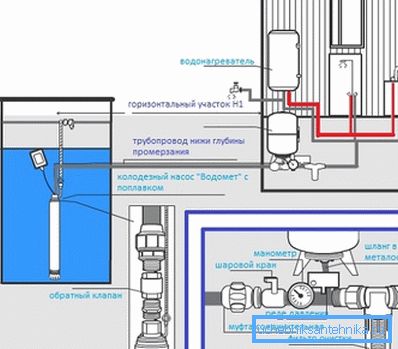

After purchasing an immersion product, many questions arise regarding the installation of the device. However, in fact, the connection scheme of the well pump is quite simple, so the work is often done by hand. It is desirable to have at least one assistant.

Main scope of work

The submersible-type device is held inside with a cable, which must be attached to a sturdy and reliable construction. The best option is to make from the corners of the metal frame, which is installed directly on the tip.

One of the elements makes a hole for fixing the cable.

- First, the device is placed next to the pipe section, through which the connection with the tee will be carried out.

- Next is unwinding the cable to connect to the electrical network. It is also located in the immediate vicinity of the pipe.

- The inlet of the device is supplied with a check valve, but sometimes they are installed at the factory.

- A brass or plastic coupling is attached to the installed valve, for connecting to a water pipe.

- The electrical cable is also fixed to the element of the water supply system, for which electrical tape is used.

- The pump is suspended on a galvanized or nylon cable. The supporting element is threaded into the eyelets located on the housing.

- After pre-fixing the device is lowered into the well by two people, while you can not hold on to the electrical cable.

- When the device reaches the desired depth, the other end of the cable is attached to the steel frame through the prepared hole.

Note! Usually after installation, the pipeline is laid to the place of installation of plumbing equipment. After assembling the system, components located underground are covered with geotextiles.

Connection of the hydroaccumulator and automation

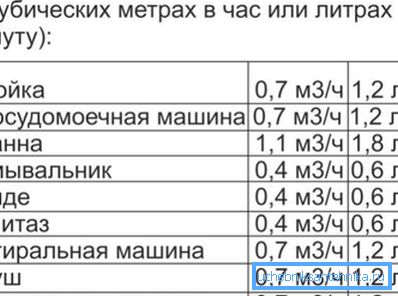

To automate the operation of the unit, making the work more comfortable, a special relay and membrane tank are installed. The hydroaccumulator allows not to switch on very often when the faucet of the sanitary device opens. Water in such a container is enough, as a rule, for several hours.

All elements are installed indoors. The relay is installed in a horizontal position so that condensate does not leak into the interior. Electrical cables are necessarily protected with a special corrugation.

Basics of operation

In most cases, the devices are fully adjusted, but before installing it is recommended to test the device anyway for the absence of distortions and jams, because during transportation damage may occur.

To do this, remove the mesh filter, and using the knob turns the clutch.

In this case, the rotor should rotate smoothly.

- In the absence of any data, it is necessary to observe the condition that the unit used is below the water level, and the distance from the surface must exceed one meter.

- It is not recommended to operate the device without electrical safety equipment that protects the main motor from overloads, short circuits, as well as two-phase switching.

- When starting the system, the valve located on the discharge pipe closes completely. The main task of the testing inclusion is to verify the correctness of the rotor.

- If the device is functioning normally, the control valve opens gradually. However, in no case should it exceed the flow rate of the fluid source.

- The first three days are carefully monitored for the operation of the well pump. If during this time no malfunctions are detected, the device is put into continuous operation.

- About once a month, the control station is checked, or rather, the state of the contacts and the relay is examined. Burnt items are gently wiped with a cloth that has been treated with alcohol.

- Observation of the condition of the pumping product is carried out by indirect signs. For example, an increase in the dynamic water level with increased performance may indicate a malfunction of the apparatus.

- Before descending, the pump in many cases is filled with filtered water through the filling opening. Initial start-up without this action is carried out only two hours after the dive. (See also the article How to choose a pump for a well: parameters.)

As a conclusion

The instruction manual, which was presented above, considers well pumps of the submersible type, since they are considered to be the most efficient and most convenient during the operation. Preventive and repair activities are carried out with different frequency, and it all depends on the specific model. The video in this article gives you the opportunity to get the most complete information about the devices.