Surface pump for a well: characteristics, features,

Surface pumps for wells allow pumping water from a shallow depth, which is important for owners of country houses and suburban areas.

We will talk about the main characteristics and features of these devices, as well as show how to install the surface pump in the well.

Surface pump

Device and purpose

Surface pumps work on the principle of sucking water by creating a vacuum at the end of the suction hose, which is dipped by the other end into the water. Thus, there is a difference in pressure at different ends of the hose, and at full vacuum at the suction side it will be the value of atmospheric pressure, that is, about 760 mm Hg.

If we replace the mercury column with a water column, then the height of such a column will be 10.3 meters, which means that with a full vacuum on the suction side, the water can rise by no more than 10.3 meters.

Taking into account the friction losses of water against the pipe walls and an incomplete vacuum in the system, the maximum height of the water of such a pump will be no more than 9 meters, and if you take into account the horizontal part of the suction pipe, it turns out that the real working height will be 7 - 8 meters.

Note! When calculating the parameters, consider the distance from the well of the surface pump. Here the following formula would be appropriate: Y = 4 (8-X), where Y is the length of the horizontal part of the pipe, X is the suction height. That is, four meters of the horizontal part are equivalent to one meter of lift.

Note! From the above calculation we can conclude that the surface pump is designed to lift water to a height of up to 8 meters. This allows you to use this device for water intake from open water bodies, shallow sand wells and wells.

By design, external pumps are divided into three main types:

- Whirling. The most compact and inexpensive devices capable of creating a sufficiently high pressure in the system, but they have low efficiency - no more than 45%. They are used mainly for irrigation and pumping water from flooded premises, but low efficiency and low reliability do not allow us to recommend this type of equipment as a permanent unit for an autonomous water supply system;

- Centrifugal. More expensive and reliable devices that create at least less than the vortex, but ample pressure to ensure the work of the plumbing. They have high efficiency - up to 92% - with sufficient reliability for continuous use, which allows using this type of equipment in the operation of water supply pumping stations;

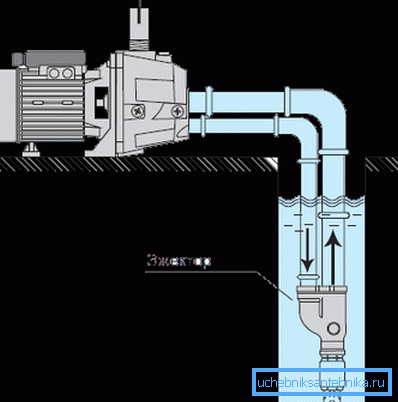

- Ejector. They have two water circulation circuits: in the first circuit, the liquid is supplied to the ejector nozzle, where due to the Bernoulli effect a pressure difference is created and water is sucked from the external environment - the second circuit. This solution allows you to lower the ejector to a depth and solve the issue of limiting the suction height, but now for this purpose they use more efficient submersible units, the price / quality ratio of which is higher.

As we see, centrifugal pump designs turned out to be the most practical, therefore we will dwell on them in more detail.

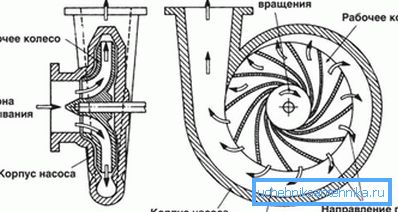

Arranged centrifugal unit is quite simple:

- Two drives are rigidly fixed on the gearbox drive shaft, in the center of one of which there is a hole;

- The hole communicates with the inter-disk space, where inclined plates are soldered, creating channels from the center of the space to its edges, which are connected to a collector tank (diffuser) that communicates with the supply hose;

- A suction hose is connected to the hole in the center of the disc;

- If the suction hose and the interdisk space are filled with liquid and the gear drive is set in motion, then the blades inclined in the direction opposite to the rotation will start pushing water from the center to the edges of the space between the discs due to centrifugal force;

- As a result, a vacuum will be created in the area of the center of the wheel and the intake port, and in the region of the edges and communicating with the discharge hose of the diffuser - an area of increased pressure;

- Under these conditions, the system will strive for equilibrium, and water will be pushed out by pressure from the accumulation tank at the edge of the wheel into the discharge hose, while a vacuum will arise in the center of the wheel and fluid will flow out of the suction hose under atmospheric pressure.

As a result, a continuous circulation is created and water is pumped from one point to another, which was what was required to achieve. However, for work in the autonomous water supply system of the house, the surface unit is not independently used from the well, but a so-called pump station is assembled, which is described in more detail in the next paragraph.

Pumping station

For normal operation of the surface pump as part of the water supply system of a dwelling house, it is connected to an accumulation tank and an automatic activation control system. This is necessary in order to reduce the number of unit starts per unit of time.

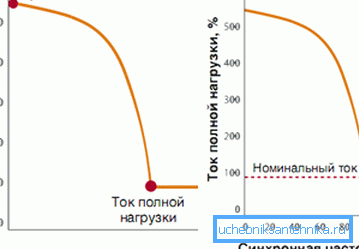

The fact is that when you turn on the power on the motor winding, peak values of the magnitude of the current appear, which are called inrush currents. These currents cause a destructive effect on the device, therefore, from the point of view of the working resource of the electric motor, it is much better that it works with the smallest number of start-off cycles.

On the other hand, the constant operation of the pump is not necessary and is unprofitable economically, since it consumes a considerable amount of energy and empties the well. Obviously, it is necessary to create a certain amount of water and pressure in the system, which will cover the constant on-off plumbing fixtures and taps, and only when this pressure drops below certain values the pump will turn on and restore the reserve.

Accordingly, when a certain peak pressure is reached in the storage tank, the pump will automatically shut down.

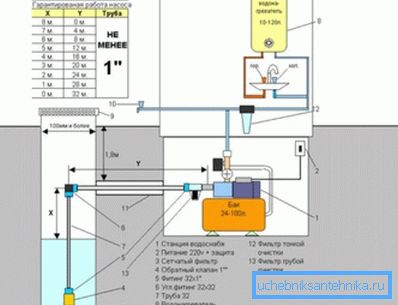

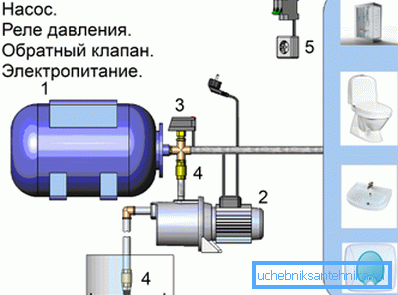

So we came to the device of the pumping station, and its main parts are:

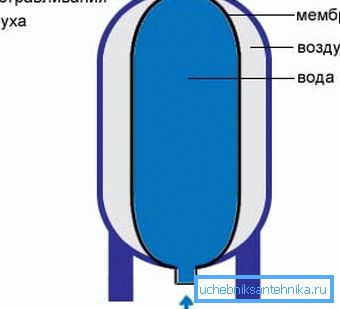

- Hydroaccumulator or receiver. It is a metal or plastic tank, inside which is a rubber bulb (membrane). Around the pear is compressed to 3.5 atm. air and water supplied to the pear is under constant pressure;

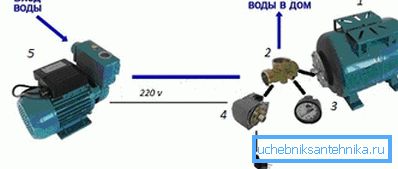

- Pressure switch. It is set to lower and upper tripping values, and when the lower limit is reached, the terminals close the circuit, and when the upper limit is reached, it opens. As a result, the pump power is turned on at a critical pressure drop in the tank, and when the maximum value is restored, it turns off;

- Pressure gauge. A device for measuring pressure and controlling relay settings and automation;

- Centrifugal pump;

- Suction hose with check valve and filter at the end;

- The giving (forcing) hose;

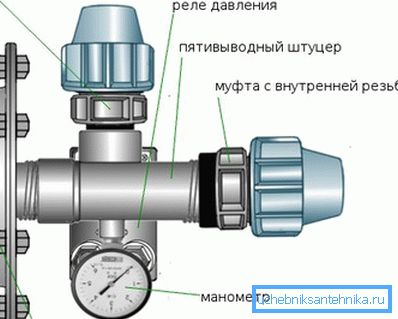

- Five-pin choke. Required for switching all the listed parts into one system.

Note! With a sufficient accumulative receiver, the system will rarely turn on the pump, which will significantly prolong its service life, as well as extend the service life of motor starters and terminal blocks. In addition, in the plumbing system there will be no pressure peaks and their characteristic water hammer, which will protect the valves and pipe connections.

Connecting the pumping station to the well

If you plan to connect the surface pump to the well with your own hands, our step-by-step instruction will help you:

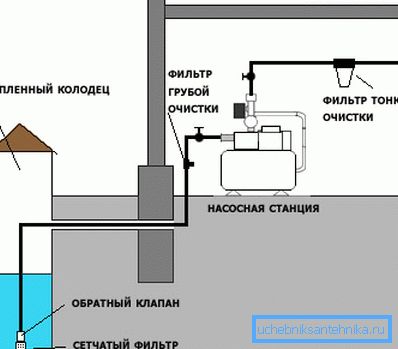

- The pumping station (or separately the pump) is installed on a firm fixed base and the legs are fixed with bolts or anchors. It is recommended to install a rubber mat under the installation to reduce the vibration activity of the device;

- The output (supply) opening of the pump is connected to the inch output of the five-terminal fitting with a hose or directly;

- The hydroaccumulator tank is also connected to the inch outlet of the choke using a soft hose or directly;

- The remaining inch hole fitting is connected to the pipe of the internal water supply at home;

- To the hole? inches on the fitting screw pressure gauge;

- The pressure switch is attached to the remaining unused last hole of the nozzle;

- The suction port of the pump is connected to the water intake pipe;

- The end of the water intake pipe is provided with a check valve and a coarse water filter and lowered into the well (the distance to the bottom is at least one meter);

- The power cord of the pump is connected to the normally open terminals of the pressure switch, and the relay itself - to the mains socket 220 V;

- The working space of the pump is filled with water through a special hole in the housing and the device is started up;

- Cranes in the house are closed and waiting for filling the tank. When the tank is full, and the pump is turned off, cut off pressure on the pressure gauge;

- Then the taps are unlocked and the water is released until the pump is turned on again. Including pressure switch;

- Finally, compare the obtained pressure values with the passport data of the receiver and, if necessary, adjust the pressure switch.

Note! All joints of the fitting with the pipes should be provided with coupling with cap nuts, and between the fitting and the tank, as well as between the fitting and the water pipe should be embedded ball valves.

Conclusion

Surface pumps are widely used in autonomous water supply systems for supplying water from shallow wells and wells. With the help of our guide, you will be able to independently connect and establish a system for delivering water from a well or other source. You can study the issue more deeply with the help of the video in this article.