The device of a well - a structure and construction

All owners of country houses and suburban areas are well aware of how important an element for comfort and livelihood is the availability of a fresh water source for drinking and technical use. The device of a well for water - an obligatory stage in construction of the private house

Equally important is the presence of a well for sewage and equipment drainage system. The drainage system can serve not only as an additional source of process water, but also as a protection of the main structure from seasonal groundwater increases, which can flood basements and destroy the structure’s underlying foundation.

Types of wells and scope

The well itself is a universal construction, which is used everywhere in the modern world and no construction can do without it. A well is an artificially dug mine. Depending on the purpose, the mine may have different depths and may have different variants of internal arrangement..

In modern construction wells are used for such purposes as:

- organizing a freshwater source from groundwater aquifers;

- arrangement of sewage system;

- installation of drainage systems;

- installation of fire hydrants.

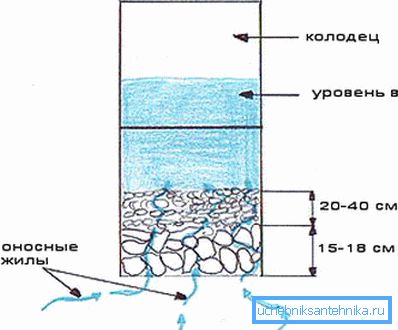

Mines for the extraction of fresh water are digging to the nearest aquifer, which provides the necessary quality of liquid for its use in food. The walls of the mine are made of monolithic concrete or reinforced concrete rings, the joints between which are carefully sealed to seal against ingress of dirty water from the upper layers of soil.

The device of the bottom of the well usually consists of a thick layer of crushed stone of a large or medium fraction, which serves as a natural filter and purifies water from small particles of sand.

In sewer systems that are designed to remove sewage and human waste products, similar wells with sealed walls of the mine are used to prevent contamination of surface groundwater. The bottom in such wells, as a rule, is hermetically closed, and the transportation of sewage is carried out via pipelines to sewage treatment plants.

Such hermetic systems are used in the removal of sewage from various industrial enterprises, where hazardous chemical compounds or other substances harmful to the nature can be present in the liquid that is removed.

However, there are also such types of sewage wells, where the separation of liquid from heavy elements takes place, while the liquid is discharged into the soil through special openings in the mine, and heavy sludge remains for their subsequent extraction and disposal.

The device of drainage wells is carried out to ensure the removal of groundwater from the foundation of the building in order to prevent destructive effects on it. Such systems are installed both on private areas of country houses and on city streets, where we can observe perforated cast iron grates in the asphalt or near the curbs.

In many large cities with developed communications and infrastructure, along with urban drainage systems, we can observe the presence of wells with fire hydrants. The device of a fire hydrant in the well (photo) allows quick access to an unlimited source of water under high pressure used by fire brigade on arrival at the fire site.

The presence of such systems allows fire brigades to effectively deal with fires of any scale, regardless of the amount of water in the car's tank.

Consider the device and the principle of action of drainage systems, since they are considered the most versatile and at the same time simple to install and use.

Types of drainage systems

Very often, the drainage system is confused with the sewage system, and there are reasons for this, since often in order to save money, the wastewater disposal system is combined with the groundwater removal system and it is no longer possible to call it drainage. This is not considered a gross violation, although it is not recommended.

Drainage systems for design are conditionally divided into three types:

- closed type;

- open type;

- combined, (combining open and closed type in separate areas).

Closed systems are designed for removal of groundwater and their collection in special wells for further use for technical purposes. Open drainage systems are designed to collect surface water after rainfall and their drainage to drainage wells.

Types of drainage wells

Before you equip the drainage system on your site, you need to know how the well is arranged, and understand all the stages of its construction.

Each well is considered to be an engineering-technical structure, which is a special tank installed in the soil and consisting of such parts as:

- vertical shaft;

- bottom of the well;

- inspection hatch.

According to the functionality and installation site, the wells are divided into several types:

- inspection or revision well;

- filter well;

- cumulative;

- turning.

Inspection wells do not accumulate wastewater, but serve to monitor the condition of the highway in all its sections, as well as for ease of cleaning in case of clogging. Most often, manholes are used at the same time as turning points, since it is in these areas that the possibility of clogging is very high.

For your information: Filter wells are installed on those sections or highways where it is not possible to discharge wastewater to special accumulators or to open rivers or reservoirs. These types of wells are also called absorption, because they filter wastewater and divert them into the ground at a safe distance from the foundation or source of fresh water.

The device of the bottom of the well is carried out with the help of a thick layer of compacted gravel, which serves as a natural filter.

Making the well yourself

In most cases, a drainage well in a private house can be equipped with your own hands if you have the necessary tools, equipment and some theoretical knowledge.

For different types of a well various construction materials are used such as:

- plastic;

- concrete rings.

The device of a drainage well from concrete rings (photo) can be carried out in two ways. If there are rings of large diameter, a person can be inside and independently dig the ground, ensuring the lowering of concrete rings under its own weight.

As soon as the first ring has leveled off the ground, a second ring is put on top of it and securely fastened with metal brackets to prevent movement, after which you can continue to dig, ensuring its lowering under its own weight.

This method is used in places with soft soil, where there is a high probability of its displacement or collapse of the edges of the mine.

Tip! If the soil is hard and the probability of displacement is minimal, then you can dig the mine to the full depth and then lay the required number of rings.

The advantages of concrete wells include:

- high reliability and durability;

- durability.

Of the disadvantages:

- complex process and high cost of installation;

- large proportion;

- the need to use lifting equipment.

Recently, plastic wells have appeared on the market, which are gradually replacing concrete due to a number of significant advantages.

The main positive features include:

- low cost compared to concrete;

- ease of installation;

- small specific weight;

- resistance to destructive environmental factors;

- minimum service requirements.

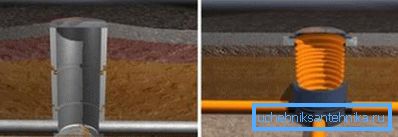

The service life of plastic products reaches at least 50 years, depending on the nature of the liquid and the presence of chemical compounds in it. In a plastic shaft, it is easy to make holes for the inset of pipes and to achieve tightness due to special rubber seals. Plastic structures have stiffeners that allow it to withstand all kinds of compression and expansion loads.

To install a plastic well, you will need:

- corrugated pipe of the desired diameter and length, which will serve as a shaft;

- plastic bottom of the shaft of the desired diameter;

- top hatch;

- rubber seals for incoming drainage pipes.

- in the casing of the mine cut openings for incoming pipes at a short distance from the bottom and install rubber seals;

Installation process

- the bottom of the shaft is fixed, the joints of the joint are coated with a sealant or bitumen mastic for sealing;

- at the bottom of the pit under the well pour concrete solution to create a solid foundation;

- the well is installed in the pit and connect the supply pipe into the holes with rubber seals;

- a mixture of gravel and sand is poured between the external walls of the mine and the pit;

- set the top hatch.

Conclusion

This completes the installation process and the mine is ready for operation. As you can see, the construction of a well in any drainage or sewage system is imperative, since without them no system can function normally and ensure the discharge of waste or groundwater in the required amount.

It is important at all stages of work with the arrangement of wells to observe the necessary security measures, use a quality tool and to withstand the requirements of the SNiP.

Before starting work, read the video in this article.