Surface pumps for wells: design and installation

Water wells are designed to raise to the surface the fluid in the lower layers of the earth. At the same time, it is necessary to say that not all of them have sufficient own pressure for the moisture to flow by gravity. It is for these cases that a surface pump for the well was developed.

Completion and installation

First you need to remember that products of this type are used only for shallow trunks. If the length of the well reaches 15 meters, then it is more rational to use submersible pumps. So power consumption will be less and do not need to use very powerful and expensive units.

Types and equipment

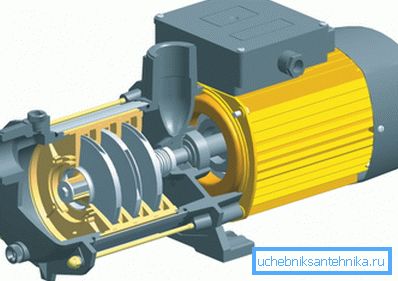

- First of all, it is worth noting that there are many different types of such devices. All of them are distinguished by their power, working depth and equipment (see also the article Pumping station for a well: device, types, installation).

- Given this diversity, special attention should be paid to the whole pumping units or blocks. They are whole complexes that do not need additional systems and can work immediately after installation.

- First of all, you should pay attention to the power of the unit and its working depth. Such data must contain an instruction manual for the product. They are selected in accordance with the technical characteristics of the well, namely with its depth of the aquifer.

- Also, such nodes are immediately equipped with a pressure switch. It is necessary so that the user can set the pressure of water he needs, which will flow into the system.

- After that you should pay attention to the hydroaccumulator. The fact is that most surface pumps come with it.

- This product performs the functions of a kind of receiver. It is filled with a certain volume of water, in which it maintains a certain pressure even after the pump is turned off. When the pressure drops above the set relay parameter, set on the accumulator, again turns on the unit.

- This reduces the number of pump motor start-ups, which significantly prolongs its service life, since a high starting current flows to the primary winding less frequently.

- It is worth saying that the duration of the system operation without switching on depends on the volume of such a battery. However, some masters recommend purchasing an additional device of this type, which is to increase this time interval.

- At the entrance to the system, some manufacturers immediately install a special filter. Its purpose is to prevent large particles from entering the blades of the device.

- Usually the price of such a unit is quite high. However, if you purchase all its elements separately and then assemble them, then it turns out that all costs are fully justified, and the finished assembly contains exactly those elements that are ideally combined with each other.

Tip! When purchasing a surface type pump it is necessary to take a device that can operate with a greater depth than that which is present in the well. So significantly reduce the load on the engine, which will increase the life of the product.

Installation

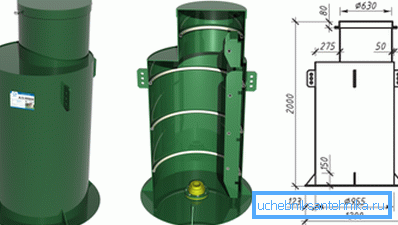

- First of all, it should be said that the installation of a surface pump on the well is carried out in close proximity to it. That is why many masters prefer to mount this device in the caisson.

- First you need to dig a hole around the casing. Its dimensions must correspond to the created caisson.

- Professionals for this stage of work recommend the use of plastic construction. They are more practical, more reliable and have a lower cost if you take into account the subsequent installation.

- It must be said that all water systems in the caisson are located below the level of soil freezing. Therefore, the casing should protrude 20 centimeters from the ground.

- The bottom of the resulting structure is best to pour concrete to get a kind of anchor and a solid foundation for subsequent installation.

- If the work is done by hand, it is worth further studying the instructions for the selected type of pump, since some models have their own installation features.

- Usually, the unit is installed on a concrete base and fixed with bolts or special impact dowels. It is worth mentioning that it is necessary to use rubber gaskets at the interface. They must compensate for the vibration emanating from the operating device.

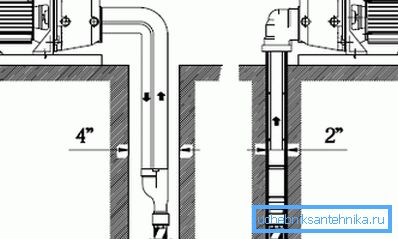

- Some pumps of this type are equipped with their own hoses or sets of pipes that must be immersed in the bottom of the well. At the same time, professionals recommend not to forget about the mesh filter, which should be included in such a delivery.

- First, the aquifer of the system is completely immersed at the bottom of the well, and then lifted by one meter.

- For fixing take a special cover, which is mounted on the casing. It should be tightly bolted through the rubber seal.

- It is worth mentioning that at the input to the system, you must put a check valve, which will prevent water hammer.

- If the pump unit was sold as an independent device, then the pipeline system should be made independently.

- A pipe is connected to the outlet of the surface unit, which will supply water to the house. At the same time, the electric power cable of the unit is brought out or put underground in a separate trench and protective corrugation.

- Connect the product to the power through a separate machine. In this case, it is worthwhile to worry in advance about the creation of grounding or to include in the power supply system ACS.

Tip! If the installation is done for the first time, it is worthwhile to additionally consult a specialist or invite professionals for this business. Otherwise, you can make a mistake that can damage not only the pump, but also the well itself.

Conclusion

By viewing the video in this article, you can get detailed information about pumps for wells designed to work on the surface. At the same time, based on this text, it should be concluded that it is best to purchase a complete assembly as an assembly, rather than independently select and assemble all components. At the same time, the installation itself is quite simple, but it requires certain theoretical training related to the type of specific pump (see also the article Connecting a well to a house: tips and recommendations from experts).