The device of the caisson on the well of concrete and metal

Drilling a water well in a country plot is the first stage of obtaining autonomous water supply. To save money on the next stage, install a metal or plastic caisson for it. No special skills are required from you, it is enough for you to understand a little in construction work.

Statistics suggest that the overwhelming number of owners of country houses use the well year round. At the same time, you need to be prepared for large temperature differences, especially in the winter period.

At this time, the well can be operated only with some limitations. The incoming water from the well to the surface freezes at low temperatures, it can ruin the pipeline and equipment.

In this case, it is necessary to ensure a stable positive temperature for the tip of the structure. To help in this will help a simple design, which is called the caisson. Arrangement of a well without a caisson is possible, but in order to use it all year round it is necessary to make a pit.

Device

There is no difference what material it is made of. Its main duty is to protect equipment from flooding with abundant rainfall or flood waters, as well as from low temperatures. You can not buy some tanks, but do it yourself if you have skills, for example, a welder.

Tightness does not allow equipment to freeze in the most severe frost. The caisson can be of any shape, and choose the size so that it can freely accommodate the necessary units with which it was convenient to work.

Materials

- Plastic is a practical option, characterized by reliable tightness and ease of installation. Insufficient rigidity of the material is compensated by pouring concrete around the perimeter.

- Concrete - a durable construction with a complex installation. It will require additional heat and waterproofing.

- The brick possesses good operational characteristics, but it is distinguished by difficult installation.

- Metal - a reliable option with durable operation. Needs additional waterproofing due to possible corrosion.

Self-production of concrete caisson

Tip: if you have a high level of groundwater at the site, then you need to thoroughly seal the object.

- Fill the bottom with concrete, and do not fill with gravel.

- Determine the dimensions of the future structure. For placement in the room the minimum is 1 mx 1 mx 1 m, in the tank it is 1.8 m high, the length of the sides is 1.5 m.

To build a concrete caisson will have in several stages.

Below is a detailed instruction.

- The device trench. Dig a casing around the casing. Pour a layer of crushed stone 150 mm high on the bottom.

- Prepare for concreting - protect the walls of the pit before starting the foundation film from groundwater.

- Install the reinforcement mesh. Depart from the walls of the pit approximately 70-80 mm and tie them with a mesh of reinforcement. Its height depends on the dimensions of the future structure. If it is impossible to pour concrete over the entire structure at once, then divide the installation into several stages. On the first one, install a row of reinforcement of the required height with a pitch of 300x300 mm.

- Form the formwork and fill it. Assemble it from used boards and bricks, cover them with plastic wrap, which will fix with a construction stapler. This will make it easier to remove the structure from the concrete. Fill the formwork with a solution consisting of cement, sand and rubble in a ratio of 1: 3: 5. During stage-by-stage concreting, it is necessary to repeat the operation of assembling the reinforcing mesh after the material has set. Pour formwork until then. Until the design reaches the desired height.

Tip: if the plan provides for the phased concrete pouring of the caisson, set the formwork to about half the height of the pit.

- Take a perforator and, after complete drying of the structure, make holes in the walls of the caisson in order to insert water pipes into it through them.

Tip: put it on the pipeline at the point of passage through the concrete sleeves made of metal. Fill the distance between the pipe and the liner with mounting foam, between the liner and the concrete with mortar.

- Manufacturing formwork for the cover. The design will represent a wooden shield to be laid on the bars. For manufacturing pick up durable material:

- put 6 bars on boards;

- top with more bars;

- twist all the screws;

- attach to the formwork board;

- Provide a hole for the hatch to install a wooden box of the desired size;

- Strengthen the structure before pouring the bottom bars.

A more durable cover can be made by adding a reinforcing bar with a 50x50 mm pitch along its perimeter. The rest of the knit in increments of about 150 x150 mm. If necessary, fasten metal leads for watering hose and ventilation to the fittings of the future cover.

- Fill the cover with concrete. Secure the hatch.

If necessary, treat its walls with a waterproofing compound, as the material is hygroscopic and insulate. In the same way settled brick caisson for the well. Only the walls are brick masonry.

Metal construction

The most popular is for the well metal caisson, the price of which depends on the cost of the material and the cost of the work of the welder. This results from the fact that this construction is easy for making independently. You will need only sheet metal, 4-5 mm thick, electric welding apparatus and skills of a welder.

The shape of the container can be in the form of a cylinder, a cube or a parallelepiped. The first option is the easiest to manufacture.

Choosing the shape of the caisson, it should be noted that the number of welds affects the overall life of the structure. These are potentially dangerous places for corrosion, so they should be as small as possible.

In the bottom of the tank it is necessary to make a hole for the casing of the well. Then weld a sleeve to it that fits easily on it. Weld into the wall of the nipple for pipes of water supply from the well. From above make the hatch for the passage inward. Inside the tank all ground, and outside - cover it with layers of bitumen mastic, which protects it from corrosion.

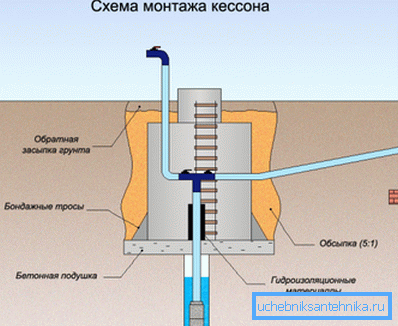

Installing the caisson for the well will not cause problems:

- Install it on the bars above the pit.

- Slide the liner over the casing.

- Remove the struts and carefully lower the structure down.

- After that, level it up.

- Route the pipes to the nipples prepared in advance and install the necessary equipment.

- Warm the upper part of the caisson, and on top of the metal hatch make an additional one insulated.

Conclusion

Although the manufacture of a caisson for a well is laborious work, but it is quite possible to do it yourself. Such designs serve for a long time and do not require special preventive measures. In the presented video in this article you will find additional information on this topic.